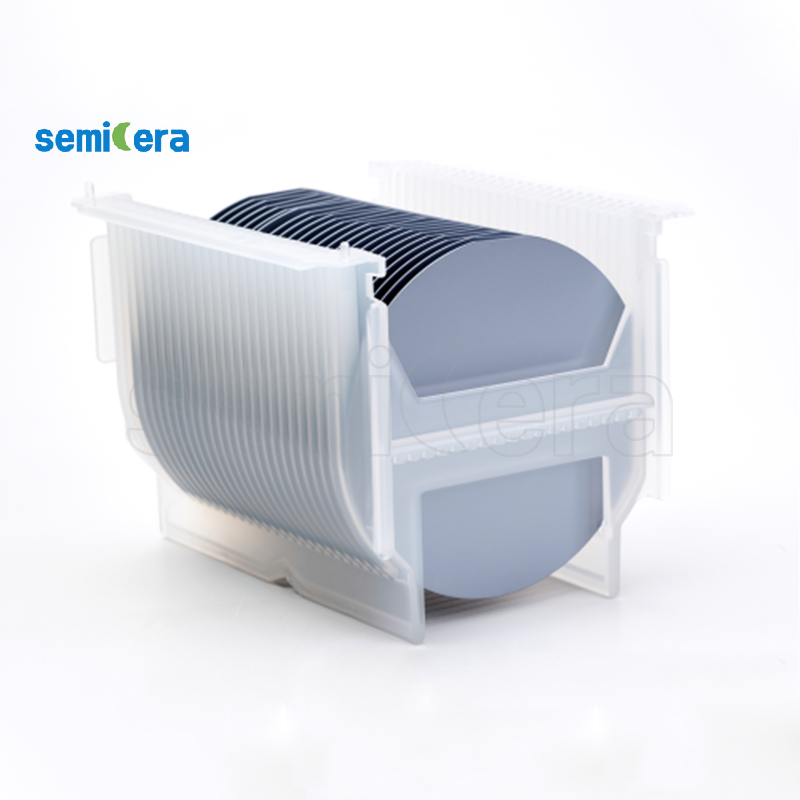

Semicerayana jin daɗin bayarwa2" Gallium Oxide Substrates, Kayan da aka tsara don haɓaka aikin na'urori masu mahimmanci na ci gaba. Waɗannan sifofin, waɗanda aka yi daga Gallium Oxide (Ga2O3), yana da babban bandeji mai fa'ida, yana mai da su kyakkyawan zaɓi don aikace-aikacen babban ƙarfi, mai ƙarfi, da aikace-aikacen optoelectronic UV.

Mabuɗin fasali:

• Ƙarfafa Faɗin Bandgap: The2" Gallium Oxide Substratessamar da bangaran banɗaki na kusan 4.8 eV, yana ba da damar haɓaka ƙarfin lantarki da aiki mai zafi, wanda ya zarce ƙarfin kayan aikin semiconductor na gargajiya kamar silicon.

•Wutar Lantarki Na Musamman: Waɗannan na'urori suna ba da damar na'urori su iya ɗaukar nauyin ƙarfin lantarki mai mahimmanci, wanda ya sa su zama cikakke ga na'urorin lantarki, musamman a aikace-aikace masu ƙarfin lantarki.

•Madalla da Thermal Conductivity: Tare da ingantaccen kwanciyar hankali na thermal, waɗannan abubuwan haɗin gwiwa suna kula da daidaiton aiki har ma a cikin matsanancin yanayin zafi, manufa don aikace-aikacen ƙarfi da zafin jiki.

•Material mai inganci: The2" Gallium Oxide Substratesbayar da ƙananan ƙarancin lahani da ingancin kristal mai girma, yana tabbatar da ingantaccen aiki na na'urorin semiconductor.

•Aikace-aikace iri-iri: Waɗannan ƙananan abubuwa sun dace da aikace-aikacen da yawa, ciki har da transistor wutar lantarki, Schottky diodes, da na'urorin LED UV-C, suna ba da tushe mai ƙarfi ga duka wutar lantarki da sababbin abubuwan fasaha na optoelectronic.

Buɗe cikakken yuwuwar na'urorin semiconductor ɗinku tare da Semicera's2" Gallium Oxide Substrates. An tsara kayan aikin mu don biyan buƙatun buƙatun ci-gaba na yau da kullun, tabbatar da babban aiki, aminci, da inganci. Zaɓi Semicera don kayan aikin semiconductor na zamani waɗanda ke motsa ƙirƙira.

| Abubuwa | Production | Bincike | Dummy |

| Crystal Parameters | |||

| Polytype | 4H | ||

| Kuskuren daidaita yanayin saman | <11-20>4±0.15° | ||

| Ma'aunin Wutar Lantarki | |||

| Dopant | n-nau'in Nitrogen | ||

| Resistivity | 0.015-0.025ohm · cm | ||

| Ma'aunin injina | |||

| Diamita | 150.0 ± 0.2mm | ||

| Kauri | 350± 25 μm | ||

| Matsakaicin firamare | [1-100]±5° | ||

| Tsawon lebur na farko | 47.5 ± 1.5mm | ||

| Filayen sakandare | Babu | ||

| TTV | ≤5m ku | ≤10 μm | ≤15 μm |

| LTV | ≤3 μm (5mm*5mm) | ≤5 μm (5mm*5mm) | ≤10 μm (5mm*5mm) |

| Ruku'u | - 15 μm ~ 15 μm | - 35 μm ~ 35 μm | -45μm ~ 45μm |

| Warp | ≤35 μm | ≤45 μm | ≤55 μm |

| Gaba (Si-face) rashin ƙarfi (AFM) | Ra≤0.2nm (5μm*5μm) | ||

| Tsarin | |||

| Yawan bututu | <1 ku/cm2 | <10 a/cm2 | <15 ku/cm2 |

| Karfe najasa | ≤5E10atoms/cm2 | NA | |

| BPD | ≤1500 ea/cm2 | ≤3000 ea/cm2 | NA |

| TSD | ≤500 ea/cm2 | ≤1000 ea/cm2 | NA |

| Ingancin Gaba | |||

| Gaba | Si | ||

| Ƙarshen saman | Farashin CMP | ||

| Barbashi | ≤60ea/wafer (size≥0.3μm) | NA | |

| Scratches | ≤5ea/mm. Tarin tsayin ≤ Diamita | Tsawon tsayi≤2*Diamita | NA |

| Bawon lemu/ramuka/tabo/tabo/ fasa/kamuwa | Babu | NA | |

| Gefen kwakwalwan kwamfuta / indents / karaya / hex faranti | Babu | ||

| Yankunan Polytype | Babu | Tarin yanki≤20% | Tarin yanki≤30% |

| Alamar Laser ta gaba | Babu | ||

| Kyakkyawan Baya | |||

| Baya gamawa | C-face CMP | ||

| Scratches | ≤5ea/mm, Tsawon tarawa≤2* Diamita | NA | |

| Lalacewar baya (guntuwar baki/indents) | Babu | ||

| Baƙar fata | Ra≤0.2nm (5μm*5μm) | ||

| Alamar Laser na baya | 1 mm (daga saman gefen) | ||

| Gefen | |||

| Gefen | Chamfer | ||

| Marufi | |||

| Marufi | Epi- shirye tare da marufi Marufin kaset mai yawa-wafer | ||

| * Bayanan kula: "NA" yana nufin babu buƙatar Abubuwan da ba a ambata ba suna iya komawa zuwa SEMI-STD. | |||