Silicon carbide (SiC) guda kristal abu yana da babban band nisa nisa (~ Si 3 sau), high thermal conductivity (~ Si 3.3 sau ko GaAs sau 10), high electron jikewa gudun hijira kudi (~ Si 2.5 sau), high rushewar lantarki filin (~ Si sau 10 ko GaAs sau 5) da sauran fitattun halaye.

Kayayyakin semiconductor na ƙarni na uku galibi sun haɗa da SiC, GaN, lu'u-lu'u, da sauransu, saboda faɗin ratar band ɗin sa (Misali) ya fi ko daidai da 2.3 volts na lantarki (eV), wanda kuma aka sani da kayan tazara mai faɗi. Idan aka kwatanta da na farko da na biyu ƙarni semiconductor kayan, ƙarni na uku semiconductor kayan suna da abũbuwan amfãni daga high thermal watsin, babban rushewar lantarki, high cikakken electron gudun hijira kudi da high bonding makamashi, wanda zai iya saduwa da sabon bukatun na zamani fasahar lantarki ga high. zafin jiki, babban iko, babban matsa lamba, babban mita da juriya na radiation da sauran yanayi masu tsauri. Yana da muhimmiyar damar aikace-aikacen a fagen tsaron ƙasa, jirgin sama, sararin samaniya, binciken mai, ajiyar gani, da sauransu, kuma yana iya rage asarar makamashi fiye da 50% a cikin masana'antar dabarun da yawa kamar hanyoyin sadarwa na broadband, makamashin hasken rana, kera motoci, Semiconductor lighting, da smart grid, kuma zai iya rage yawan kayan aiki da fiye da 75%, wanda shine muhimmin mahimmanci ga ci gaban kimiyya da fasaha na ɗan adam.

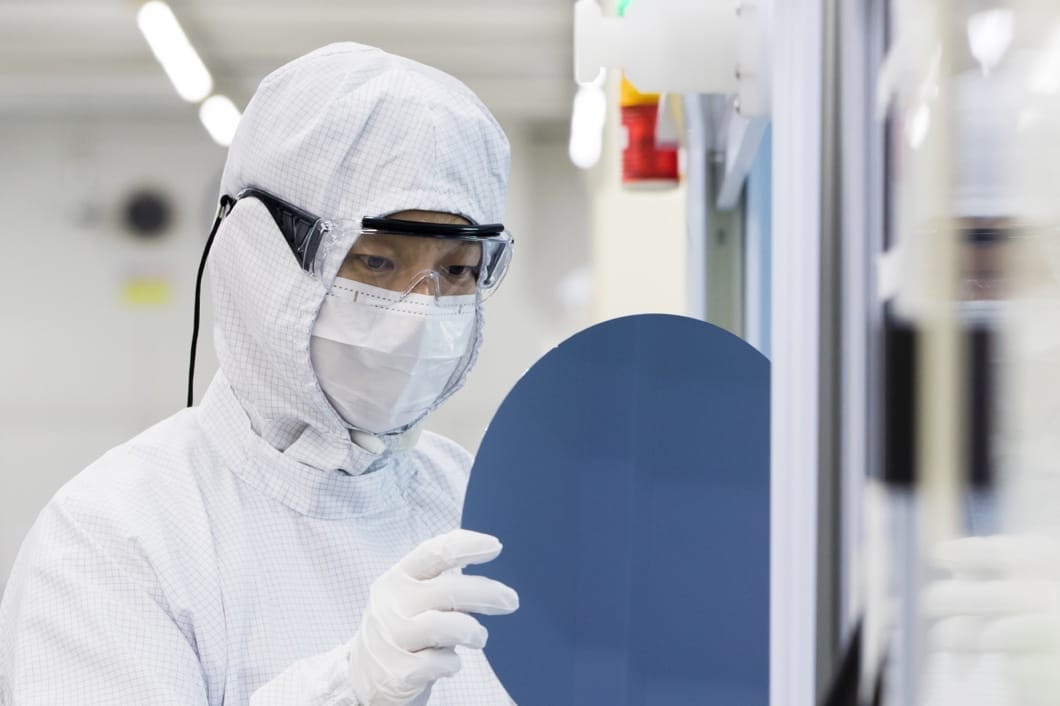

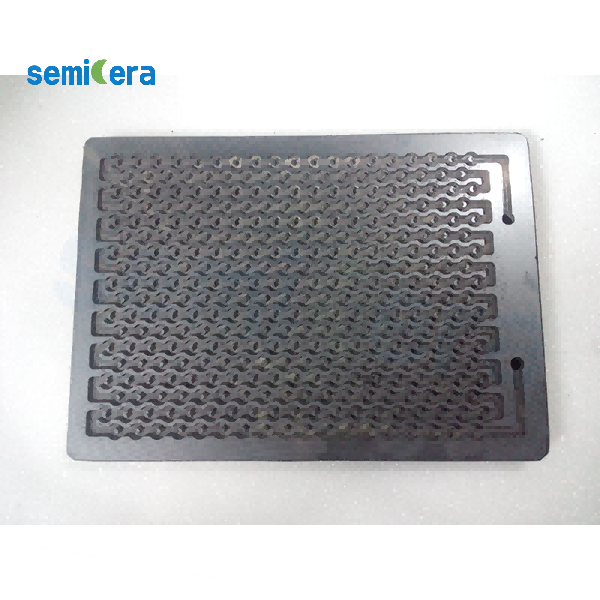

Ƙarfin Semicera na iya ba abokan ciniki tare da Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwaƙwalwa ; Bugu da kari, za mu iya samar da abokan ciniki da kama da iri-iri na silicon carbide zanen gado epitaxial; Hakanan zamu iya tsara takaddar epitaxial bisa ga takamaiman bukatun abokan ciniki, kuma babu ƙaramin tsari.

| Abubuwa | Production | Bincike | Dummy |

| Crystal Parameters | |||

| Polytype | 4H | ||

| Kuskuren daidaita yanayin saman | <11-20>4±0.15° | ||

| Ma'aunin Wutar Lantarki | |||

| Dopant | n-nau'in Nitrogen | ||

| Resistivity | 0.015-0.025ohm · cm | ||

| Ma'aunin injina | |||

| Diamita | 150.0 ± 0.2mm | ||

| Kauri | 350± 25 μm | ||

| Matsakaicin firamare | [1-100]±5° | ||

| Tsawon lebur na farko | 47.5 ± 1.5mm | ||

| Filayen sakandare | Babu | ||

| TTV | ≤5m ku | ≤10 μm | ≤15 μm |

| LTV | ≤3 μm (5mm*5mm) | ≤5 μm (5mm*5mm) | ≤10 μm (5mm*5mm) |

| Ruku'u | - 15 μm ~ 15 μm | - 35 μm ~ 35 μm | -45μm ~ 45μm |

| Warp | ≤35 μm | ≤45 μm | ≤55 μm |

| Gaba (Si-face) rashin ƙarfi (AFM) | Ra≤0.2nm (5μm*5μm) | ||

| Tsarin | |||

| Yawan bututu | <1 ku/cm2 | <10 a/cm2 | <15 ku/cm2 |

| Karfe najasa | ≤5E10atoms/cm2 | NA | |

| BPD | ≤1500 ea/cm2 | ≤3000 ea/cm2 | NA |

| TSD | ≤500 ea/cm2 | ≤1000 ea/cm2 | NA |

| Ingancin Gaba | |||

| Gaba | Si | ||

| Ƙarshen saman | Farashin CMP | ||

| Barbashi | ≤60ea/wafer (size≥0.3μm) | NA | |

| Scratches | ≤5ea/mm. Tarin tsayin ≤ Diamita | Tsawon tsayi≤2*Diamita | NA |

| Bawon lemu/ramuka/tabo/tabo/ fasa/kamuwa | Babu | NA | |

| Gefen kwakwalwan kwamfuta / indents / karaya / hex faranti | Babu | ||

| Yankunan polytype | Babu | Tarin yanki≤20% | Tarin yanki≤30% |

| Alamar Laser ta gaba | Babu | ||

| Kyakkyawan Baya | |||

| Baya gamawa | C-face CMP | ||

| Scratches | ≤5ea/mm, Tsawon tarawa≤2* Diamita | NA | |

| Lalacewar baya (guntuwar baki/indents) | Babu | ||

| Baƙar fata | Ra≤0.2nm (5μm*5μm) | ||

| Alamar Laser na baya | 1 mm (daga saman gefen) | ||

| Gefen | |||

| Gefen | Chamfer | ||

| Marufi | |||

| Marufi | Epi- shirye tare da marufi Marufin kaset mai yawa-wafer | ||

| * Bayanan kula: "NA" yana nufin babu buƙatar Abubuwan da ba a ambata ba suna iya komawa zuwa SEMI-STD. | |||