Silicon carbide (SiC) epitaxy

Tire na epitaxial, wanda ke riƙe da SiC substrate don haɓaka yanki na SiC epitaxial, an sanya shi cikin ɗakin amsawa kuma kai tsaye yana tuntuɓar wafer.

Babban rabin wata sashi ne mai ɗaukar kaya don sauran kayan haɗi na ɗakin amsawa na kayan aikin Sic epitaxy, yayin da ɓangaren rabin wata ya haɗa da bututun ma'adini, yana gabatar da iskar gas don fitar da tushe mai tushe don juyawa. suna da ikon sarrafa zafin jiki kuma an shigar da su a cikin ɗakin amsa ba tare da haɗin kai tsaye tare da wafer ba.

Da epitaxy

Tire, wanda ke riƙe da simintin Si don haɓaka yanki na Si epitaxial, an sanya shi cikin ɗakin amsawa kuma kai tsaye yana tuntuɓar wafer.

Zoben preheating yana kan zoben waje na Si epitaxial substrate tray kuma ana amfani dashi don daidaitawa da dumama. Ana sanya shi a cikin ɗakin amsawa kuma baya tuntuɓar wafer kai tsaye.

Wani mai raɗaɗi na epitaxial, wanda ke riƙe da simintin Si don haɓaka yanki na Si epitaxial, an sanya shi a cikin ɗakin amsawa kuma kai tsaye yana tuntuɓar wafer.

Ganga na Epitaxial shine mahimman abubuwan da aka yi amfani da su a cikin matakai daban-daban na masana'antu na semiconductor, gabaɗaya ana amfani da su a cikin kayan aikin MOCVD, tare da kyakkyawan kwanciyar hankali na thermal, juriya na sinadarai da juriya, dacewa sosai don amfani a cikin matakan zafin jiki. Yana tuntuɓar wafers.

| Kaddarorin jiki na Silicon Carbide Recrystallized | |

| Dukiya | Mahimmanci Na Musamman |

| Yanayin aiki (°C) | 1600°C (tare da oxygen), 1700°C (rage yanayi) |

| SiC abun ciki | 99.96% |

| Abin ciki na kyauta | <0.1% |

| Yawan yawa | 2.60-2.70 g/cm3 |

| Bayyanar porosity | <16% |

| Ƙarfin matsi | > 600 MPa |

| Ƙarfin lanƙwasa sanyi | 80-90 MPa (20°C) |

| Ƙarfin lanƙwasawa mai zafi | 90-100 MPa (1400°C) |

| Thermal fadada @1500°C | 4.70 10-6/°C |

| Ƙarfin zafin jiki @1200°C | 23 W/m•K |

| Na roba modules | 240 GPA |

| Thermal girgiza juriya | Madalla da kyau |

| Kaddarorin jiki na Sintered Silicon Carbide | |

| Dukiya | Mahimmanci Na Musamman |

| Haɗin Sinadari | SiC>95%, Si <5% |

| Yawan yawa | > 3.07 g/cm³ |

| Bayyanar porosity | <0.1% |

| Modulus na fashewa a 20 ℃ | 270 MPa |

| Modulus na fashewa a 1200 ℃ | 290 MPa |

| Hardness a 20 ℃ | 2400 Kg/mm² |

| Karya tauri a 20% | 3.3 MPa · m1/2 |

| Thermal Conductivity a 1200 ℃ | 45 w/m .K |

| Thermal fadada a 20-1200 ℃ | 4.5 1 × 10 -6/ ℃ |

| Matsakaicin zafin aiki | 1400 ℃ |

| Thermal girgiza juriya a 1200 ℃ | Yayi kyau |

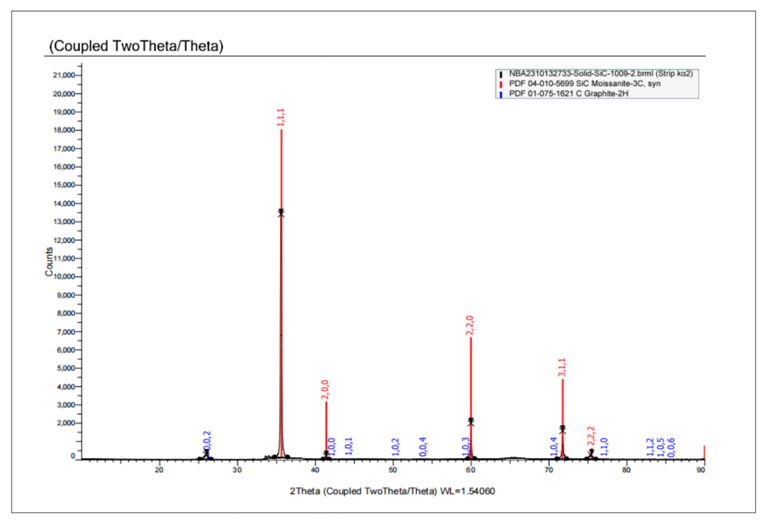

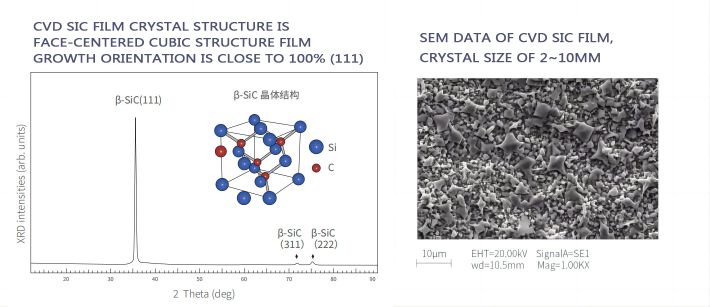

| Abubuwan asali na zahiri na fina-finai na CVD SiC | |

| Dukiya | Mahimmanci Na Musamman |

| Tsarin Crystal | FCC β lokaci polycrystalline, yafi (111) daidaitacce |

| Yawan yawa | 3.21g/cm³ |

| Hardness 2500 | (500g kaya) |

| Girman hatsi | 2 ~ 10 μm |

| Tsaftar Sinadari | 99.99995% |

| Ƙarfin zafi | 640kg-1· K-1 |

| Zazzabi Sublimation | 2700 ℃ |

| Ƙarfin Flexural | 415 MPa RT 4-point |

| Modul na Matasa | 430 Gpa 4pt lankwasa, 1300 ℃ |

| Thermal Conductivity | 300 w·m-1· K-1 |

| Fadada thermal (CTE) | 4.5×10-6 K -1 |

Babban fasali

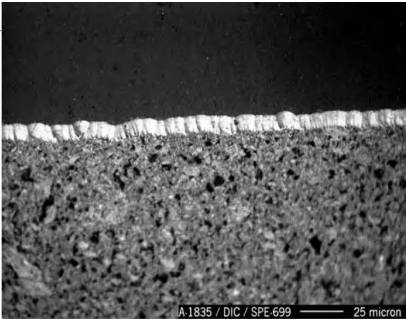

Fuskar tana da yawa kuma babu pores.

Babban tsafta, jimlar ƙazanta <20ppm, kyakkyawan iska.

High zafin jiki juriya, ƙarfi yana ƙaruwa tare da ƙara yawan zafin jiki na amfani, kai mafi girman darajar a 2750 ℃, sublimation a 3600 ℃.

Low na roba modules, high thermal conductivity, low thermal fadada coefficient, da kyakkyawan thermal girgiza juriya.

Kyakkyawan kwanciyar hankali na sinadarai, mai jurewa ga acid, alkali, gishiri, da kuma abubuwan da aka gyara, kuma ba shi da wani tasiri akan narkakken karafa, slag, da sauran kafofin watsa labarai masu lalata. Ba ya yin oxidize sosai a cikin yanayin da ke ƙasa da 400 C, kuma ƙimar iskar oxygen yana ƙaruwa sosai a 800 ℃.

Ba tare da sakin wani gas ba a yanayin zafi mai girma, zai iya kula da injin 10-7mmHg a kusan 1800 ° C.

Aikace-aikacen samfur

Narke crucible ga evaporation a semiconductor masana'antu.

Ƙofar bututu mai ƙarfi mai ƙarfi.

Goge wanda ke tuntuɓar mai sarrafa wutar lantarki.

Graphite monochromator don X-ray da neutron.

Daban-daban siffofi na graphite substrates da atomic sha tube shafi.

Tasirin murfin carbon pyrolytic a ƙarƙashin microscope na 500X, tare da tabbataccen da kuma rufe saman.

TaC shafi ne sabon ƙarni high zafin jiki resistant abu, tare da mafi high zafin jiki kwanciyar hankali fiye da SiC. Kamar yadda lalata-resistant shafi, anti-hadawan abu da iskar shaka shafi da lalacewa-resistant shafi, za a iya amfani da a cikin yanayi sama 2000C, yadu amfani a cikin Aerospace matsananci-high zazzabi zafi karshen sassa, na uku ƙarni semiconductor guda crystal girma filayen.

| Kaddarorin jiki na rufin TaC | |

| Yawan yawa | 14.3 (g/cm3) |

| Takamammen fitarwa | 0.3 |

| Ƙididdigar faɗaɗawar thermal | 6.3 10/K |

| Hardness (HK) | 2000 HK |

| Juriya | 1 x 10-5 ohm * cm |

| Zaman lafiyar thermal | <2500 ℃ |

| Girman zane yana canzawa | -10-20 |

| Kauri mai rufi | ≥220um dabi'un dabi'a (35um ± 10um) |

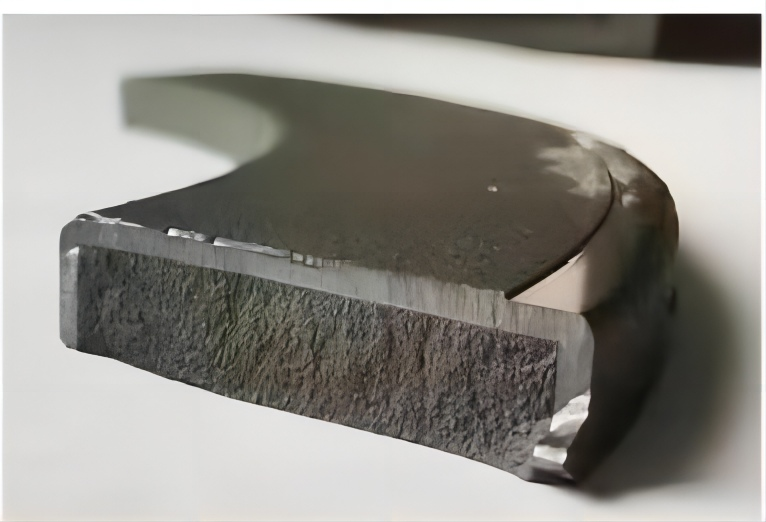

M CVD SILICON CARBIDE sassan ana gane su azaman zaɓi na farko don zoben RTP/EPI da sansanoni da sassan rami etch na plasma waɗanda ke aiki a babban tsarin da ake buƙata yanayin yanayin aiki (> 1500 ° C), buƙatun don tsabta sun fi girma (> 99.9995%) kuma aikin yana da kyau musamman lokacin da sinadarai na juriya ya yi girma musamman. Waɗannan kayan ba su ƙunshi matakai na biyu a gefen hatsi ba, don haka abubuwan da ke cikin su suna samar da ƙarancin barbashi fiye da sauran kayan. Bugu da kari, ana iya tsabtace waɗannan abubuwan haɗin gwiwa ta amfani da HF/HCI mai zafi tare da ƙarancin lalacewa, yana haifar da ƙarancin barbashi da rayuwar sabis mai tsayi.