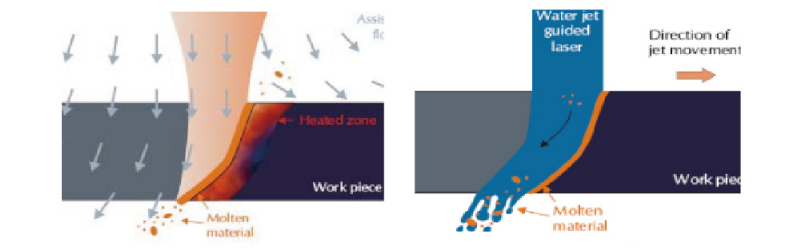

LASER MICROJET (LMJ)

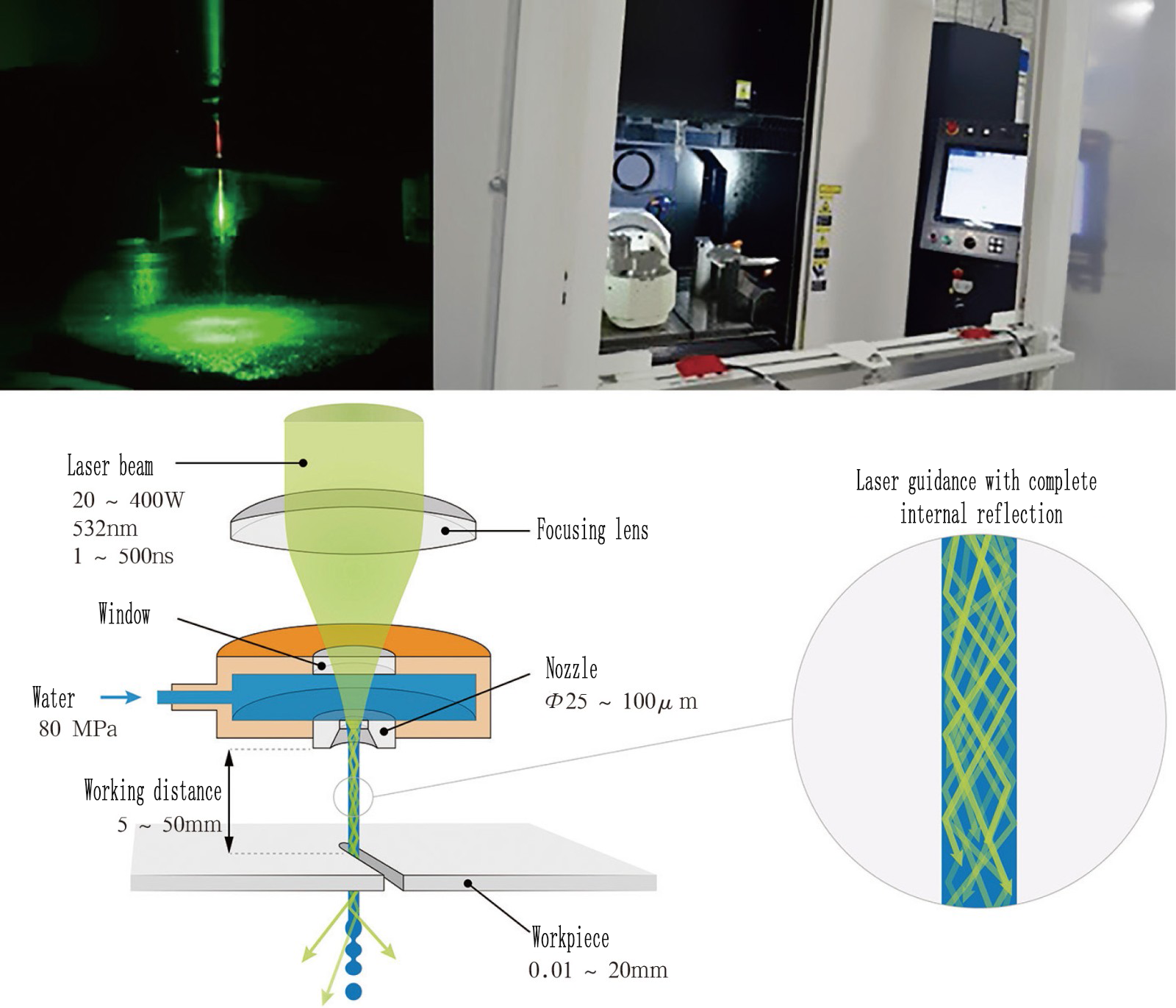

The mayar da hankali Laser katako ne guda biyu a cikin high-gudun ruwa jet, da kuma makamashi katako tare da uniform rarraba giciye makamashi da aka kafa bayan cikakken tunani a kan ciki bango na ruwa ginshiƙi. Yana da halaye na ƙananan nisa na layi, babban ƙarfin makamashi, jagorancin sarrafawa da raguwa na ainihi na yanayin zafi na kayan da aka sarrafa, samar da kyakkyawan yanayi don haɗawa da ingantaccen kammala kayan aiki mai wuya da gaggautsa.

Laser micro-water jet machining fasahar daukan amfani da sabon abu na jimlar tunani na Laser a dubawa na ruwa da kuma iska, sabõda haka, da Laser ne guda biyu a cikin barga ruwa jet, da kuma high makamashi yawa a cikin ruwa jet da ake amfani da cimma. cire kayan abu.

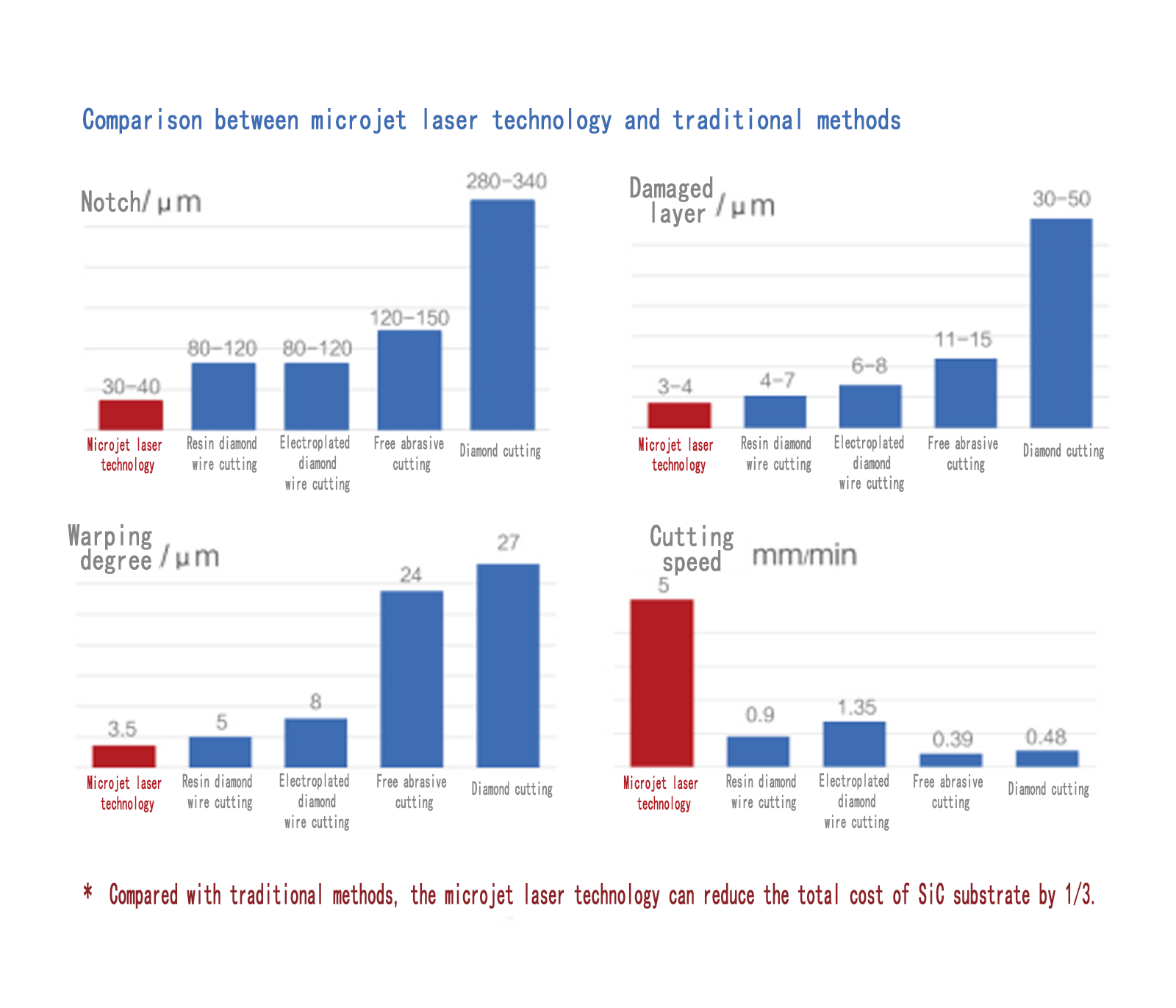

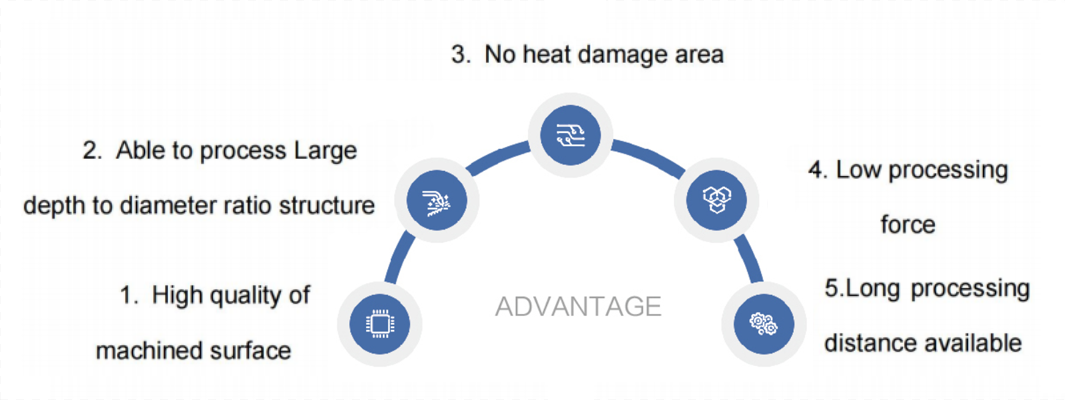

FALALAR MICROJET LASER

Fasahar Laser Microjet (LMJ) tana amfani da bambancin yaduwa tsakanin ruwa da halayen gani na iska don shawo kan lahani na asali na sarrafa Laser na al'ada. A cikin wannan fasaha, bugun jini na Laser yana nunawa sosai a cikin jet ɗin ruwa mai tsabta da aka sarrafa ba tare da damuwa ba, kamar yadda yake cikin fiber na gani.

Daga hangen nesa na amfani, manyan fasalulluka na fasahar laser microjet LMJ sune:

1, da Laser katako ne cylindrical (a layi daya) Laser katako;

2, bugun jini na Laser a cikin jet na ruwa kamar jigilar fiber, ana kiyaye dukkan tsari daga kowane yanayi na muhalli;

3, Laser katako yana mayar da hankali a cikin kayan aikin LMJ, kuma babu wani canji a cikin tsayin tsayin da aka yi amfani da shi a lokacin duk aikin sarrafawa, don haka babu buƙatar ci gaba da mayar da hankali a yayin aikin sarrafawa tare da canji a cikin zurfin sarrafawa. ;

4, ban da zubar da kayan da aka sarrafa a daidai lokacin kowane aikin bugun jini na Laser, kusan 99% na lokaci a cikin kewayon lokaci guda daga farkon kowane bugun jini zuwa sarrafa bugun jini na gaba, kayan sarrafa yana cikin ainihin gaske. -lokacin sanyaya na ruwa, don haka kusan kawar da yankin da ke fama da zafi da remelt Layer, amma kula da babban ingancin aiki;

5, ci gaba da tsaftace saman.

Rubutun na'ura

Lokacin yankan Laser na gargajiya, tarawa da gudanar da makamashi shine babban dalilin lalacewar thermal a bangarorin biyu na hanyar yanke, kuma laser microjet, saboda rawar da ginshikin ruwa, zai yi saurin kawar da ragowar zafin kowane bugun jini. ba zai tara a kan workpiece, don haka yankan hanya ne mai tsabta. Don hanyar gargajiya "yanke ɓoye" + "tsaga" hanya, rage fasahar sarrafawa.