Hanyoyin shafawa na photoresist gabaɗaya an raba su zuwa suturar juzu'i, suturar tsomawa da murfin yi, daga cikinsu akwai abin da aka fi amfani da shi. Ta hanyar jujjuyawar jujjuyawar, ana ɗibar photoresis a kan substrate, kuma ana iya jujjuya substrate cikin babban sauri don samun fim ɗin hoto. Bayan haka, ana iya samun fim mai ƙarfi ta hanyar dumama shi a kan farantin zafi. Rubutun juzu'i ya dace da sutura daga fina-finai masu bakin ciki (kimanin 20nm) zuwa fina-finai masu kauri na kusan 100um. Siffofinsa suna da kyau iri ɗaya, kauri na fim ɗin na yau da kullun tsakanin wafers, ƙarancin lahani, da sauransu, kuma ana iya samun fim ɗin tare da babban aikin shafi.

Spin shafi tsari

A lokacin jujjuyawar jujjuyawar, babban saurin juyawa na substrate yana ƙayyade kauri na fim ɗin hoto. Dangantakar da ke tsakanin saurin juyawa da kaurin fim kamar haka:

Spin=kTn

A cikin dabara, Spin shine saurin juyawa; T shine kauri na fim; k da n sune akai-akai.

Abubuwan da ke shafar tsarin suturar juyawa

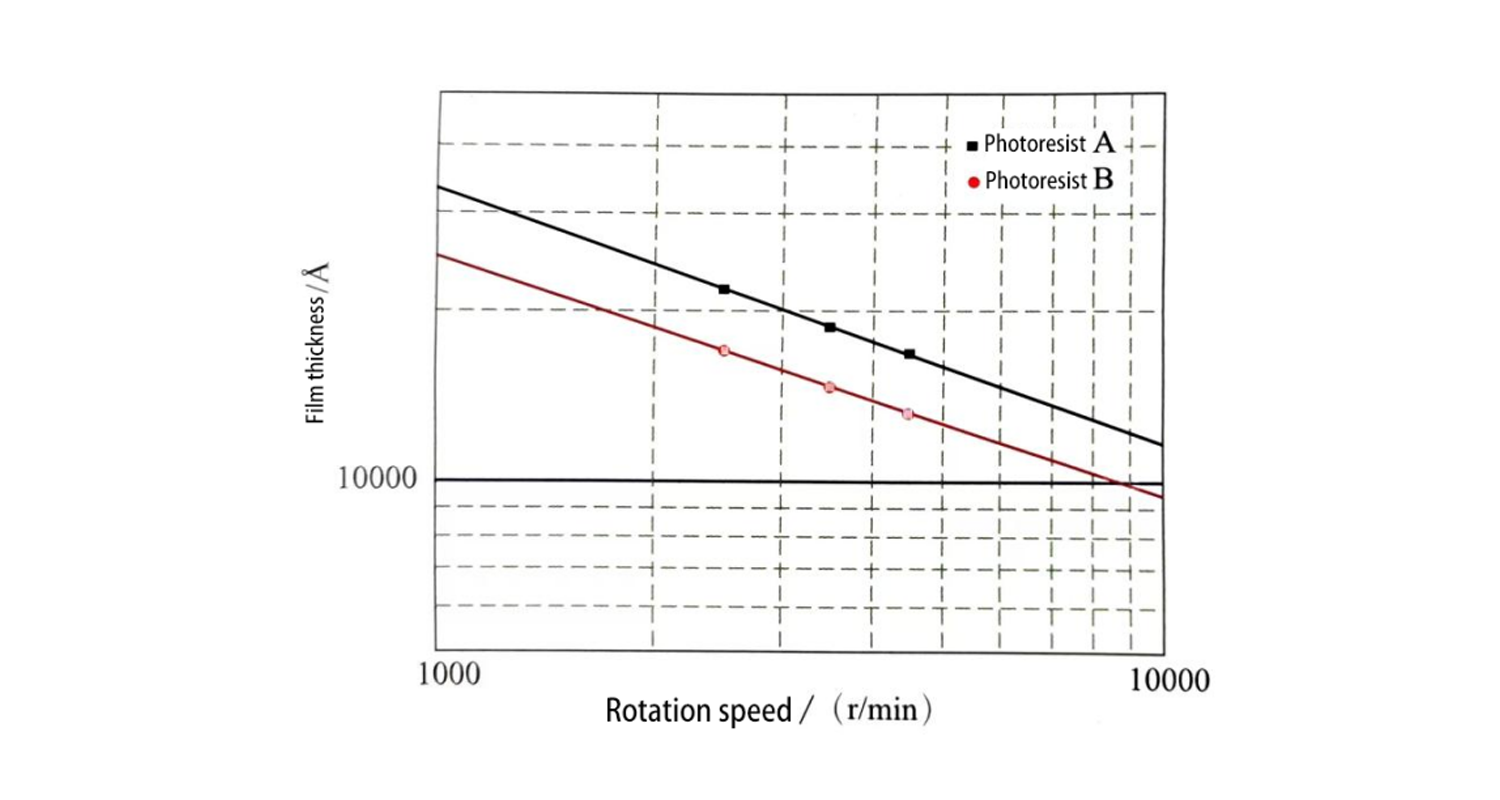

Kodayake kaurin fim ɗin yana ƙaddara ta babban saurin juyawa, yana da alaƙa da yanayin zafin jiki, zafi, danko na hoto da nau'in hoto. Ana nuna kwatancen nau'ikan nau'ikan nau'ikan lanƙwasa mai ɗaukar hoto a hoto na 1.

Hoto 1: Kwatanta nau'ikan nau'ikan nau'ikan lanƙwasa na hoto

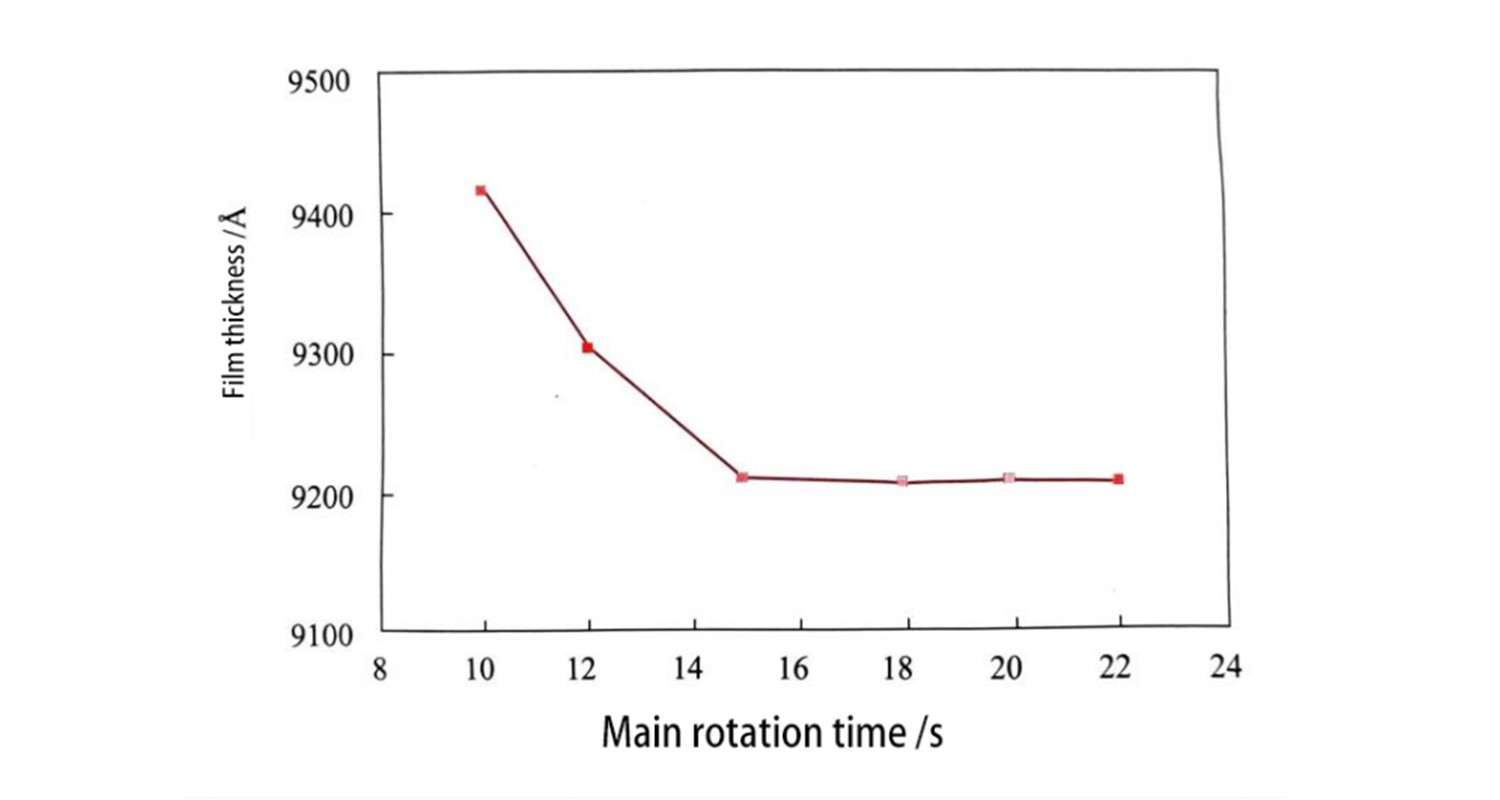

Tasirin babban lokacin juyawa

Mafi guntu babban lokacin juyawa, mafi girman kauri na fim. Lokacin da babban lokacin juyawa ya karu, fim ɗin ya zama mafi ƙaranci. Lokacin da ya wuce 20s, kaurin fim ɗin ya kasance kusan ba canzawa. Don haka, galibi ana zaɓar babban lokacin juyawa don zama fiye da daƙiƙa 20. Dangantakar da ke tsakanin babban lokacin jujjuyawa da kaurin fim ana nuna shi a hoto na 2.

Hoto 2: Dangantaka tsakanin babban lokacin juyawa da kauri na fim

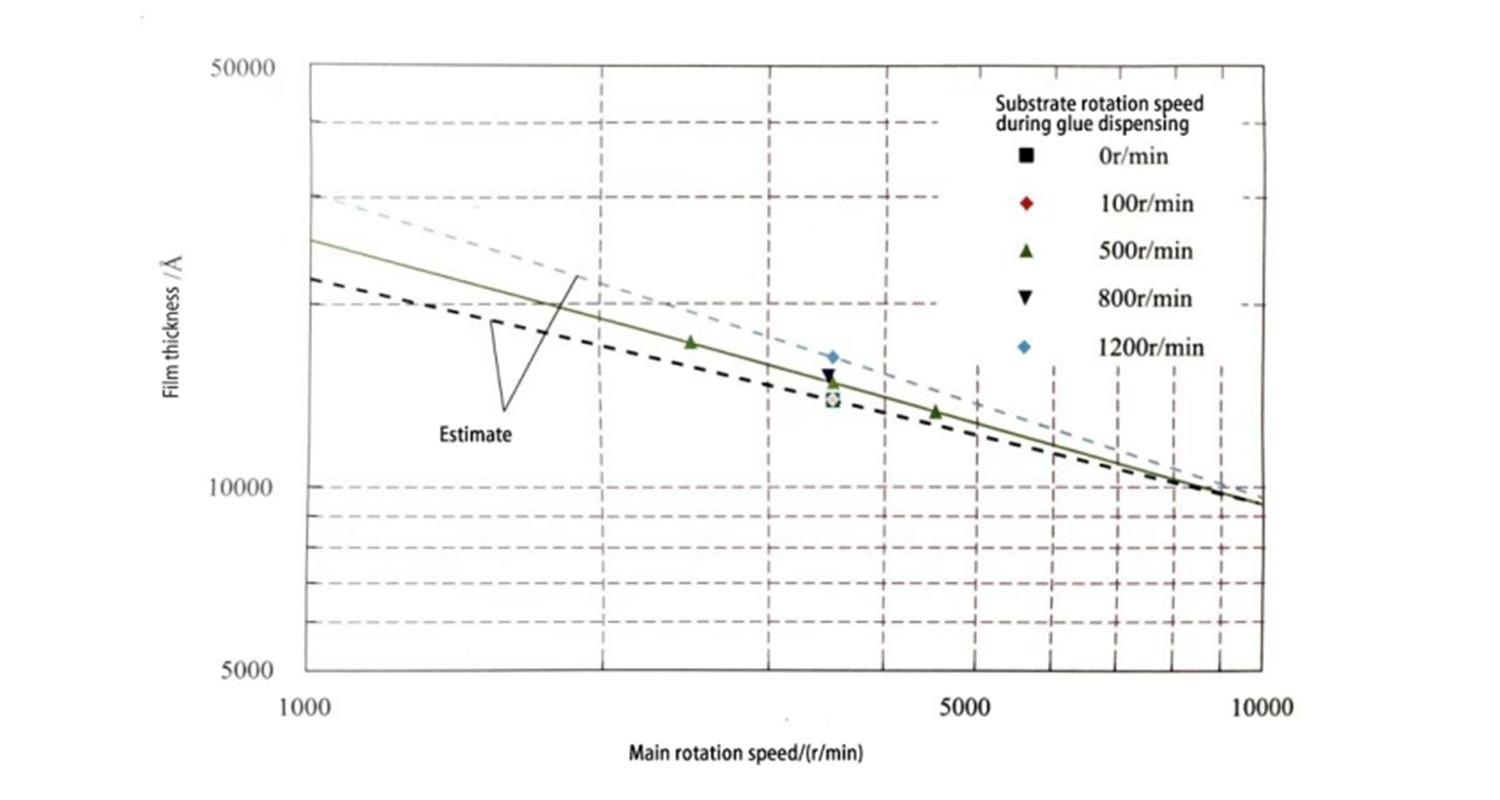

Lokacin da photoresist aka dripped a kan substrate, ko da na gaba babban juyi gudun ne guda, juyi gudun substrate a lokacin dripping zai shafi karshe fim kauri. Kaurin fim ɗin hoto yana ƙaruwa tare da haɓaka saurin jujjuyawar juzu'i a lokacin dripping, wanda shine saboda tasirin ƙamshi mai ƙanƙara lokacin da aka buɗe hoto bayan dripping. Hoto na 3 yana nuna alaƙar da ke tsakanin kauri na fim da babban saurin juyawa a cikin saurin jujjuyawar juzu'i daban-daban yayin dripping photoresist. Ana iya gani daga adadi cewa tare da haɓaka saurin juyawa na ɗigon ruwa, kauri na fim yana canzawa da sauri, kuma bambanci ya fi bayyana a cikin yanki tare da ƙananan saurin juyawa.

Hoto 3: Dangantaka tsakanin kauri na fim da babban saurin juyawa a saurin jujjuyawar juzu'i daban-daban yayin rarrabawar hoto.

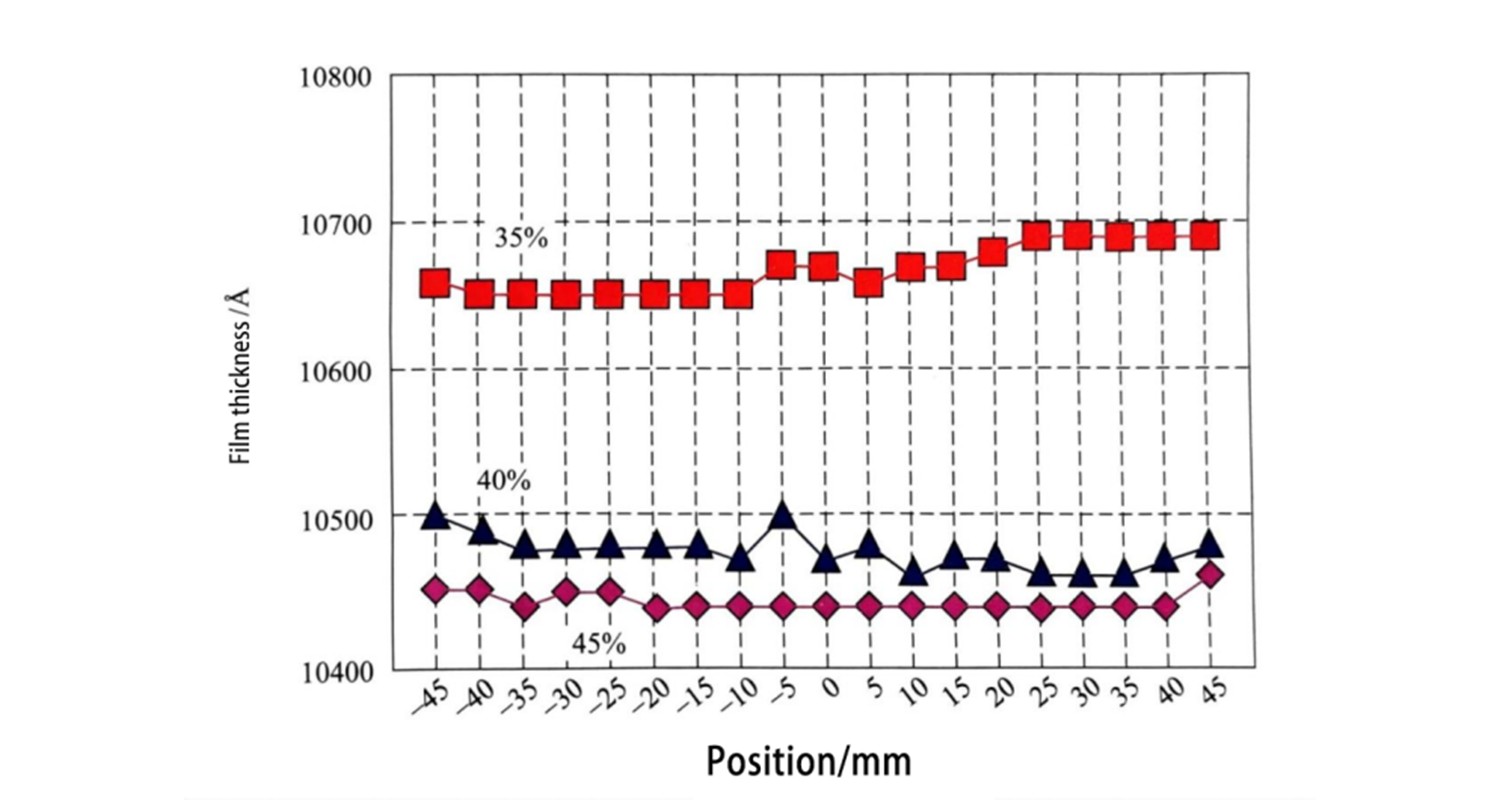

Sakamakon zafi a lokacin sutura

Lokacin da zafi ya ragu, kauri na fim yana ƙaruwa, saboda raguwa a cikin zafi yana inganta ƙazantar da ƙarfi. Duk da haka, rarraba kauri na fim ba ya canzawa sosai. Hoto na 4 yana nuna alaƙa tsakanin zafi da rarraba kauri na fim yayin sutura.

Hoto 4: Dangantaka tsakanin zafi da rarraba kauri na fim yayin sutura

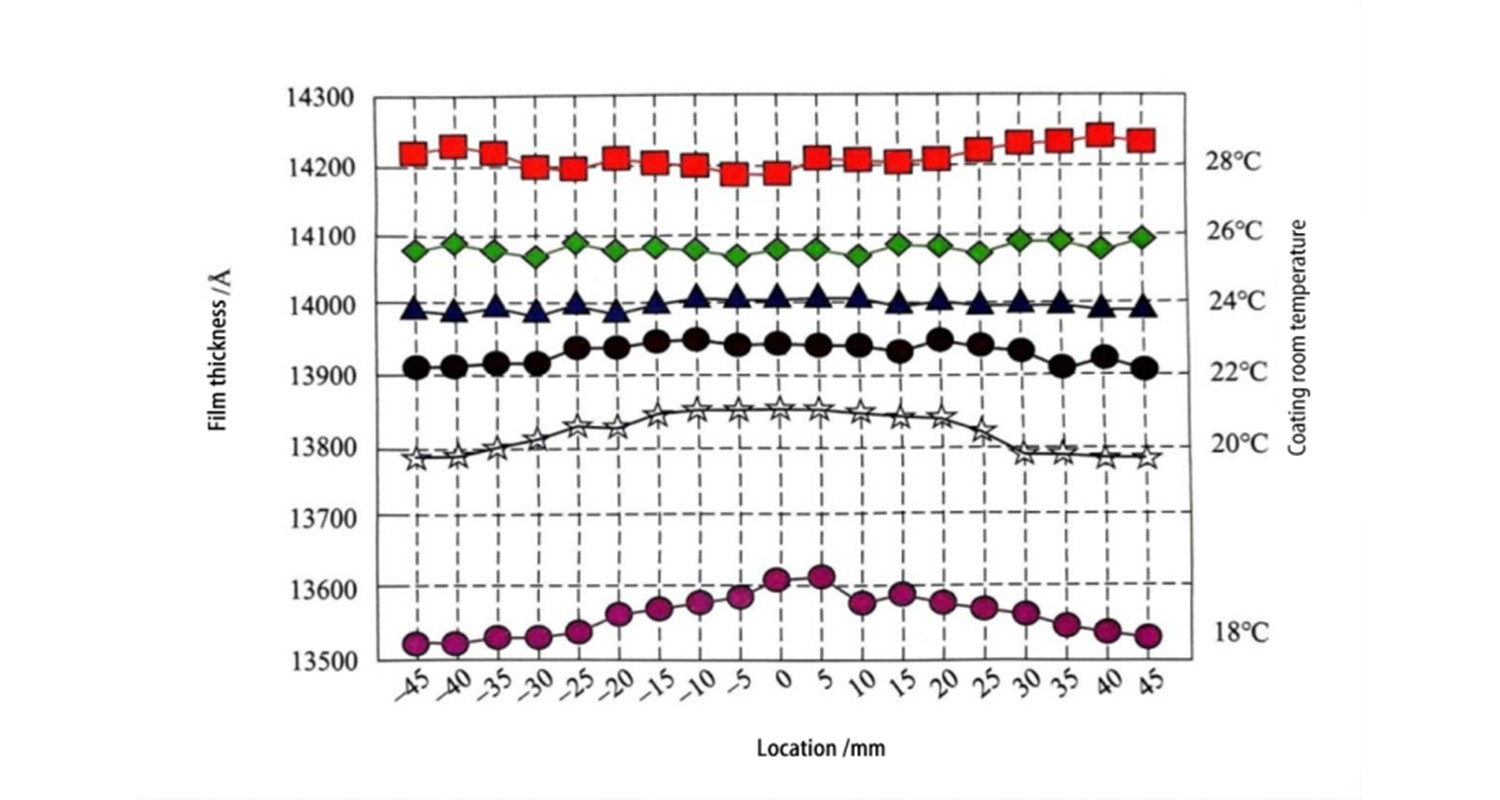

Tasirin zafin jiki yayin rufewa

Lokacin da zafin jiki na cikin gida ya tashi, kauri na fim yana ƙaruwa. Ana iya gani daga Hoto na 5 cewa kaurin fim ɗin photoresist ya canza daga convex zuwa concave. Lanƙwan da ke cikin wannan adadi ya kuma nuna cewa ana samun daidaito mafi girma lokacin da yanayin cikin gida ya kai 26°C kuma zafin zafin jiki ya kai 21°C.

Hoto 5: Dangantaka tsakanin zafin jiki da rarraba kauri na fim yayin sutura

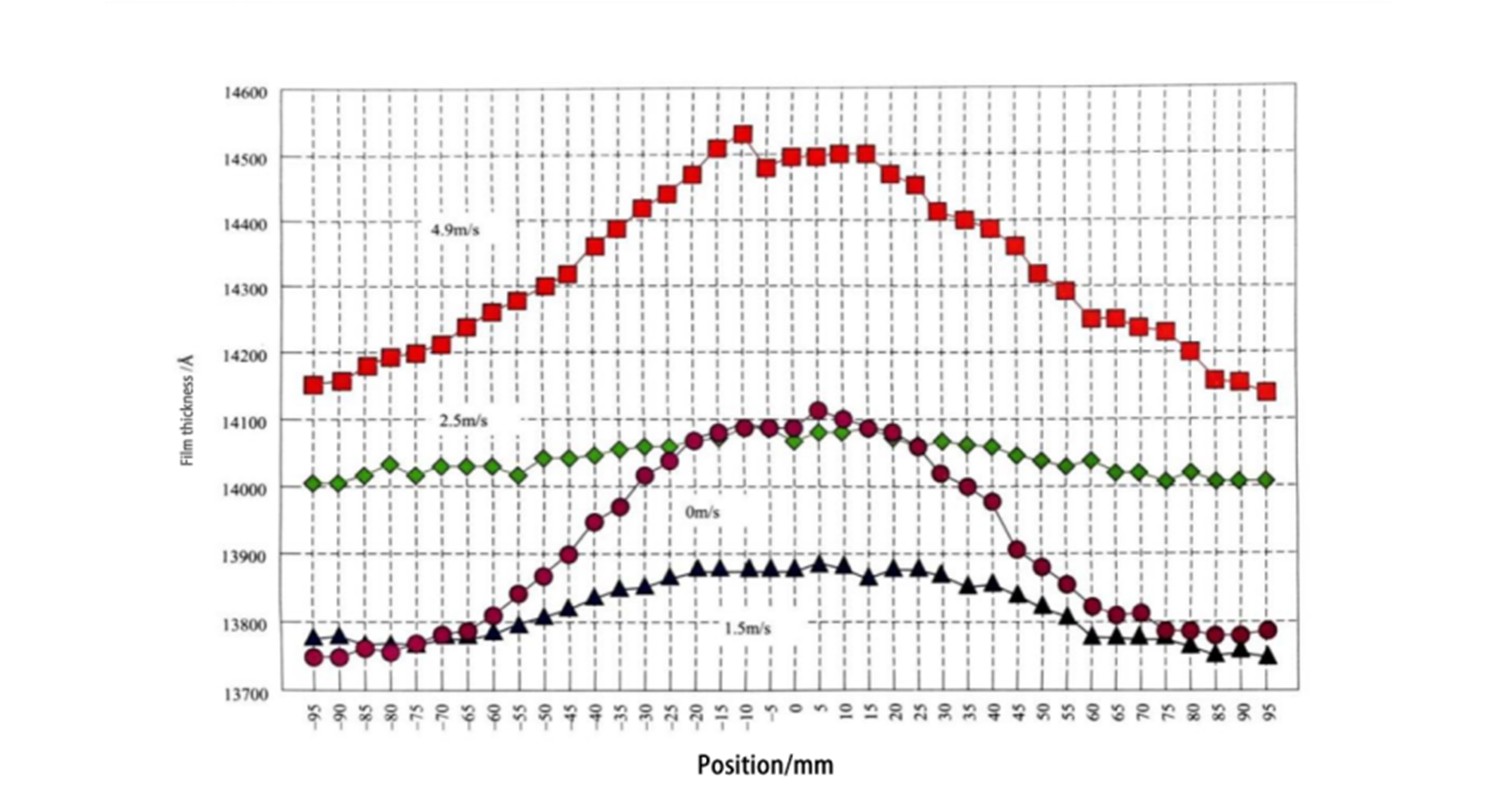

Tasirin saurin shayewa yayin rufewa

Hoto na 6 yana nuna alaƙar da ke tsakanin saurin shaye-shaye da rarraba kauri na fim. Idan babu shaye-shaye, yana nuna cewa tsakiyar wafer yana ƙoƙarin yin kauri. Ƙara saurin shaye-shaye zai inganta daidaituwa, amma idan an ƙara shi da yawa, daidaito zai ragu. Ana iya ganin cewa akwai ƙimar mafi kyau ga saurin shayewa.

Hoto 6: Dangantaka tsakanin saurin shayewa da rarraba kauri na fim

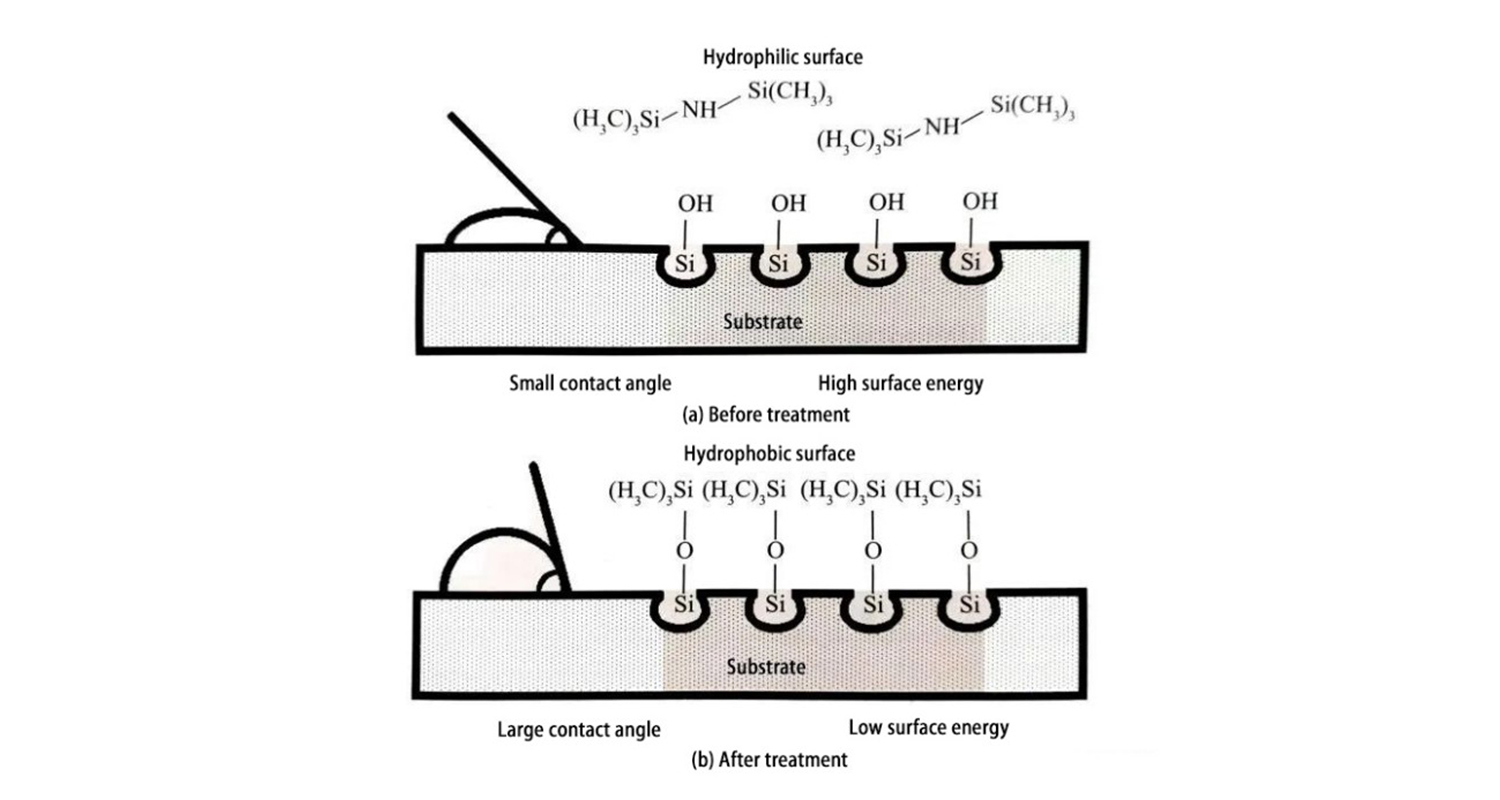

HMDS magani

Domin sanya photoresist ya zama mai suturta, wafer ɗin yana buƙatar a yi masa magani da hexamethyldisilazane (HMDS). Musamman lokacin da aka haɗa danshi zuwa saman fim din Si oxide, an kafa silanol, wanda ya rage mannewa na photoresist. Domin cire danshi da rugujewar silanol, ana yawan zafi da wafer zuwa 100-120°C, kuma an gabatar da hazo HMDS don haifar da wani sinadari. Ana nuna tsarin amsawa a cikin Hoto 7. Ta hanyar jiyya na HMDS, farfajiyar hydrophilic tare da ƙaramin kusurwar lamba ya zama saman hydrophobic tare da babban kusurwar lamba. Dumama wafer na iya samun mannewa mafi girma na photoresist.

Hoto 7: HMDS tsarin amsawa

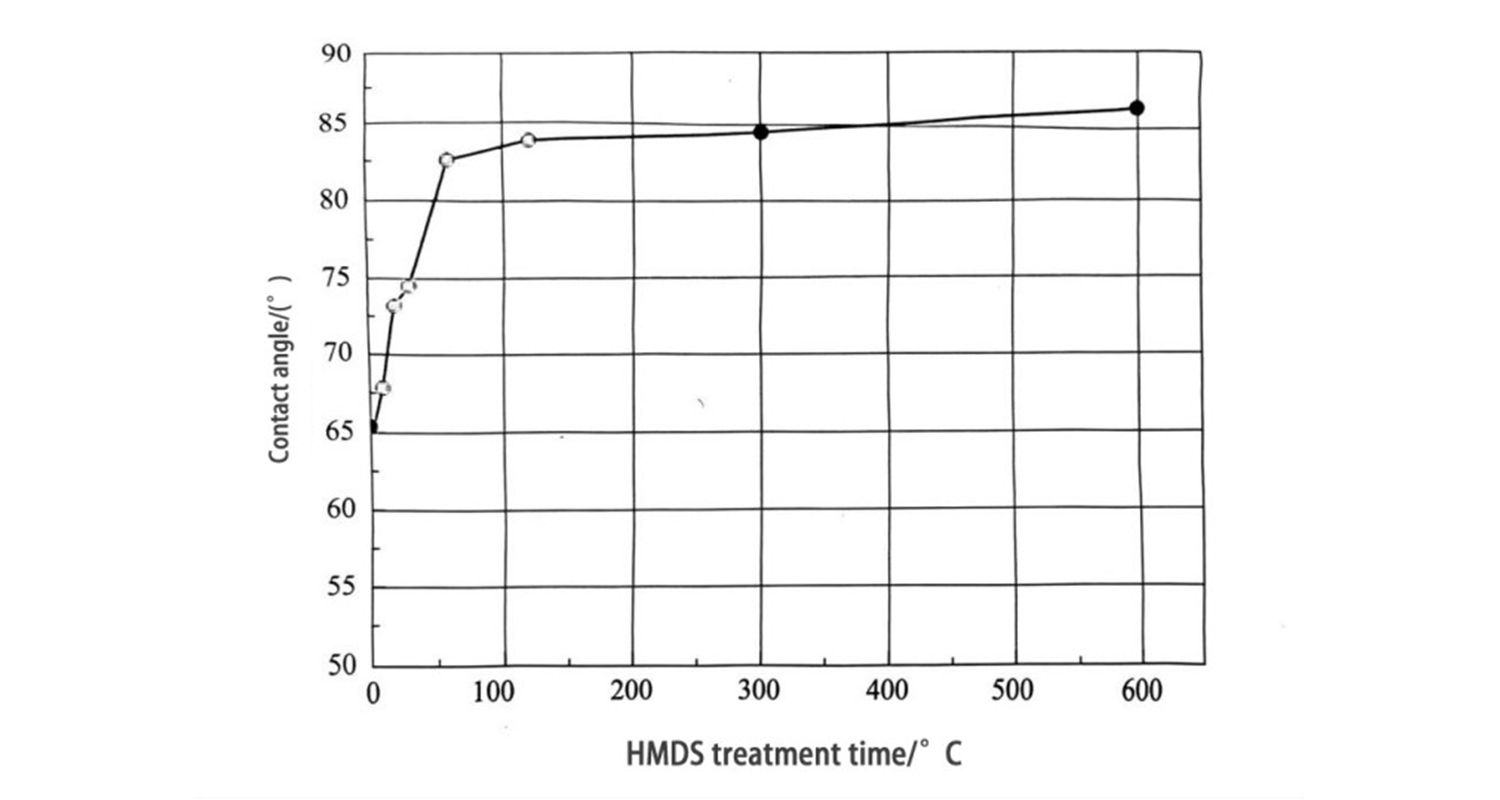

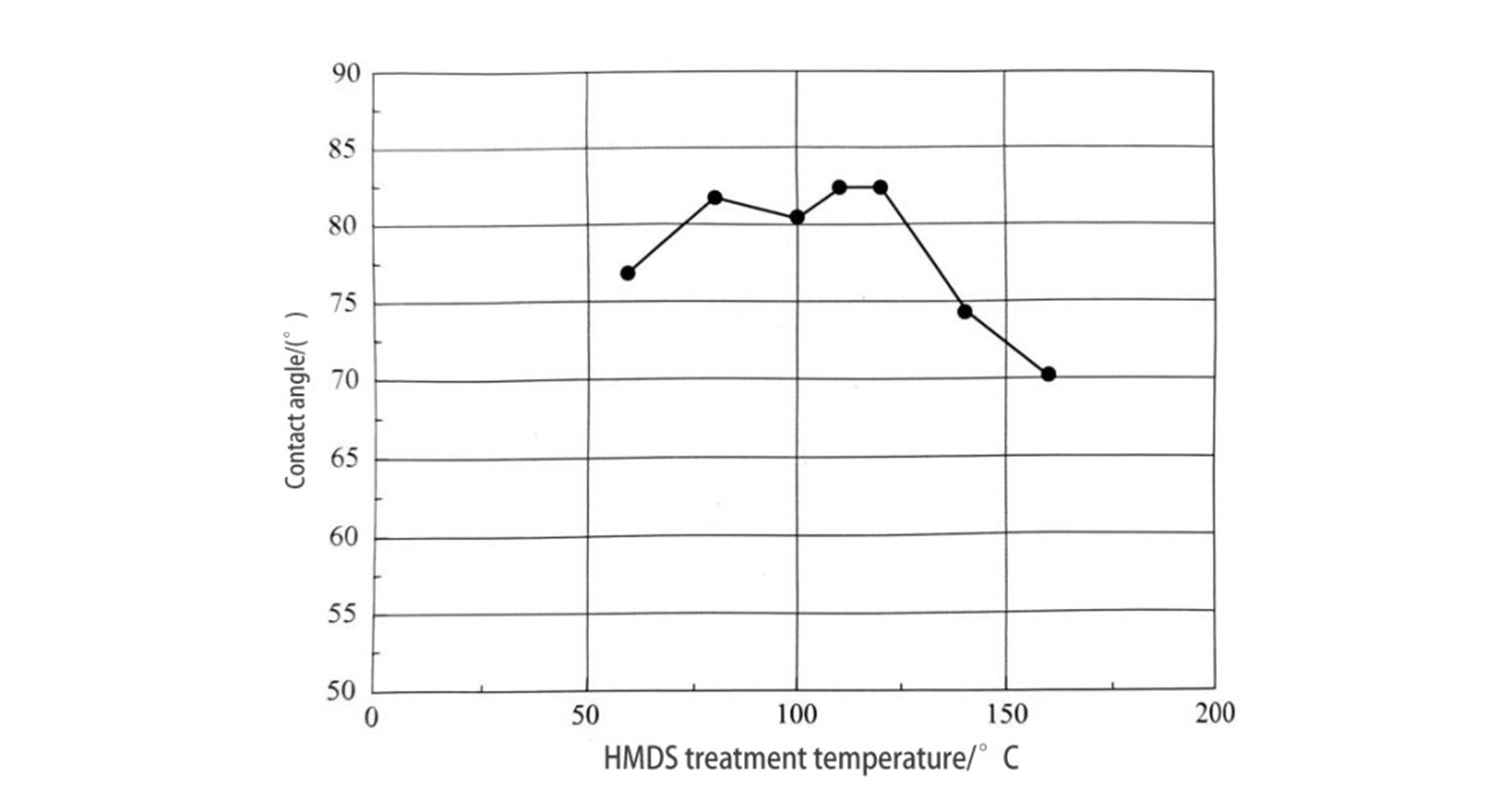

Ana iya lura da tasirin jiyya na HMDS ta hanyar auna kusurwar lamba. Hoto 8 yana nuna alaƙa tsakanin lokacin jiyya na HMDS da kusurwar lamba (zazzabi na jiyya 110 ° C). Substrate shine Si, lokacin jiyya na HMDS ya fi 1min, kusurwar lamba ya fi 80 °, kuma tasirin jiyya ya tabbata. Hoto na 9 yana nuna alaƙa tsakanin zafin jiyya na HMDS da kusurwar lamba (lokacin jiyya 60s). Lokacin da zafin jiki ya wuce 120 ℃, kusurwar lamba yana raguwa, yana nuna cewa HMDS yana rubewa saboda zafi. Saboda haka, yawanci ana yin maganin HMDS a 100-110 ℃.

Hoto 8: Dangantaka tsakanin lokacin jiyya na HMDS

da kusurwar lamba (magungunan zazzabi 110 ℃)

Hoto 9: Dangantaka tsakanin zafin jiyya na HMDS da kusurwar lamba (lokacin jiyya 60s)

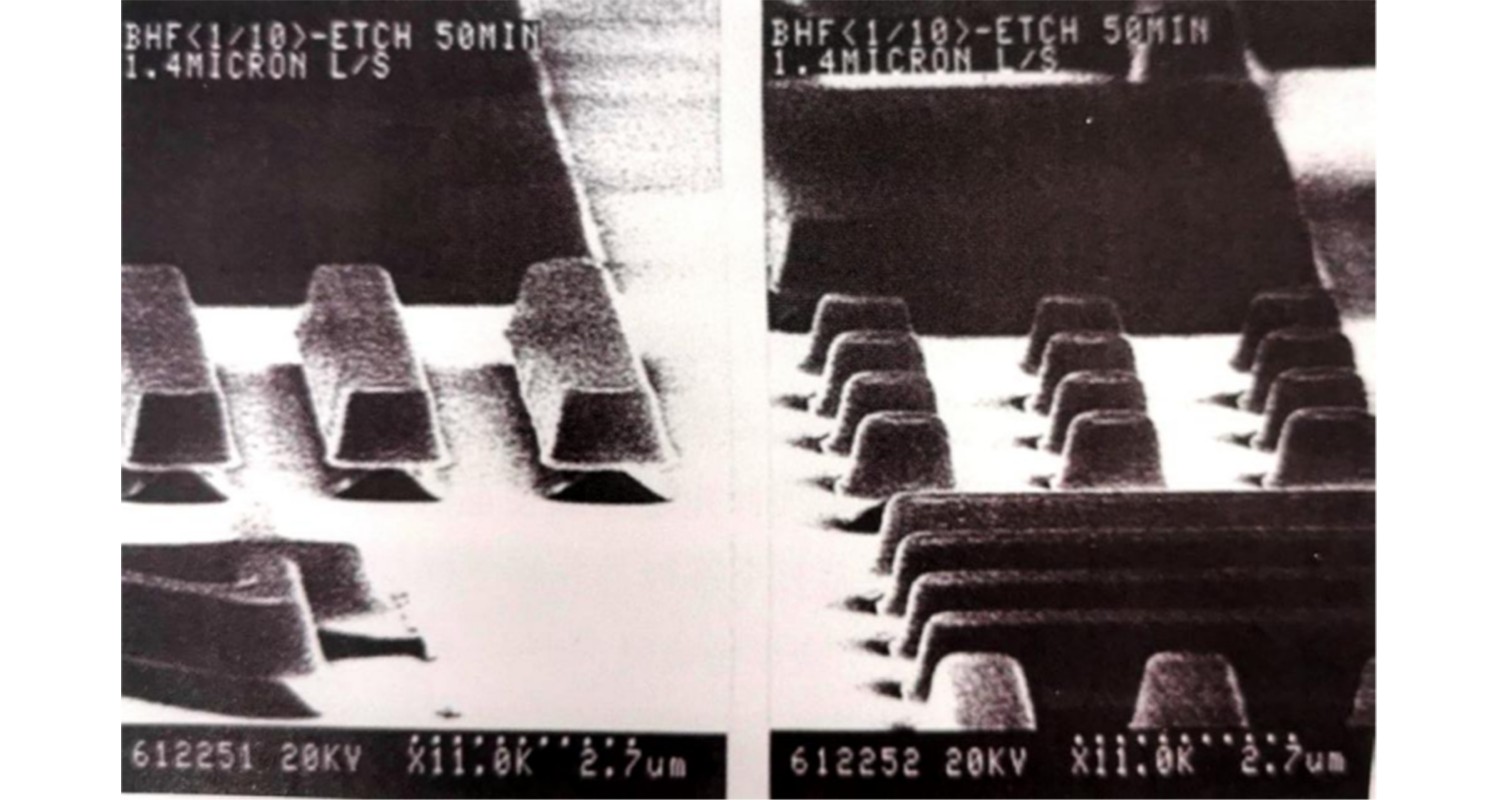

Ana yin jiyya na HMDS akan ma'aunin siliki tare da fim ɗin oxide don samar da ƙirar hoto. Fim ɗin oxide kuma an haɗa shi da hydrofluoric acid tare da ƙara da buffer, kuma an gano cewa bayan jiyya na HMDS, za a iya kiyaye tsarin photoresist daga faɗuwa. Hoto na 10 yana nuna tasirin jiyya na HMDS (girman ƙirar shine 1um).

Hoto 10: Tasirin jiyya na HMDS (girman tsari shine 1um)

Ana yin burodi

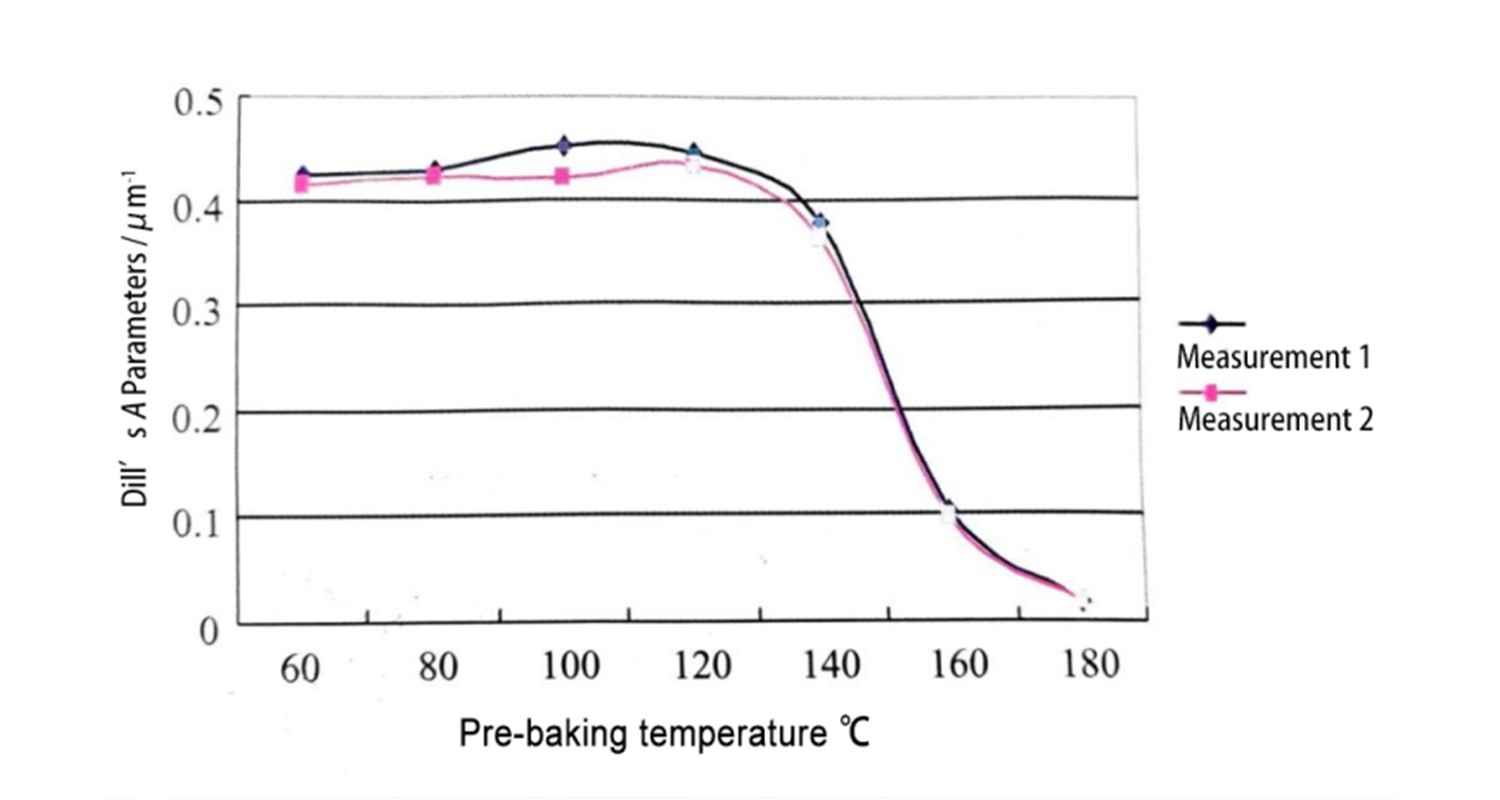

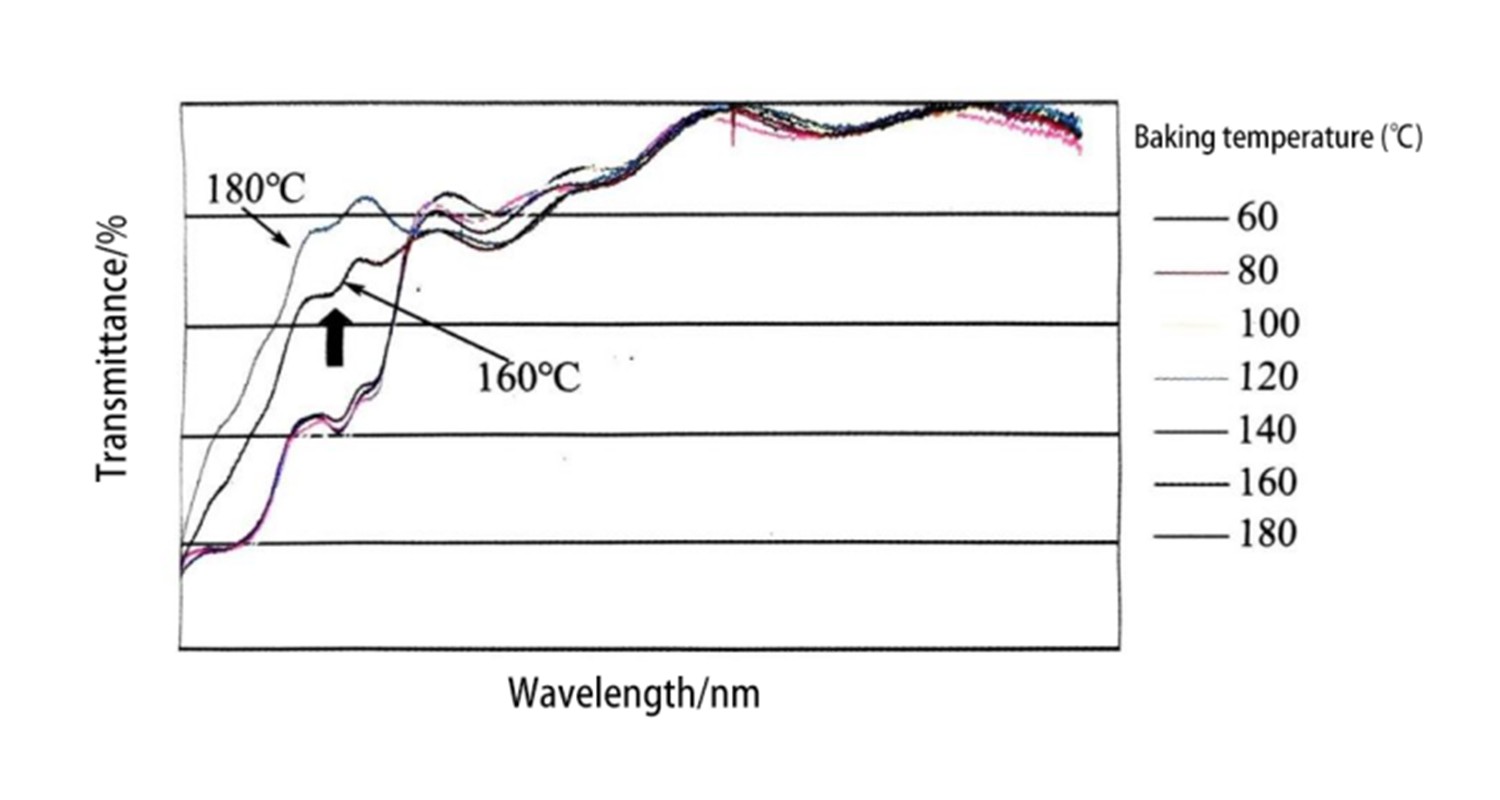

A daidai wannan saurin juyawa, mafi girma da zafin jiki na prebaking, ƙananan kauri na fim, wanda ke nuna cewa mafi girma da zafin jiki na prebaking, mafi yawan sauran ƙarfi yana ƙafewa, yana haifar da kauri na fim. Hoto na 11 yana nuna alakar da ke tsakanin zafin da ake yin burodi da kuma ma'aunin Dill A. Ma'aunin A yana nuna ƙaddamar da wakili mai ɗaukar hoto. Kamar yadda ake iya gani daga adadi, lokacin da zafin zafin da aka yi kafin yin burodi ya tashi sama da 140 ° C, ma'aunin A yana raguwa, yana nuna cewa mai ɗaukar hoto yana bazuwa a yanayin zafi sama da wannan. Hoto na 12 yana nuna saurin watsawa a yanayin zafi daban-daban kafin yin burodi. A 160 ° C da 180 ° C, ana iya ganin haɓakar watsawa a cikin kewayon tsayin 300-500nm. Wannan yana tabbatar da cewa ana gasa wakili mai ɗaukar hoto kuma yana bazu a yanayin zafi mai yawa. Yanayin zafin jiki na kafin yin burodi yana da ƙimar mafi kyau, wanda aka ƙaddara ta halayen haske da hankali.

Hoto 11: Dangantaka tsakanin zafin da aka riga aka yi burodi da siga na Dill A

(ƙimar aunawa na OFPR-800/2)

Hoto 12: Canja wurin kallo a yanayin zafi daban-daban kafin yin burodi

(OFPR-800, kauri na fim 1um)

A takaice dai, hanyar suturar jujjuyawar tana da fa'idodi na musamman irin su daidaitaccen iko na kauri na fim, ƙimar farashi mai yawa, yanayin tsari mai sauƙi, da aiki mai sauƙi, don haka yana da tasiri mai mahimmanci wajen rage gurɓataccen gurɓataccen iska, adana makamashi, da haɓaka ƙimar farashi. A cikin 'yan shekarun nan, suturar jujjuyawar tana ƙara samun kulawa, kuma aikace-aikacen sa a hankali ya bazu zuwa fannoni daban-daban.

Lokacin aikawa: Nuwamba-27-2024