A cikin tsarin masana'antar semiconductor,etchingfasaha wani tsari ne mai mahimmanci wanda ake amfani dashi don cire kayan da ba'a so daidai akan ma'aunin don samar da tsarin da'ira mai rikitarwa. Wannan labarin zai gabatar da manyan fasahohin etching guda biyu daki-daki - capacitively coupled plasma etching (CCP) da inductively coupled plasma etching.ICP), da kuma bincika aikace-aikacen su a cikin etching kayan daban-daban.

Capacitively hade da plasma etching (CCP)

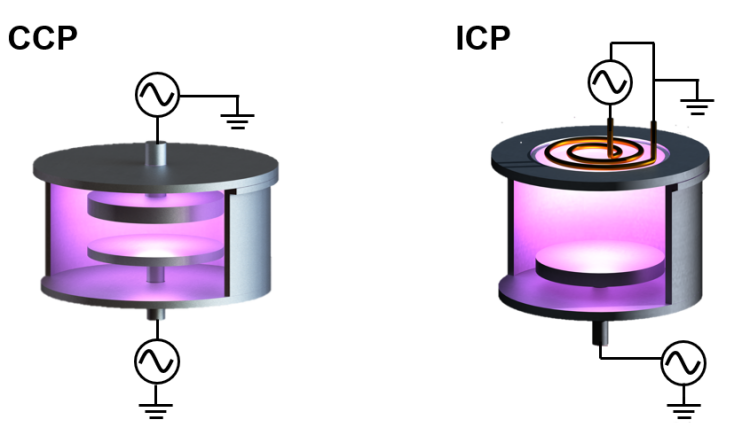

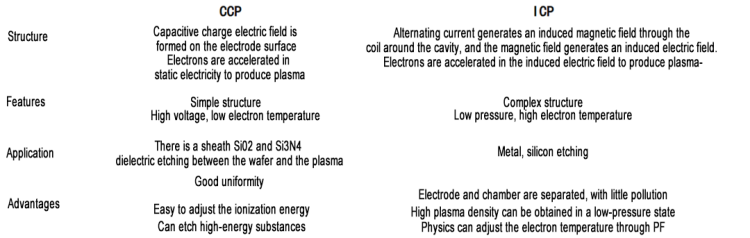

Ana samun ƙarfin haɗe-haɗe na plasma etching (CCP) ta hanyar yin amfani da wutar lantarki na RF zuwa na'urorin lantarki guda biyu masu kama da juna ta hanyar ma'ajin da na'urar toshewar DC. Na'urorin lantarki guda biyu da plasma tare suna samar da capacitor daidai. A cikin wannan tsari, ƙarfin wutar lantarki na RF yana samar da kwasfa mai ƙarfi kusa da lantarki, kuma iyakacin kwafin yana canzawa tare da saurin oscillation na ƙarfin lantarki. Lokacin da electrons suka isa wannan kumfa mai saurin canzawa, suna nunawa kuma suna samun kuzari, wanda hakan ke haifar da rabuwa ko ionization na kwayoyin gas don samar da plasma. CCP etching yawanci ana amfani da kayan da ke da ƙarfin haɗin sinadarai mafi girma, kamar dielectrics, amma saboda ƙarancin etching ɗin sa, ya dace da aikace-aikacen da ke buƙatar kulawa mai kyau.

Plasma etching a cikin inductively (ICP)

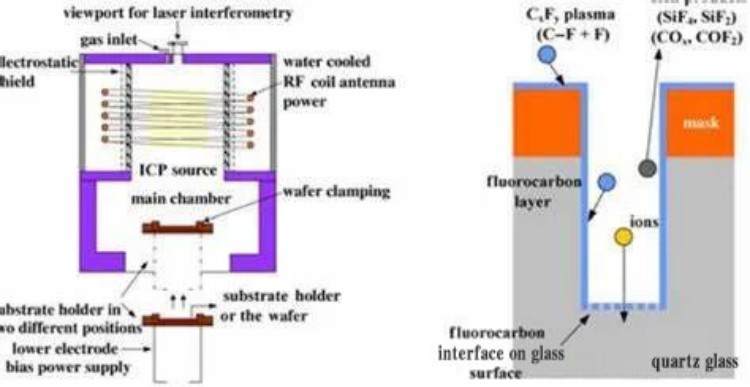

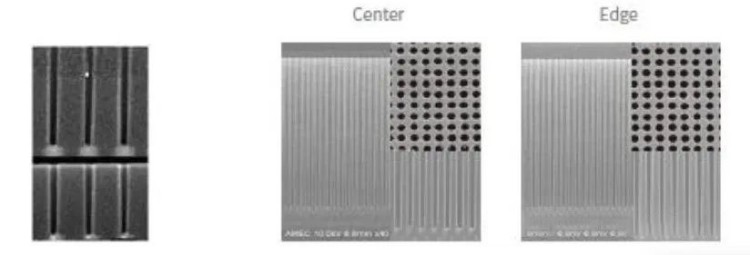

plasma haɗe-haɗe da inductivelyetching(ICP) ya dogara ne akan ƙa'idar cewa madaidaicin halin yanzu yana wucewa ta cikin coil don samar da filin maganadisu da aka jawo. A karkashin aikin wannan filin maganadisu, electrons a cikin dakin amsawa suna hanzari kuma suna ci gaba da sauri a cikin wutar lantarki da aka haifar, a ƙarshe suna yin karo da kwayoyin cutar da iskar gas, wanda ya sa kwayoyin su rabu ko ionize su zama plasma. Wannan hanya na iya samar da babban adadin ionization kuma ya ba da damar daidaita yawan ƙwayar plasma da makamashin bombardment da kansa, wanda ya saICP ta ciresosai dace da etching kayan tare da low sinadaran bond makamashi, kamar silicon da karfe. Bugu da kari, fasahar ICP kuma tana samar da ingantacciyar daidaituwa da ƙimar etching.

1. Karfe etching

Karfe etching ne yafi amfani da aiki na interconnects da Multi-Layer karfe wayoyi. Bukatunsa sun haɗa da: babban etching rate, high selectivity (mafi girma 4: 1 ga mashin Layer kuma mafi girma fiye da 20:1 don interlayer dielectric), high etching uniformity, mai kyau m girma iko, babu plasma lalacewa, m ragowar gurɓata, da kuma babu lalata ga karfe. Ƙarfe na yawanci yana amfani da kayan aikin etching na plasma tare da haɗin gwiwa.

•Aluminum etching: Aluminum shine mafi mahimmancin kayan waya a cikin matakan tsakiya da baya na masana'antar guntu, tare da fa'idodin ƙarancin juriya, sauƙi mai sauƙi da etching. Aluminum etching yawanci yana amfani da plasma da iskar chloride ke samarwa (kamar Cl2). Aluminum yana amsawa tare da chlorine don samar da aluminium chloride maras tabbas (AlCl3). Bugu da ƙari, ana iya ƙara wasu halides irin su SiCl4, BCl3, BBr3, CCl4, CHF3, da dai sauransu don cire oxide Layer a kan aluminum surface don tabbatar da al'ada etching.

• Tungsten etching: A cikin tsarin haɗin haɗin waya mai nau'i-nau'i da yawa, tungsten shine babban ƙarfe da ake amfani da shi don haɗin sashin tsakiya na guntu. Ana iya amfani da gas na tushen Fluorine ko chlorine don haɓaka tungsten ƙarfe, amma gas na tushen fluorine yana da ƙarancin zaɓi don silicon oxide, yayin da gas na tushen chlorine (kamar CCl4) yana da zaɓi mafi kyau. Nitrogen yawanci ana ƙara shi zuwa iskar gas don samun babban zaɓin manne mai etching, kuma ana ƙara iskar oxygen don rage ajiyar carbon. Etching tungsten tare da tushen sinadarin chlorine na iya cimma etching anisotropic da babban zaɓi. Gas da ake amfani da su wajen bushe bushewar tungsten sun fi SF6, Ar da O2, daga cikinsu SF6 za a iya bazuwa a cikin jini don samar da atom na fluorine da tungsten don maganin sinadarai don samar da fluoride.

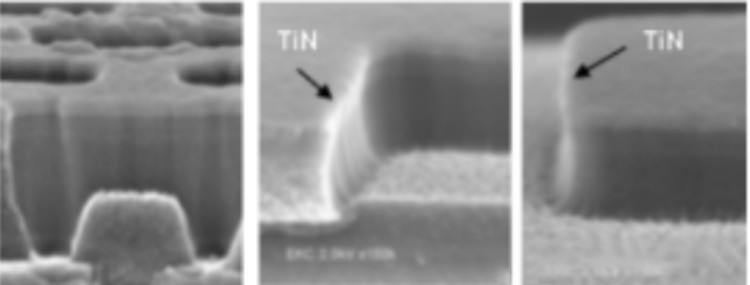

• Titanium nitride etching: Titanium nitride, a matsayin abin rufe fuska mai wuya, ya maye gurbin siliki nitride na gargajiya ko abin rufe fuska na oxide a cikin tsarin damascene dual. Titanium nitride etching ana amfani dashi galibi a cikin aikin buɗe abin rufe fuska mai wuya, kuma babban samfurin amsawa shine TiCl4. Zaɓin zaɓi tsakanin abin rufe fuska na al'ada da ƙananan k dielectric Layer ba shi da girma, wanda zai haifar da bayyanar da siffar arc a saman ƙananan k-dielectric Layer da kuma fadada nisa na tsagi bayan etching. Tazarar da ke tsakanin layukan ƙarfe da aka ajiye ya yi ƙanƙanta sosai, wanda ke da yuwuwar gadar ɗigogi ko rushewar kai tsaye.

2. Insulator etching

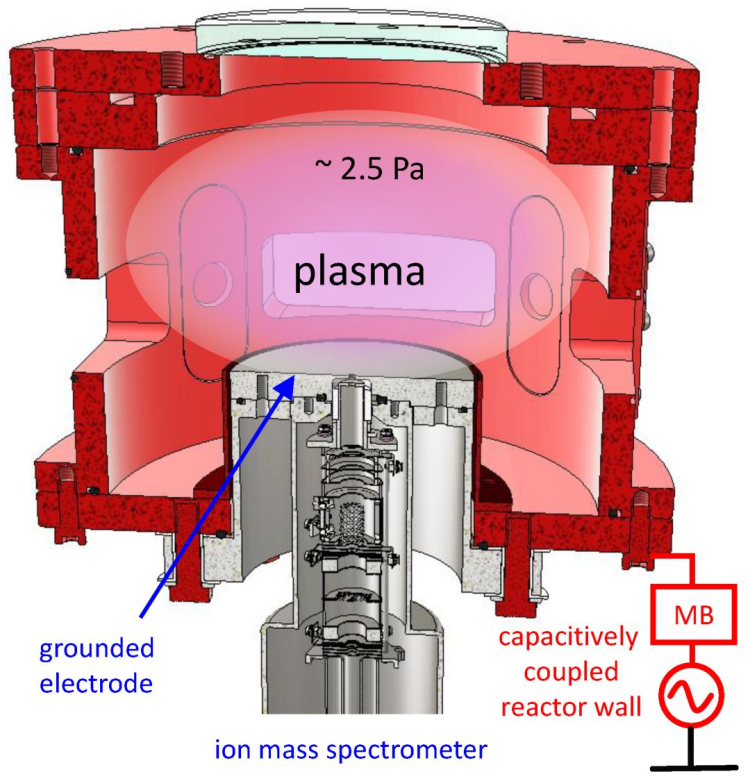

Abubuwan da ake yin insulator galibi kayan aikin dielectric ne kamar silicon dioxide ko silicon nitride, waɗanda ake amfani da su sosai don ƙirƙirar ramukan lamba da ramukan tashoshi don haɗa yadudduka daban-daban. Dielectric etching yawanci yana amfani da echer bisa ka'idar capacitively hade da etching plasma.

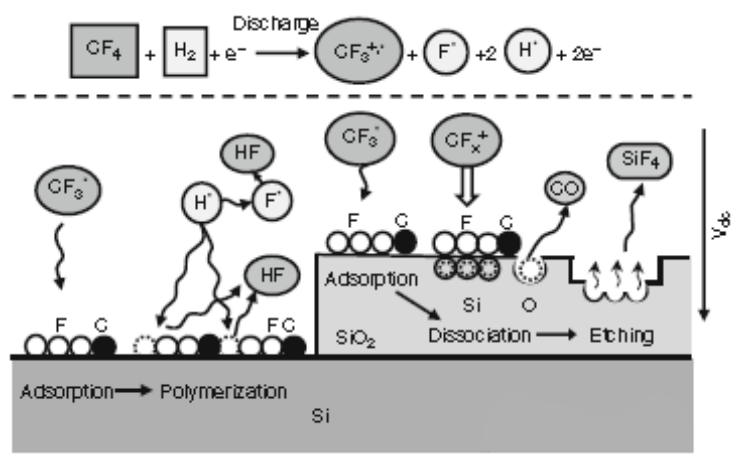

• Fim ɗin filasta na silicon dioxide: Fim ɗin Silicon dioxide yawanci ana haɗe shi ta amfani da iskar gas mai ɗauke da fluorine, kamar CF4, CHF3, C2F6, SF6 da C3F8. Carbon da ke cikin etching gas zai iya amsawa tare da iskar oxygen a cikin Layer oxide don samar da samfuran CO da CO2, ta haka ne ke cire iskar oxygen a cikin Layer oxide. CF4 shine mafi yawan amfani da iskar gas. Lokacin da CF4 ta yi karo da electrons masu ƙarfi, ana samar da ions daban-daban, radicals, atom da free radicals. radicals masu kyauta na fluorine na iya amsawa ta hanyar sinadarai tare da SiO2 da Si don samar da tetrafluoride silicon mai canzawa (SiF4).

• Plasma etching na silicon nitride fim: Silicon nitride fim za a iya etching ta amfani da plasma etching tare da CF4 ko CF4 gauraye gas (tare da O2, SF6 da NF3). Don fim ɗin Si3N4, lokacin da ake amfani da plasma na CF4-O2 ko wani plasma na gas mai ɗauke da F atom don etching, ƙimar siliki na nitride na iya kaiwa 1200Å/min, kuma zaɓin etching na iya zama kamar 20: 1. Babban samfurin shine silicon tetrafluoride (SiF4) maras tabbas wanda ke da sauƙin cirewa.

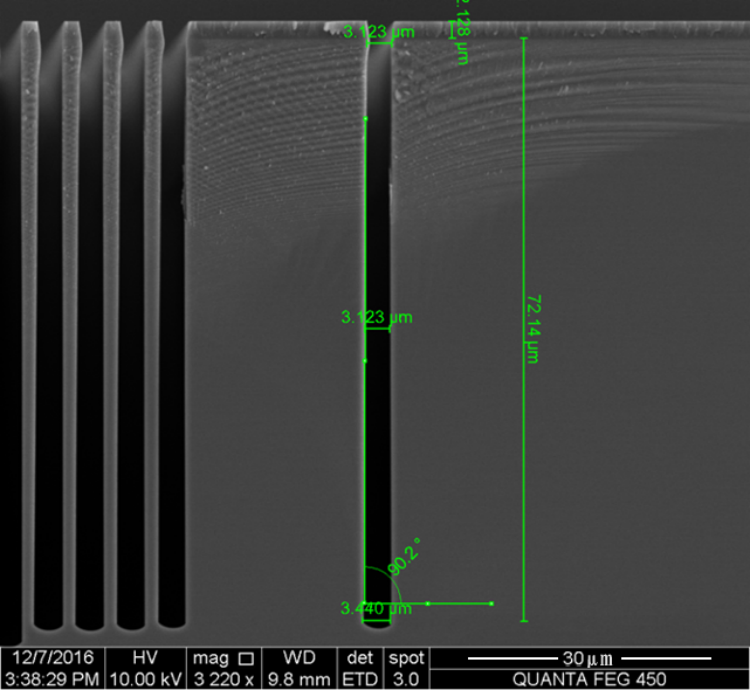

3. Single crystal silicon etching

Single crystal etching silicon etching ne yafi amfani don samar da m ramuka ware (STI). Wannan tsari yawanci ya haɗa da tsarin ci gaba da babban tsarin etching. Tsarin ci gaba yana amfani da SiF4 da NF gas don cire oxide Layer a saman silin siliki guda ɗaya ta hanyar fashewar ion mai ƙarfi da aikin sinadarai na abubuwan fluorine; Babban etching yana amfani da hydrogen bromide (HBr) a matsayin babban etching. Abubuwan radicals na bromine da HBr suka rushe a cikin yanayin plasma suna amsawa da silicon don samar da silicon tetrabromide mai canzawa (SiBr4), don haka cire silicon. Single crystal etching silicone yawanci yana amfani da na'urar etching na plasma da aka haɗe.

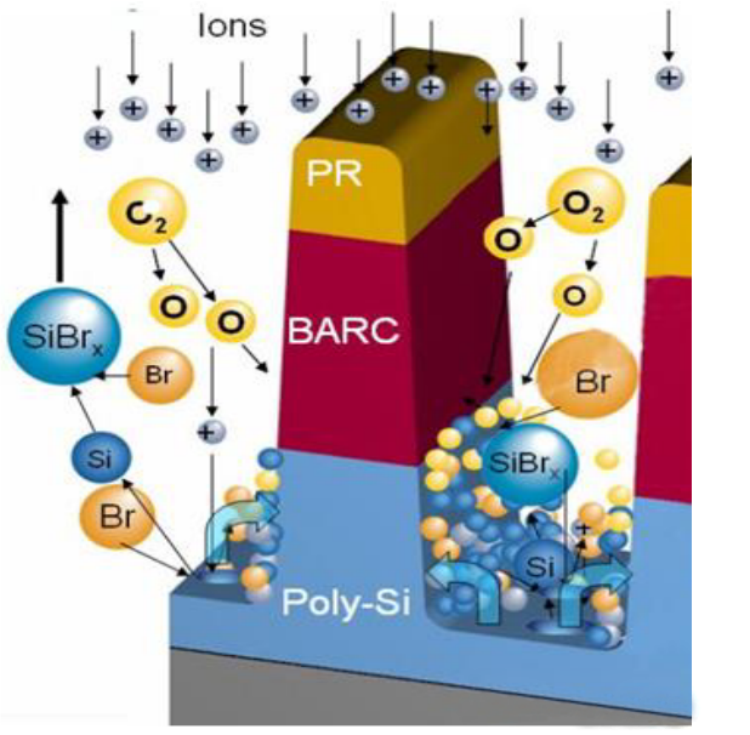

4. Polysilicon Etching

Polysilicon etching yana ɗaya daga cikin mahimman hanyoyin da ke ƙayyade girman kofa na transistor, kuma girman ƙofar yana rinjayar aikin haɗaɗɗun da'irori. Polysilicon etching yana buƙatar ƙimar zaɓi mai kyau. Ana amfani da iskar halogen irin su chlorine (Cl2) don cimma etching anisotropic, kuma suna da ƙimar zaɓi mai kyau (har zuwa 10: 1). Gas na tushen Bromine kamar hydrogen bromide (HBr) na iya samun ƙimar zaɓi mafi girma (har zuwa 100: 1). Cakuda HBr tare da chlorine da oxygen na iya ƙara yawan etching. Ana ajiye samfuran halayen halogen gas da silicon akan bangon gefe don taka rawar kariya. Polysilicon etching yawanci yana amfani da na'urar etching na plasma da aka haɗe.

Ko yana iya haɗawa da etching na plasma mai ƙarfi ko kuma haɗaɗɗen ƙwayar ƙwayar cuta, kowanne yana da fa'idodinsa na musamman da halayen fasaha. Zaɓin fasahar etching mai dacewa ba zai iya inganta haɓakar samarwa kawai ba, amma kuma tabbatar da yawan amfanin ƙasa na ƙarshe.

Lokacin aikawa: Nuwamba-12-2024