A cikin masana'anta na semiconductor, akwai wata dabara da ake kira "etching" a lokacin sarrafa kayan aiki ko fim na bakin ciki da aka kafa akan ma'auni. Haɓaka fasahar etching ya taka rawa wajen fahimtar hasashen da wanda ya kafa Intel Gordon Moore ya yi a 1965 cewa "yawan haɗakar transistor zai ninka cikin shekaru 1.5 zuwa 2" (wanda aka fi sani da "Dokar Moore").

Etching ba tsari ne na “ƙari” kamar sakawa ko haɗin kai ba, amma tsari ne na “raguwa”. Bugu da ƙari, bisa ga hanyoyi daban-daban na gogewa, an raba shi zuwa kashi biyu, wato "rigar etching" da "bushe etching". Don sanya shi a sauƙaƙe, tsohuwar hanya ce ta narkewa kuma ta ƙarshe ita ce hanyar tono.

A cikin wannan labarin, za mu yi bayani a taƙaice halaye da bambance-bambancen kowane fasaha na etching, rigar etching da bushe bushe, da kuma wuraren aikace-aikacen da kowannensu ya dace da su.

Bayanin tsarin etching

An ce fasahar etching ta samo asali ne daga Turai a tsakiyar karni na 15. A lokacin, an zuba acid a cikin farantin tagulla da aka zana don ya lalata tagulla mara kyau, ya zama intaglio. Dabarun jiyya na saman da ke yin amfani da tasirin lalata an san su sosai da “etching.”

Manufar aiwatar da etching a masana'antar semiconductor shine a yanke substrate ko fim a kan ƙasa bisa ga zane. Ta hanyar maimaita matakan shirye-shiryen samar da fina-finai, daukar hoto, da etching, ana sarrafa tsarin tsarin zuwa tsari mai girma uku.

Bambanci tsakanin rigar etching da bushe etching

Bayan aikin photolithography, abin da aka fallasa ya zama rigar ko bushe a cikin tsarin etching.

Wet etching yana amfani da bayani don tsagewa da goge saman. Kodayake ana iya sarrafa wannan hanya cikin sauri da arha, rashin amfaninsa shine daidaiton sarrafawa ya ɗan ragu kaɗan. Saboda haka, an haifi busassun etching a kusa da 1970. Dry etching ba ya amfani da mafita, amma yana amfani da iskar gas don buga saman ƙasa don karce shi, wanda ke da girman daidaiton aiki.

"Isotropy" da "Anisotropy"

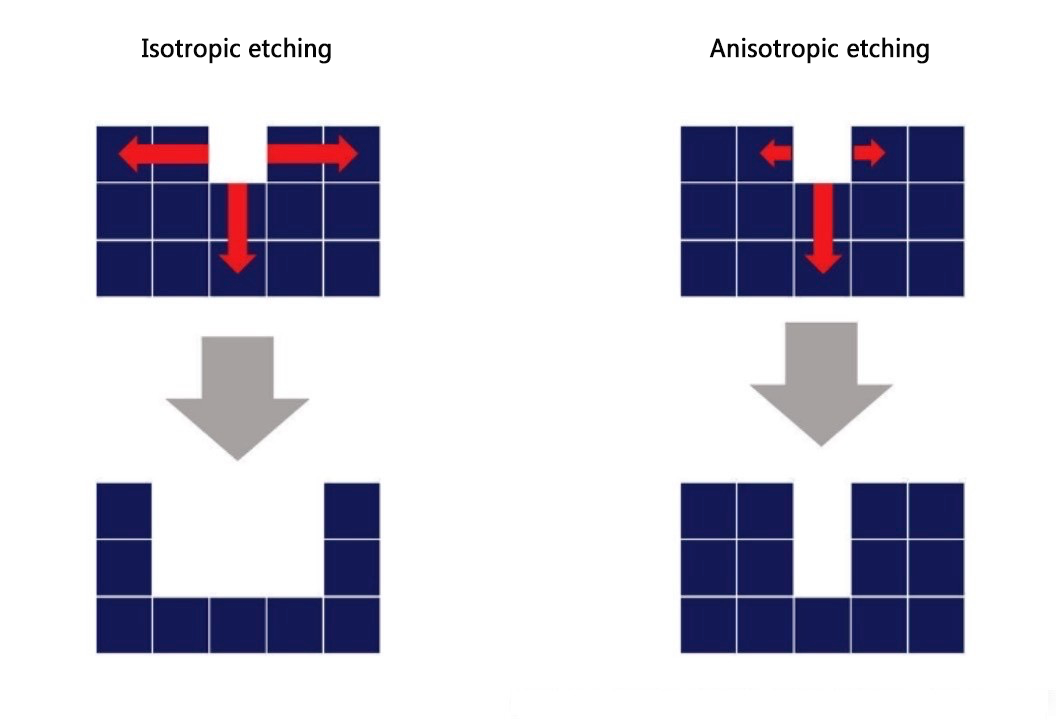

Lokacin gabatar da bambanci tsakanin rigar etching da bushe etching, kalmomi masu mahimmanci sune "isotropic" da "anisotropic". Isotropy yana nufin cewa abubuwan da ke cikin jiki na kwayoyin halitta da sararin samaniya ba sa canzawa tare da shugabanci, kuma anisotropy yana nufin cewa kayan jiki na kwayoyin halitta da sararin samaniya sun bambanta da shugabanci.

Isotropic etching yana nufin cewa etching yana gudana ne da adadin daidai da adadin a kusa da wani wuri, kuma anisotropic etching yana nufin cewa etching yana gudana ta hanyoyi daban-daban a kusa da wani wuri. Misali, a cikin etching yayin masana'antar semiconductor, ana yawan zaɓin anisotropic etching ta yadda kawai alkiblar da ake niyya ta goge, ta bar sauran kwatance.

Hotunan "Isotropic Etch" da "Anisotropic Etch"

Hotunan "Isotropic Etch" da "Anisotropic Etch"

Rigar etching ta amfani da sinadarai.

Wet etching yana amfani da halayen sinadarai tsakanin sinadari da sinadarai. Tare da wannan hanya, anisotropic etching ba zai yiwu ba, amma ya fi wuya fiye da isotropic etching. Akwai hane-hane da yawa akan haɗin mafita da kayan aiki, kuma yanayi kamar zafin jiki na ƙasa, maida hankali, da ƙarin adadin dole ne a sarrafa shi sosai.

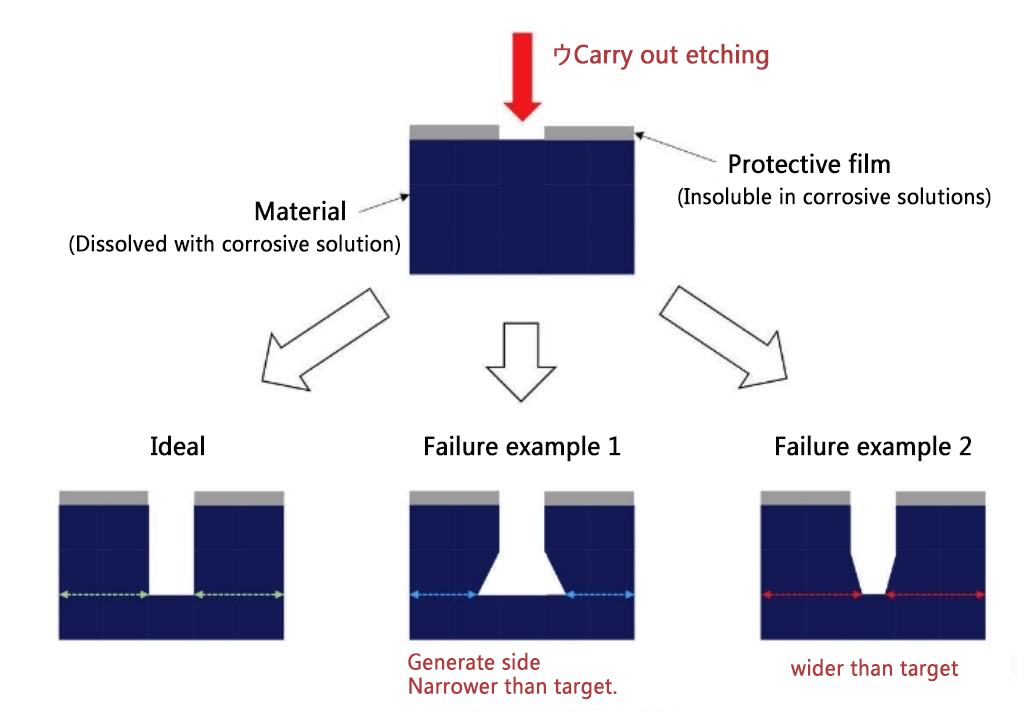

Ko ta yaya aka daidaita yanayin, rigar etching yana da wahala a cimma kyakkyawan aiki a ƙasa da μm. Ɗayan dalili na wannan shine buƙatar sarrafa gefen etching.

Ƙarƙashin sassa wani al'amari ne wanda kuma aka sani da rashin yankewa. Ko da ana fatan cewa kayan za a narkar da su kawai a cikin madaidaiciyar hanya (zurfin zurfin) ta hanyar rigar etching, ba zai yiwu ba don hana gaba ɗaya maganin daga bugun tarnaƙi, don haka rushewar kayan a cikin layi daya ba makawa zai ci gaba. . Saboda wannan al'amari, rigar etching ba da gangan ba yana haifar da sassan da suka fi kunkuntar faɗin manufa. Ta wannan hanyar, lokacin sarrafa samfuran da ke buƙatar ingantaccen iko na yanzu, sake fasalin yana da ƙasa kuma ba shi da tabbas.

Misalai masu yuwuwar gazawa a cikin Rigar Etching

Misalai masu yuwuwar gazawa a cikin Rigar Etching

Me yasa bushe etching ya dace da micromachining

Bayanin Mai alaƙa da Dry etching wanda ya dace da etching anisotropic ana amfani dashi a cikin matakan masana'antu na semiconductor waɗanda ke buƙatar aiki mai mahimmanci. Dry etching yawanci ana kiransa da etching ion etching (RIE), wanda kuma yana iya haɗawa da etching plasma da sputter etching a cikin ma'ana mai faɗi, amma wannan labarin zai mai da hankali kan RIE.

Don bayyana dalilin da ya sa anisotropic etching ya fi sauƙi tare da bushe etching, bari mu dubi tsarin RIE. Abu ne mai sauƙi a fahimta ta hanyar raba tsarin bushewar etching da gogewa zuwa nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan za a iya fahimtar su.

Chemical etching yana faruwa a matakai uku. Na farko, iskar gas mai amsawa suna adsorbed a saman. Ana samar da samfuran amsawa daga iskar gas da kayan da aka yi amfani da su, kuma a ƙarshe samfuran halayen suna desorbed. A cikin etching na jiki na gaba, ana yin maƙallan a tsaye a ƙasa ta hanyar yin amfani da iskar gas na argon a tsaye zuwa ga substrate.

Chemical etching yana faruwa a isotropically, yayin da etching ta jiki na iya faruwa ta anisotropically ta hanyar sarrafa alkiblar aikace-aikacen gas. Saboda wannan etching na jiki, busassun etching yana ba da damar ƙarin iko akan jagorancin etching fiye da rigar etching.

bushe da rigar etching shima yana buƙatar tsauraran sharuɗɗa iri ɗaya kamar rigar etching, amma yana da haɓakawa fiye da rigar etching kuma yana da abubuwa masu sauƙin sarrafawa da yawa. Don haka, ko shakka babu busasshen etching ya fi dacewa da samar da masana'antu.

Me yasa Har yanzu Ana Bukatar Rigar Etching

Da zarar kun fahimci bushewar etching da alama mai ƙarfi, kuna iya mamakin dalilin da yasa har yanzu jikewar etching ta wanzu. Duk da haka, dalilin yana da sauƙi: rigar etching yana sa samfurin ya zama mai rahusa.

Babban bambanci tsakanin bushe etching da rigar etching ne tsada. Sinadaran da ake amfani da su wajen yin jika ba su da tsada sosai, kuma farashin kayan da kansa an ce ya kai kusan 1/10 na na’urar bushewa. Bugu da ƙari, lokacin sarrafawa yana da ɗan gajeren lokaci kuma ana iya sarrafa nau'i-nau'i masu yawa a lokaci guda, rage farashin samarwa. Sakamakon haka, za mu iya rage farashin samfur, yana ba mu fa'ida akan masu fafatawa. Idan buƙatun don daidaiton sarrafawa ba su da girma, kamfanoni da yawa za su zaɓi rigar etching don ƙarancin samarwa.

An gabatar da tsarin etching a matsayin tsari wanda ke taka rawa a fasahar microfabrication. An raba tsarin etching kusan zuwa rigar etching da bushewar etching. Idan farashin yana da mahimmanci, tsohon ya fi kyau, kuma idan ana buƙatar microprocessing ƙasa da 1 μm, ƙarshen ya fi kyau. Da kyau, ana iya zaɓar tsari bisa ga samfurin da za a samar da farashi, maimakon wanda ya fi kyau.

Lokacin aikawa: Afrilu-16-2024