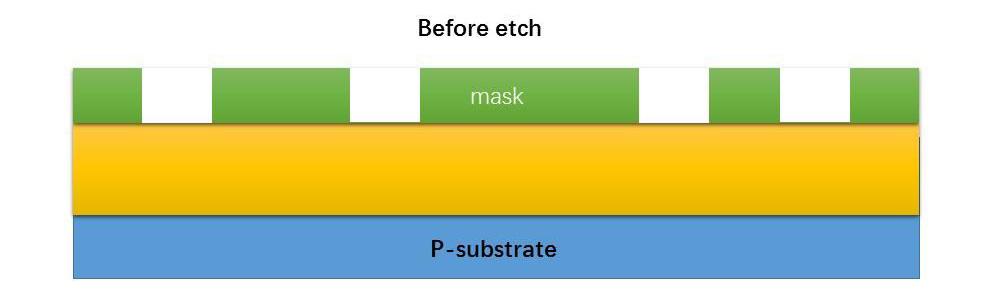

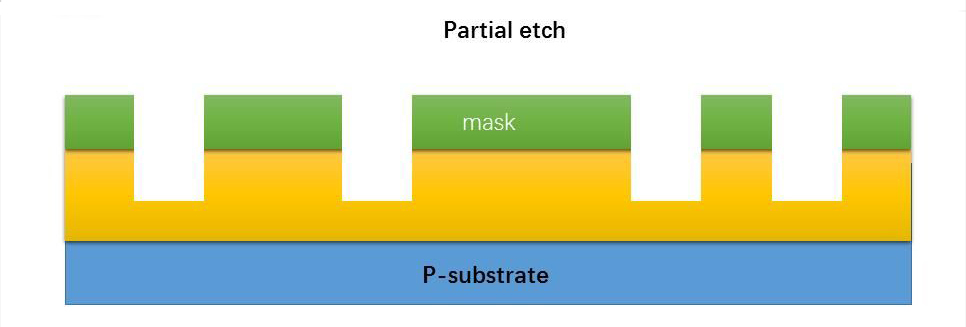

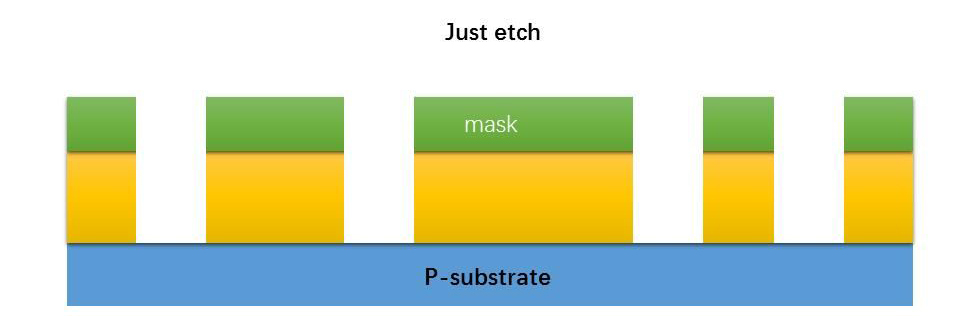

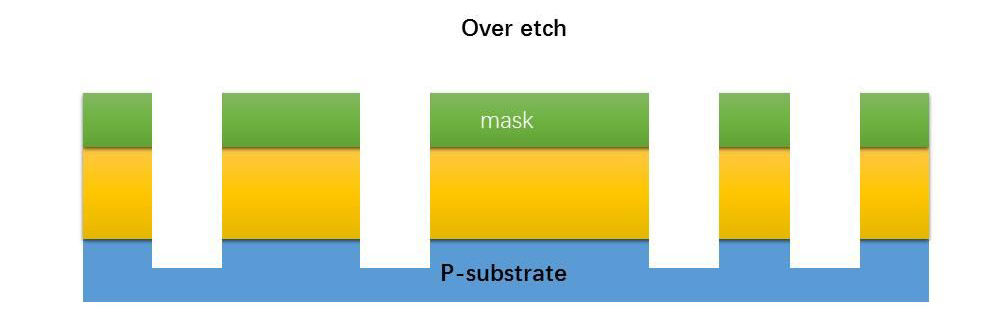

Tsarin etching bushe yakan ƙunshi jihohi huɗu na asali: kafin etching, ɗan ƙaramin etching, kawai etching, da kan etching. Babban halayen su ne etching rate, selectivity, m size, uniformity, and endpoint detection.

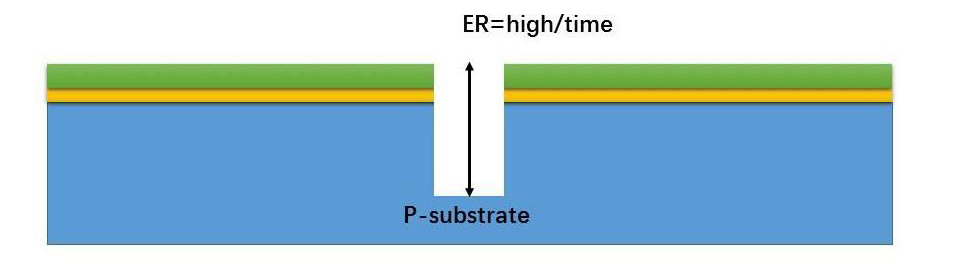

Hoto na 1 Kafin etching

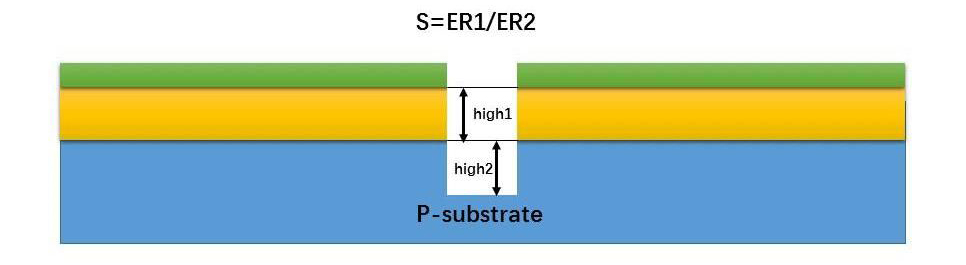

Hoto 2 Sashe na etching

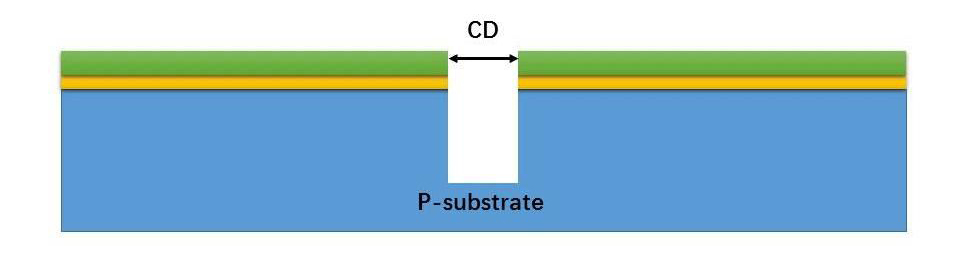

Hoto na 3 Kawai etching

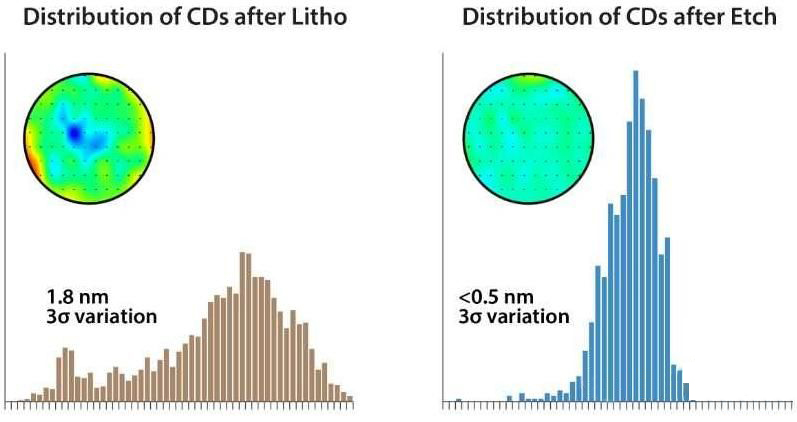

Hoto na 4 Sama da etching

(1) Ƙimar ƙira: zurfin ko kaurin kayan da aka cire a kowane lokaci guda.

Hoto na 5 zane mai ƙima

(2) Selectivity: rabon etching rates na daban-daban etching kayan.

Hoto 6 Zane-zane

(3) Girma mai mahimmanci: girman ƙirar a wani yanki na musamman bayan an kammala etching.

Hoto na 7 Tsarin girma mai mahimmanci

(4) Uniformity: don auna daidaiton ma'aunin mahimmancin etching (CD), gabaɗaya ana siffanta shi da cikakken taswirar CD, dabarar ita ce: U=(Max-Min)/2*AVG.

Hoto na 8 Tsare-tsare Tsare-tsare na Uniformity

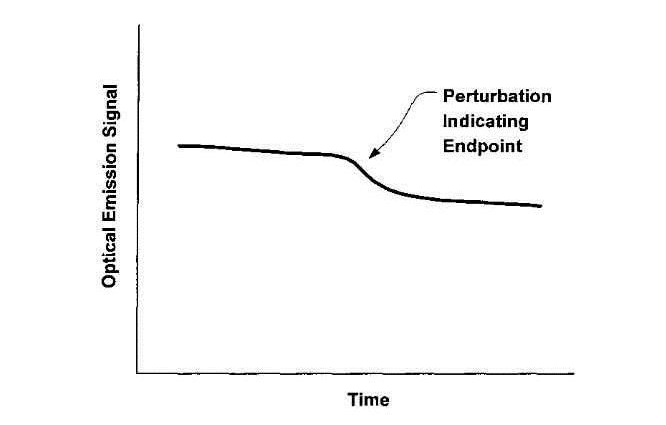

(5) Gano ƙarshen ƙarshen: Yayin aiwatar da etching, ana gano canjin ƙarfin haske koyaushe. Lokacin da wani haske ya tashi ko ya faɗi sosai, ana ƙare etching don alamar kammala wani yanki na etching na fim.

Hoto na 9 Tsarin tsari na ƙarshen batu

A cikin busassun etching, iskar gas yana jin daɗi ta babban mitar (yawanci 13.56 MHz ko 2.45 GHz). A matsa lamba na 1 zuwa 100 Pa, ma'anarsa ta kyauta shine milimita da yawa zuwa santimita da yawa. Akwai manyan nau'ikan bushewar etching guda uku:

•bushewar etching na jiki: hanzari barbashi jiki sa wafer surface

•Chemical bushe etching: iskar gas yana amsa sinadarai tare da saman wafer

•Chemical jiki bushe etching: tsarin etching na jiki tare da halayen sinadarai

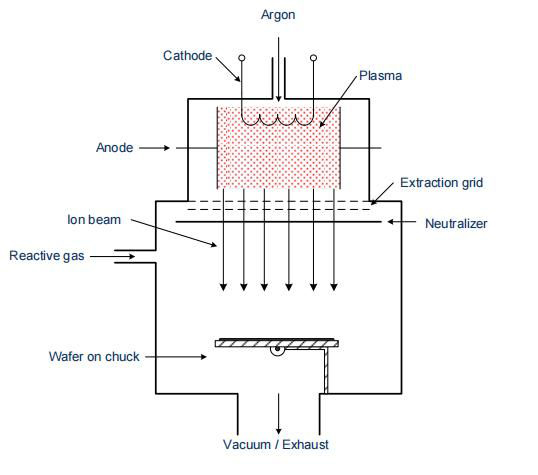

1. Ion beam etching

Ion beam etching (Ion Beam Etching) wani tsari ne na bushewa na zahiri wanda ke amfani da katako mai ƙarfi na argon ion tare da kuzarin kusan 1 zuwa 3 keV don haskaka saman kayan. Ƙarfin wutar lantarki yana haifar da tasiri da kuma cire kayan da ke sama. Tsarin etching yana da anisotropic a cikin yanayin ion bim na ion a tsaye ko a tsaye. Koyaya, saboda ƙarancin zaɓin sa, babu takamaiman bambanci tsakanin kayan a matakai daban-daban. Gas ɗin da aka samar da kayan da aka ƙera suna ƙarewa ta hanyar famfo, amma tunda samfuran amsawa ba iskar gas ba ne, ana adana barbashi a bangon wafer ko ɗakin ɗakin.

Don hana samuwar ƙwayoyin cuta, ana iya shigar da iskar gas na biyu a cikin ɗakin. Wannan gas zai amsa tare da ions argon kuma ya haifar da tsarin etching na jiki da sinadarai. Wani sashe na iskar gas zai amsa tare da kayan da ke saman, amma kuma zai yi amsa tare da barbashi da aka goge don samar da iskar gas. Kusan kowane nau'in kayan ana iya siffanta su ta wannan hanyar. Saboda radiation na tsaye, lalacewa a kan bangon tsaye yana da ƙananan ƙananan (high anisotropy). Koyaya, saboda ƙarancin zaɓin sa da jinkirin ƙimar etching, wannan tsari da wuya a yi amfani da shi a masana'antar semiconductor na yanzu.

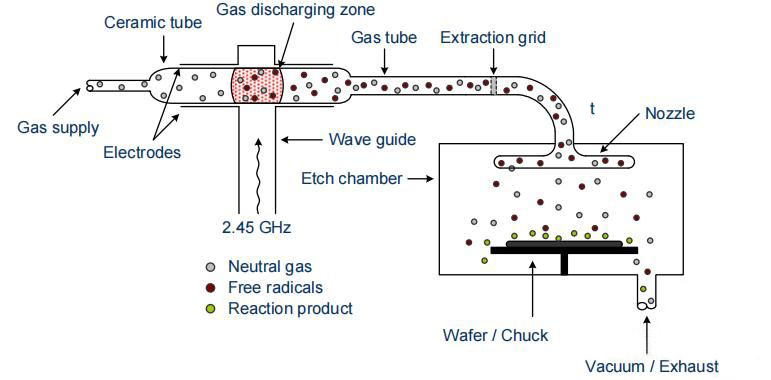

2. Plasma etching

Plasma etching shine cikakken tsari na etching sinadarai, wanda kuma aka sani da bushewar etching. Amfaninsa shine cewa baya haifar da lalacewar ion a saman wafer. Tun da nau'in nau'i mai aiki a cikin iskar gas yana da 'yanci don motsawa kuma tsarin etching shine isotropic, wannan hanya ta dace don cire dukkanin fim din fim (misali, tsaftace gefen baya bayan da iskar oxygenation).

Reactor na ƙasa shine nau'in reactor da aka saba amfani dashi don etching plasma. A cikin wannan reactor, ana haifar da plasma ta hanyar tasirin ionization a cikin babban filin lantarki na 2.45GHz kuma an rabu da wafer.

A cikin yanki na fitar da iskar gas, ana haifar da ƙwayoyin cuta daban-daban saboda tasiri da tashin hankali, ciki har da radicals kyauta. radicals free su ne tsaka tsaki atom ko kwayoyin halitta tare da unsaturated electrons, don haka suna da matukar amsawa. A cikin tsarin etching na plasma, ana amfani da wasu iskar gas masu tsaka-tsaki, irin su tetrafluoromethane (CF4), waɗanda aka shigar da su a cikin wurin fitar da iskar gas don samar da nau'i mai aiki ta hanyar ionization ko lalata.

Misali, a cikin iskar CF4, an shigar da shi a cikin wurin fitar da iskar gas kuma ya lalace ya zama radicals na fluorine (F) da kwayoyin difluoride na carbon (CF2). Hakazalika, fluorine (F) na iya bazuwa daga CF4 ta ƙara oxygen (O2).

2 CF4 + O2 —> 2 COF2 + 2 F2

Kwayoyin fluorine na iya kasu kashi biyu masu zaman kansu atom na fluorine a ƙarƙashin makamashin yankin da ke fitar da iskar gas, kowane ɗayansu yana da radical na fluorine. Tun da kowane zarra na fluorine yana da electrons valence guda bakwai kuma yana ƙoƙarin cimma daidaitaccen tsarin lantarki na iskar gas, duk suna da ƙarfi sosai. Bugu da ƙari, tsaka-tsaki na radicals free fluorine, za a caje barbashi kamar CF+4, CF+3, CF+2, da dai sauransu a cikin yankin fitar da iskar gas. Daga baya, duk waɗannan barbashi da radicals kyauta ana shigar dasu cikin ɗakin etching ta cikin bututun yumbu.

Za a iya toshe barbashi da aka caje ta hanyar cirewa ko kuma a sake haɗa su a cikin tsarin samar da kwayoyin tsaka-tsaki don sarrafa halayensu a ɗakin etching. Hakazalika radicals masu kyauta na fluorine za su fuskanci sake hadewa na wani bangare, amma har yanzu suna aiki sosai don shiga dakin etching, amsa sinadarai a saman wafer kuma suna haifar da cire kayan. Sauran barbashi tsaka tsaki ba sa shiga cikin tsarin etching kuma ana cinye su tare da samfuran amsawa.

Misalai na siraran fina-finai waɗanda za a iya siffanta su a cikin etching plasma:

• Silicon: Si + 4F—> SiF4

• Silicon dioxide: SiO2 + 4F—> SiF4 + O2

• Silicon nitride: Si3N4 + 12F—> 3SiF4 + 2N2

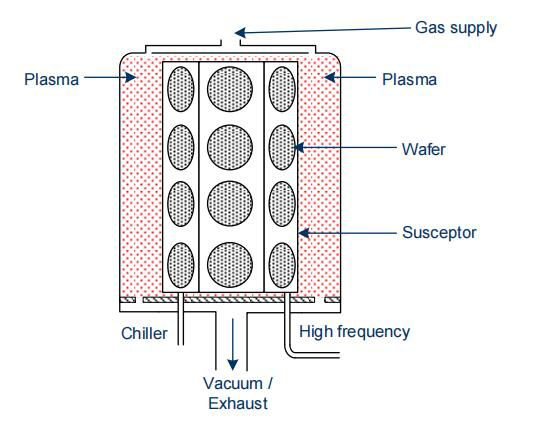

3. Reactive ion etching (RIE)

Reactive ion etching tsari ne na sinadari-jiki wanda zai iya sarrafa daidaitaccen zaɓi, bayanin martaba, ƙimar etching, daidaituwa da maimaitawa. Yana iya cimma bayanan martaba na isotropic da anisotropic etching kuma saboda haka yana ɗaya daga cikin mahimman matakai don gina fina-finai na bakin ciki daban-daban a masana'antar semiconductor.

A lokacin RIE, ana sanya wafer akan na'urar lantarki mai ƙarfi (HF electrode). Ta hanyar tasirin ionization, ana samar da plasma wanda a cikinsa akwai electrons kyauta da ions masu cajin gaske. Idan an yi amfani da ingantacciyar wutar lantarki a kan lantarki na HF, electrons na kyauta suna taruwa a saman wutar lantarki kuma ba za su iya sake barin wutar lantarki ba saboda kusancin lantarki. Saboda haka, ana cajin na'urorin zuwa -1000V (bias voltage) ta yadda jinkirin ions ba zai iya bin filin lantarki da ke canzawa cikin sauri zuwa na'urar caji mara kyau ba.

A lokacin ion etching (RIE), idan ma'anar free hanya na ions yana da girma, sun buga wafer surface a kusan perpendicular shugabanci. Ta wannan hanyar, ions da aka haɓaka suna fitar da kayan kuma su samar da halayen sinadarai ta hanyar etching ta jiki. Tunda ba a shafi bangon gefe na gefe ba, bayanin martabar etch ya kasance anisotropic kuma lalacewa ta ƙasa kaɗan ce. Koyaya, zaɓin ba ya da girma sosai saboda tsarin etching na zahiri shima yana faruwa. Bugu da ƙari, haɓakar ions yana haifar da lalacewa ga farfajiyar wafer, wanda ke buƙatar maganin zafi don gyarawa.

Sashin sinadarai na tsarin etching yana kammala ta hanyar radicals masu kyauta suna amsawa tare da saman kuma ions suna bugun kayan jiki ta jiki don kada ya sake dawowa a kan wafer ko bangon ɗakin, yana guje wa sabon abu kamar ion beam etching. Lokacin ƙara yawan iskar gas a cikin ɗakin etching, madaidaicin hanyar kyauta na ions yana raguwa, wanda ke ƙara yawan haɗuwa tsakanin ions da kwayoyin gas, kuma ions suna warwatse a wurare daban-daban. Wannan yana haifar da ƙarancin etching na shugabanci, yana sa tsarin etching ya zama mafi sinadarai.

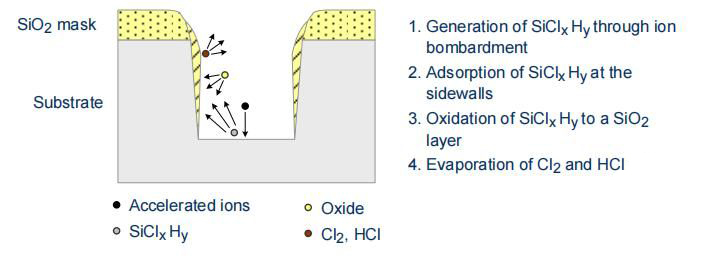

Ana samun bayanan anisotropic etch ta hanyar wucewar bangon gefe yayin etching silicon. Ana shigar da iskar oxygen a cikin ɗakin etching, inda yake amsawa tare da siliki mai ƙyalƙyali don samar da silicon dioxide, wanda aka ajiye akan bangon gefen tsaye. Saboda ion bombardment, oxide Layer a kan kwance wuraren da aka cire, kyale na gefe etching tsari ci gaba. Wannan hanya na iya sarrafa siffar etch profile da tsayin bangon gefe.

Adadin etch yana shafar abubuwa kamar matsa lamba, ikon janareta na HF, iskar gas, ainihin kwararar iskar gas da zafin wafer, kuma ana kiyaye kewayon bambancinsa ƙasa da 15%. Anisotropy yana ƙaruwa tare da ƙara ƙarfin HF, rage matsa lamba da rage yawan zafin jiki. Daidaitaccen tsarin etching yana ƙaddara ta gas, tazarar lantarki da kayan lantarki. Idan nisan lantarki ya yi ƙanƙanta, plasma ba za a iya tarwatsewa daidai gwargwado ba, yana haifar da rashin daidaituwa. Ƙara nisa na lantarki yana rage yawan etching saboda ana rarraba plasma a cikin ƙarar girma. Carbon shine kayan lantarki da aka fi so saboda yana samar da nau'in plasma mai taurin kai ta yadda gefen wafer ya shafi daidai da tsakiyar wafer.

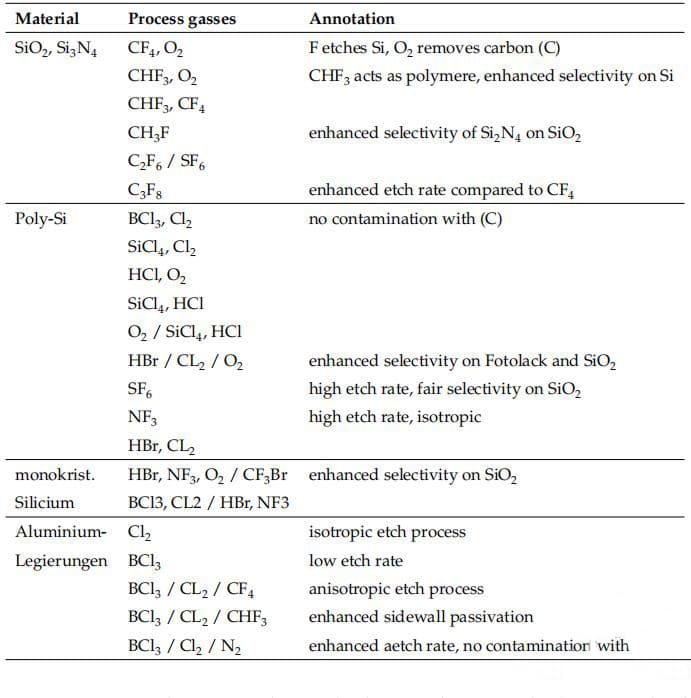

Tsarin iskar gas yana taka muhimmiyar rawa a cikin zaɓin zaɓi da ƙimar etching. Don mahadi na silicon da silicon, ana amfani da fluorine da chlorine galibi don cimma etching. Zaɓin gas ɗin da ya dace, daidaitawar iskar gas da matsa lamba, da sarrafa sauran sigogi kamar zafin jiki da iko a cikin tsari na iya cimma ƙimar etch da ake so, zaɓi, da daidaituwa. Ana daidaita haɓakar waɗannan sigogi yawanci don aikace-aikace da kayan daban-daban.

Tsarin etching bai iyakance ga gas ɗaya ba, cakuda gas, ko ƙayyadaddun sigogin tsari. Misali, ana iya cire oxide na asali akan polysilicon da farko tare da babban adadin etch da ƙarancin zaɓi, yayin da polysilicon za'a iya siffanta shi daga baya tare da zaɓi mafi girma dangane da shimfidar ƙasa.

——————————————————————————————————————————————————— ———————————

Semicera na iya bayarwasassa graphite, taushi / m ji, silicon carbide sassa,CVD silicon carbide sassa,kumaSiC/TaC rufaffiyar sassa tare da cikin kwanaki 30.

Idan kuna sha'awar samfuran semiconductor na sama,don Allah kar a yi shakka a tuntube mu a farkon lokaci.

Lambar waya: +86-13373889683

WhatsApp: +86-15957878134

Email: sales01@semi-cera.com

Lokacin aikawa: Satumba-12-2024