Na'urorin wutar lantarki na Semiconductor sun mamaye babban matsayi a cikin tsarin lantarki na wutar lantarki, musamman ma a cikin yanayin saurin haɓaka fasahohi kamar hankali na wucin gadi, sadarwar 5G da sabbin motocin makamashi, abubuwan da ake buƙata don su an inganta su.

Silicon carbide(4H-SiC) ya zama kyakkyawan abu don kera manyan na'urorin wutar lantarki na semiconductor saboda fa'idodinsa kamar faffadan bandgap, babban ƙarfin zafin jiki, ƙarfin fashewar filin, babban ƙimar drift, kwanciyar hankali sinadarai da juriya na radiation. Duk da haka, 4H-SiC yana da babban taurin, babban ɓarna, ƙarfin rashin kuzarin sinadarai, da wahalar sarrafawa. Ingancin saman wafer ɗin sa yana da mahimmanci don aikace-aikacen na'urori masu girma.

Sabili da haka, inganta ingancin 4H-SiC substrate wafers, musamman cire lalata Layer a kan wafer aiki surface, shi ne mabuɗin don cimma ingantaccen, ƙananan asara da ingantaccen 4H-SiC substrate wafer.

Gwaji

Gwajin yana amfani da nau'in 4-inch N-type 4H-SiC ingot wanda aka girma ta hanyar jigilar tururi ta jiki, wanda ake sarrafa shi ta hanyar yankan waya, niƙa, niƙa mai ƙazanta, niƙa mai kyau da goge baki, kuma yana yin rikodin cire kauri daga saman C da Si surface. da kaurin wafer na ƙarshe a cikin kowane tsari.

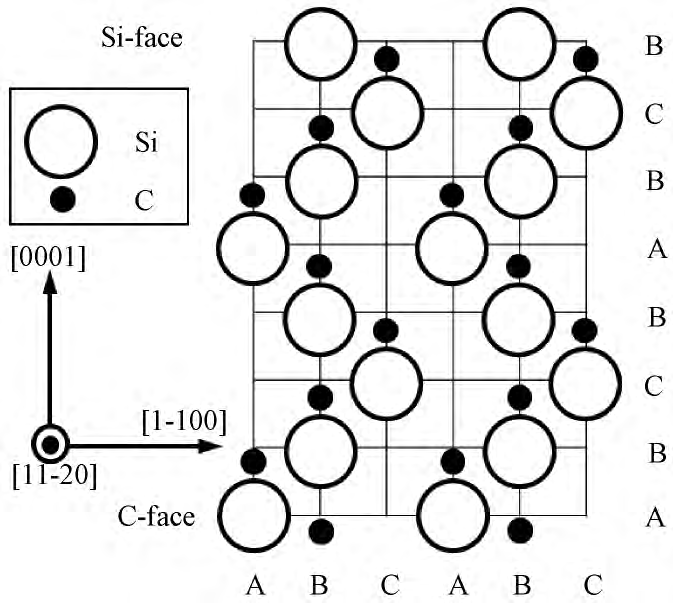

Hoto 1 Tsarin tsari na tsarin crystal na 4H-SiC

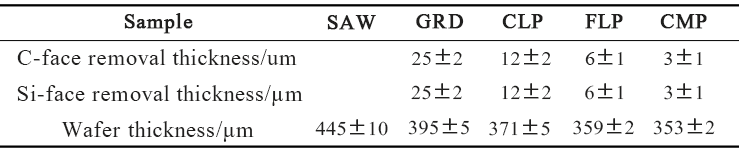

Hoto 2 An cire kauri daga gefen C da Si-gefen 4H-SiC waferbayan matakai daban-daban na sarrafawa da kauri na wafer bayan sarrafawa

Kauri, yanayin yanayin yanayi, rashin ƙarfi da kaddarorin inji na wafer an siffanta su da ma'aunin ma'aunin ma'auni na wafer, bambance-bambancen kutsawa microscope, microscope na ƙarfin atomic, kayan auna ma'aunin ƙasa da nanoindenter. Bugu da kari, an yi amfani da diffractometer X-ray mai girma don kimanta ingancin wafer.

Wadannan matakan gwaji da hanyoyin gwaji suna ba da cikakken goyon bayan fasaha don nazarin ƙimar cire kayan abu da ingancin saman yayin aiki na 4H-SiC wafers.

Ta hanyar gwaje-gwajen, masu binciken sun bincika canje-canje a cikin ƙimar cire kayan abu (MRR), ilimin halittar jiki da rashin ƙarfi, da kaddarorin inji da ingancin crystal na 4H-SiC wafersa cikin matakai daban-daban na sarrafawa (yanke wayoyi, niƙa, niƙa mai laushi, niƙa mai kyau, gogewa).

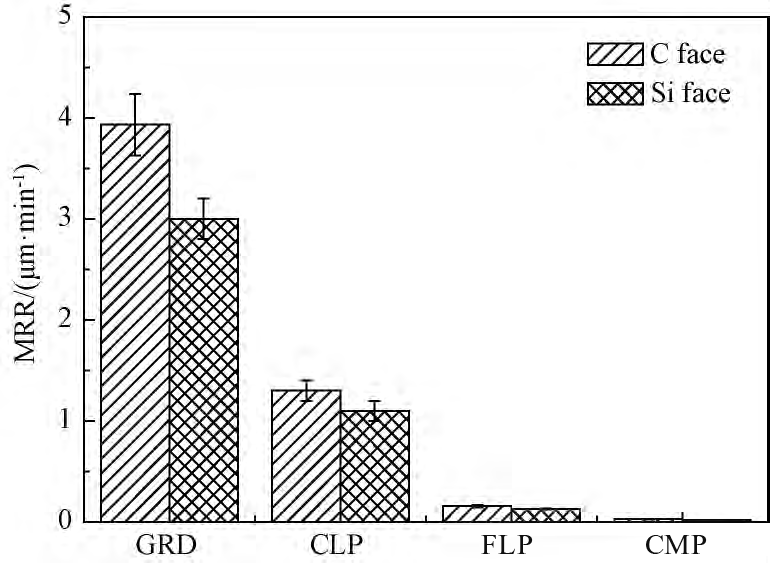

Hoto 3 Adadin cire kayan abu na C-face da Si-face na 4H-SiC wafera matakai daban-daban na sarrafawa

Binciken ya gano cewa saboda anisotropy na kayan aikin injiniya na fuskoki daban-daban na kristal na 4H-SiC, akwai bambanci a cikin MRR tsakanin C-face da Si-face a ƙarƙashin wannan tsari, kuma MRR na C-face ya fi girma fiye da na Si-face. Tare da ci gaban matakan sarrafawa, yanayin yanayin yanayi da rashin ƙarfi na 4H-SiC wafers ana inganta su a hankali. Bayan gogewa, Ra na C-face shine 0.24nm, kuma Ra na Si-face ya kai 0.14nm, wanda zai iya biyan buƙatun ci gaban epitaxial.

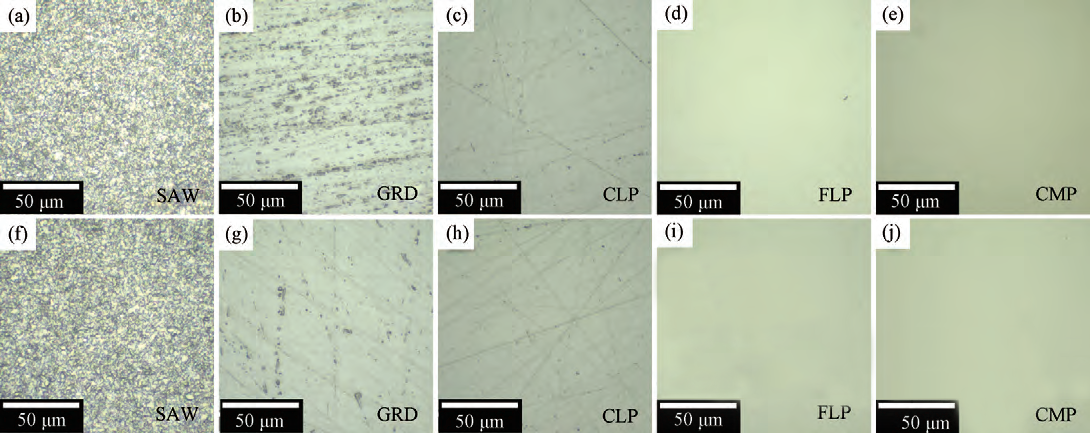

Hoto 4 Hoton microscope na gani na saman C (a ~ e) da Si surface (f ~ j) na 4H-SiC wafer bayan matakan sarrafawa daban-daban

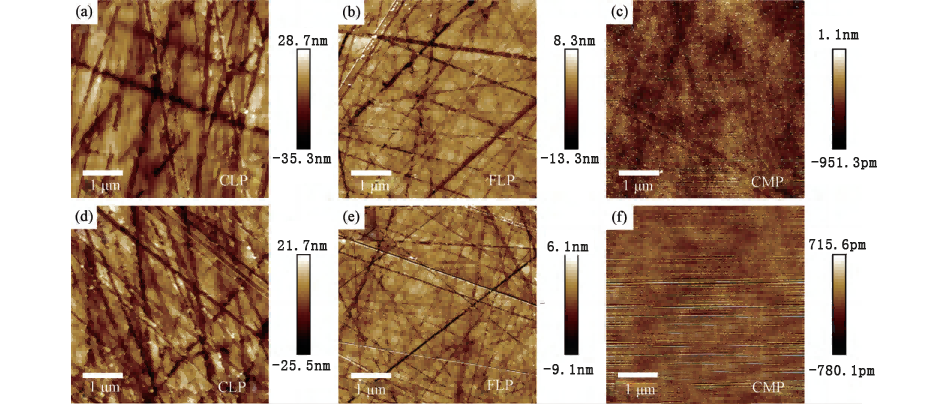

Hoto 5 Hotunan Hotunan Ƙarfin Atom na C (a ~ c) da Si surface (d ~ f) na 4H-SiC wafer bayan matakan sarrafa CLP, FLP da CMP

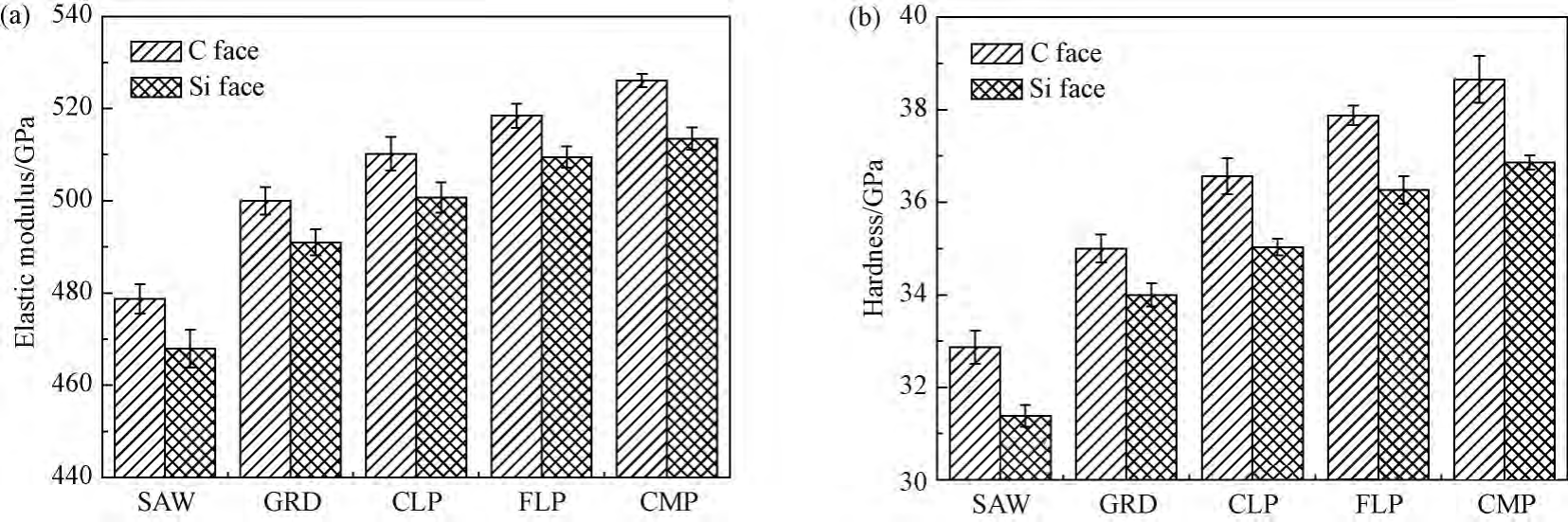

Hoto 6 (a) modulus na roba da (b) taurin saman C da Si surface na 4H-SiC wafer bayan matakan sarrafawa daban-daban

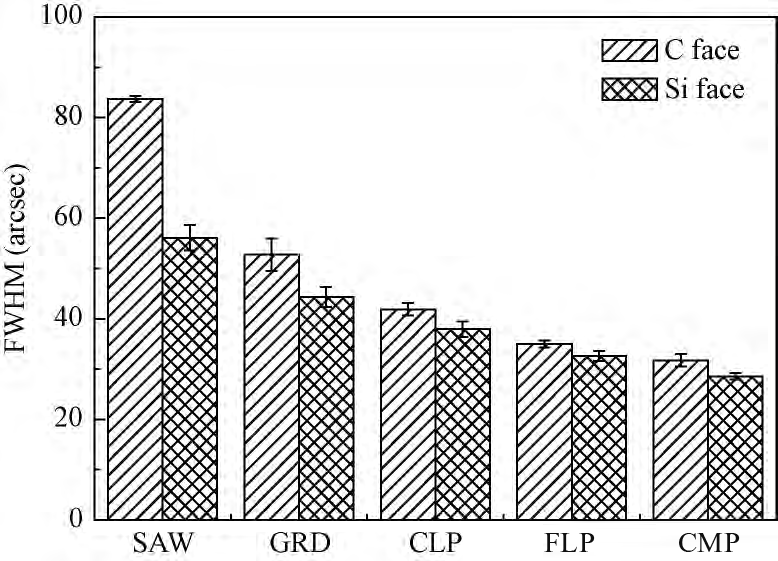

Gwajin kadarorin inji ya nuna cewa saman C na wafer yana da ƙarancin ƙarfi fiye da kayan saman Si, mafi girman matakin karaya yayin aiki, kawar da kayan cikin sauri, da ƙarancin yanayin yanayin yanayin ƙasa da roughness. Cire ɓangarorin da aka lalata akan saman da aka sarrafa shine mabuɗin don haɓaka ingancin walƙiya. Za a iya amfani da nisa na rabin tsayi na 4H-SiC (0004) lanƙwan girgiza don ƙididdigewa da ƙima da ƙididdige shi da kuma nazarin lalacewar farfajiyar wafer.

Hoto 7 (0004) karkarwa rabin nisa na C-face da Si-face na 4H-SiC wafer bayan matakai daban-daban na sarrafawa.

Sakamakon binciken ya nuna cewa za'a iya cire shingen lalacewa na wafer a hankali bayan aikin wafer na 4H-SiC, wanda ya inganta ingantaccen ingancin wafer kuma yana ba da ma'anar fasaha don ingantaccen aiki, ƙarancin hasara da ingantaccen aiki. na 4H-SiC substrate wafers.

Masu binciken sun sarrafa wafer na 4H-SiC ta matakai daban-daban na sarrafawa kamar yankan waya, niƙa, niƙa mai ƙazanta, niƙa mai kyau da goge goge, kuma sun yi nazarin tasirin waɗannan hanyoyin akan ingancin wafer.

Sakamakon ya nuna cewa tare da ci gaba da matakan sarrafawa, ana inganta yanayin yanayin yanayi da rashin ƙarfi na wafer a hankali. Bayan gogewa, ƙarancin C-face da Si-face ya kai 0.24nm da 0.14nm bi da bi, wanda ya dace da buƙatun ci gaban epitaxial. Fuskar C-fuskar wafer tana da ƙarancin tauri fiye da kayan Si-face, kuma ya fi saurin karyewa yayin sarrafawa, wanda ke haifar da ƙarancin yanayin yanayin yanayin ƙasa da rashin ƙarfi. Cire farfajiyar lalacewa na saman da aka sarrafa shine mabuɗin don haɓaka ingancin walƙiya. Rabin nisa na 4H-SiC (0004) lankwasa mai girgiza na iya iya fahimta da kuma daidai da yanayin lalacewar wafer.

Bincike ya nuna cewa za a iya cire ɓarnar da aka lalata a saman 4H-SiC wafers a hankali ta hanyar sarrafa wafer na 4H-SiC, inganta ingantaccen ingancin wafer, samar da ma'anar fasaha don ingantaccen inganci, ƙarancin hasara, da haɓaka. ingancin aiki na 4H-SiC substrate wafers.

Lokacin aikawa: Jul-08-2024