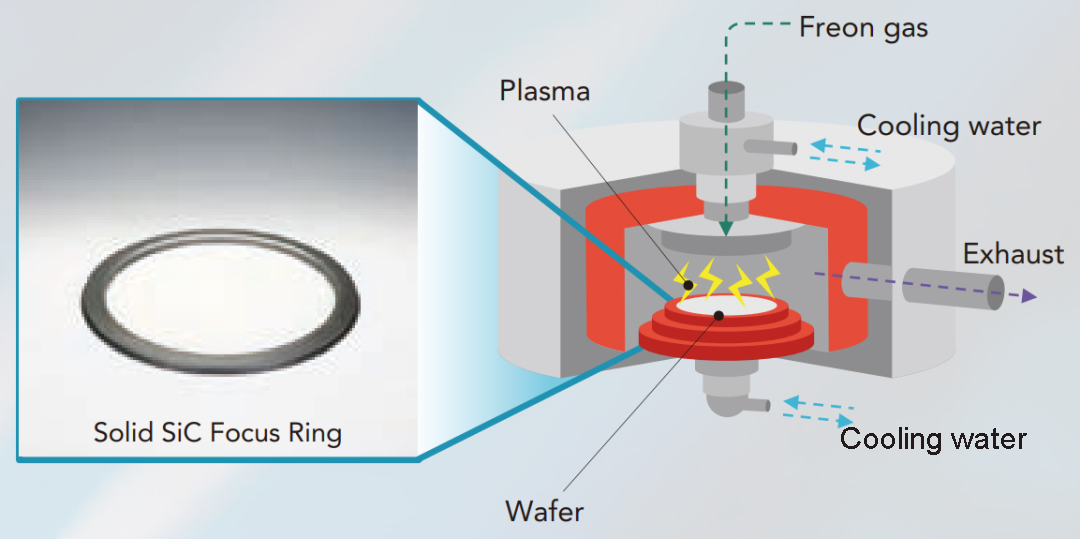

A cikin kayan aikin etching na plasma, abubuwan yumbu suna taka muhimmiyar rawa, gami dazoben mayar da hankali.The zoben mayar da hankali, wanda aka sanya a kusa da wafer kuma a cikin hulɗar kai tsaye tare da shi, yana da mahimmanci don mayar da hankali kan plasma a kan wafer ta hanyar amfani da wutar lantarki zuwa zobe. Wannan yana haɓaka daidaiton tsarin etching.

Aikace-aikace na SiC Focus Zobba a cikin Injin Etching

Abubuwan haɗin SiC CVDa cikin injunan etching, kamarzoben mayar da hankali, iskar gas shawa, platens, da zoben gefuna, ana fifita su saboda ƙarancin reactivity na SiC tare da chlorine da gas na tushen fluorine da haɓakarsa, yana mai da shi kayan aiki mai kyau don kayan aikin etching na plasma.

Fa'idodin SiC a matsayin Maɓalli na Zoben Maɗaukaki

Saboda bayyanar da plasma kai tsaye a cikin ɗakin amsawa, ana buƙatar yin zoben mayar da hankali daga kayan da ke jure jini. Zoben mayar da hankali na al'ada, waɗanda aka yi daga silicon ko ma'adini, suna fama da ƙarancin juriya na etching a cikin plasma na tushen fluorine, wanda ke haifar da lalata da sauri da rage aiki.

Kwatanta Tsakanin Si da CVD SiC Focus Zobba:

1. Mafi Girma:Yana rage girman etching.

2. Faɗin Ƙarƙashin Ƙarfafawa: Yana ba da kyakkyawan rufi.

3. Babban Haɓakawa na thermal & Ƙarƙashin Ƙarfafawa: Mai jure wa zafin zafi.

4. Babban Nauni:Kyakkyawan juriya ga tasiri na inji.

5. Yawan Tauri: Sawa da lalatawa.

SiC tana raba wutar lantarki ta silicon yayin da take ba da juriya mafi girma ga ionic etching. Kamar yadda hadedde miniaturization na kewaye ke ci gaba, buƙatar ƙarin ingantattun hanyoyin etching yana ƙaruwa. Na'urar etching Plasma, musamman waɗanda ke amfani da plasma capacitive hade (CCP), suna buƙatar babban ƙarfin plasma, yinSiC mayar da hankali zobeƙara shahara.

Si da CVD SiC Mayar da Hannun Ma'aunin Ring:

| Siga | Silicon (Si) | CVD Silicon Carbide (SiC) |

| Girma (g/cm³) | 2.33 | 3.21 |

| Band Gap (eV) | 1.12 | 2.3 |

| Ƙarfafa Ƙarfafawa (W/cm°C) | 1.5 | 5 |

| Ƙididdigar Faɗaɗɗen Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙira (x10⁻⁶/°C) | 2.6 | 4 |

| Elastic Modulus (GPa) | 150 | 440 |

| Tauri | Kasa | Mafi girma |

Tsarin Kerawa na SiC Focus Zobba

A cikin kayan aikin semiconductor, CVD (Chemical Vapor Deposition) ana yawan amfani dashi don samar da abubuwan SiC. Ana kera zoben mai da hankali ta hanyar saka SiC cikin takamaiman sifofi ta hanyar jifa da tururi, sannan sarrafa injina don samar da samfurin ƙarshe. Matsakaicin abin da ke tattare da tururi yana daidaitawa bayan ɗimbin gwaji, yin sigogi kamar tsayayya. Koyaya, kayan aikin etching daban-daban na iya buƙatar zoben mayar da hankali tare da juriya daban-daban, waɗanda ke buƙatar sabbin gwaje-gwajen rabo na kayan don kowane ƙayyadaddun bayanai, wanda ke ɗaukar lokaci da tsada.

Ta zabarSiC mayar da hankali zobedagaSemicera Semiconductor, Abokan ciniki za su iya cimma fa'idodin hawan keke mai tsayi da haɓaka aiki ba tare da haɓakar farashi mai yawa ba.

Abubuwan Haɓaka Tsarin Ma'aunin zafi da sauri (RTP).

CVD SiC na keɓaɓɓen kaddarorin zafi sun sa ya dace don aikace-aikacen RTP. Abubuwan RTP, gami da zoben gefuna da faranti, suna amfana daga CVD SiC. A lokacin RTP, ana amfani da bugun jini mai zafi a kan wafers na kowane ɗan gajeren lokaci, sannan kuma saurin sanyaya. CVD SiC gefen zoben, kasancewa na bakin ciki kuma yana da ƙarancin yawan zafin jiki, ba sa riƙe zafi mai mahimmanci, yana sa su rashin tasiri ta hanyar saurin dumama da sanyaya.

Abubuwan Etching Plasma

Babban juriyar sinadarai na CVD SiC ya sa ya dace da aikace-aikacen etching. Yawancin ɗakunan etching suna amfani da faranti na rarraba gas na CVD SiC don rarraba iskar gas, mai ɗauke da dubban ƙananan ramuka don tarwatsawar jini. Idan aka kwatanta da madadin kayan aiki, CVD SiC yana da ƙaramin amsawa tare da chlorine da gas ɗin fluorine. A cikin bushewar etching, abubuwan CVD SiC kamar zoben mayar da hankali, farantin ICP, zoben iyaka, da ruwan shawa ana yawan amfani da su.

Zoben mayar da hankali na SiC, tare da ƙarfin lantarki da aka yi amfani da su don mayar da hankali kan plasma, dole ne su sami isassun ƙarfin aiki. Yawanci da aka yi da siliki, zoben mayar da hankali suna fallasa ga iskar gas mai ɗauke da fluorine da chlorine, wanda ke haifar da lalata da babu makawa. Zoben mayar da hankali na SiC, tare da mafi girman juriyar lalata su, suna ba da tsawon rayuwa idan aka kwatanta da zoben silicon.

Kwatanta Rayuwar Rayuwa:

Zoben Mayar da hankali na SiC:Ana maye gurbin kowane kwanaki 15 zuwa 20.

Zoben Mayar da hankali na Silicon:Ana maye gurbin kowane kwanaki 10 zuwa 12.

Duk da zoben SiC kasancewa sau 2 zuwa 3 ya fi tsada fiye da zoben silicon, tsawaita sake zagayowar yana rage farashin maye gurbin gabaɗaya, kamar yadda duk abubuwan lalacewa a cikin ɗakin ana maye gurbinsu lokaci guda lokacin da aka buɗe ɗakin don maye gurbin zobe.

Semicera Semiconductor's SiC Focus Rings

Semicera Semiconductor yana ba da zoben mayar da hankali na SiC akan farashi kusa da na zoben silicon, tare da lokacin jagora na kusan kwanaki 30. Ta hanyar haɗa zoben mayar da hankali na Semicera's SiC cikin kayan aikin etching na plasma, inganci da tsawon rai suna inganta sosai, rage ƙimar kulawa gabaɗaya da haɓaka haɓakar samarwa. Bugu da ƙari, Semicera na iya keɓance juriya na zoben mayar da hankali don saduwa da takamaiman buƙatun abokin ciniki.

Ta zaɓar zoben mayar da hankali na SiC daga Semicera Semiconductor, abokan ciniki za su iya cimma fa'idodin hawan keke mai tsayi da ingantaccen aiki ba tare da haɓakar farashi ba.

Lokacin aikawa: Yuli-10-2024