Silicon carbide (SiC) substrates suna da lahani da yawa waɗanda ke hana aiki kai tsaye. Don ƙirƙirar guntu wafers, wani takamaiman fim ɗin-crystal dole ne a girma a kan SiC substrate ta hanyar tsarin epitaxial. Ana kiran wannan fim da lakabin epitaxial. Kusan duk na'urorin SiC an gane su akan kayan epitaxial, kuma kayan aikin SiC masu inganci na homoepitaxial sun zama tushe don haɓaka na'urar SiC. Ayyukan kayan aikin epitaxial kai tsaye yana ƙayyade aikin na'urorin SiC.

Na'urorin SiC masu girma na yanzu da babban abin dogaro suna ƙaddamar da buƙatu masu tsauri akan yanayin halittar ƙasa, ƙarancin lahani, daidaiton doping, da daidaiton kauri naepitaxialkayan aiki. Samun girma-girma, ƙananan ƙarancin lahani, da kuma babban tsari na SiC epitaxy ya zama mahimmanci ga ci gaban masana'antar SiC.

Samar da ingantaccen SiC epitaxy ya dogara da ci-gaba matakai da kayan aiki. A halin yanzu, hanyar da aka fi amfani da ita don ci gaban SiC epitaxial shineAbubuwan Turin Sinadarai (CVD).CVD yana ba da madaidaicin iko akan kauri na fim ɗin epitaxial da maida hankali na doping, ƙarancin ƙarancin lahani, matsakaicin girma girma, da sarrafa tsari mai sarrafa kansa, yana mai da shi ingantaccen fasaha don aikace-aikacen kasuwanci mai nasara.

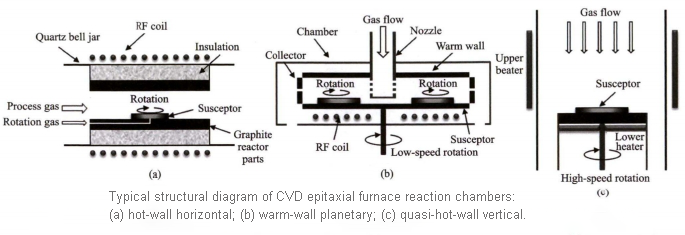

SiC CVD epitaxygabaɗaya yana ɗaukar bango mai zafi ko kayan aikin CVD mai dumama. Babban yanayin zafi (1500-1700 ° C) yana tabbatar da ci gaba da nau'in crystalline na 4H-SiC. Dangane da alakar da ke tsakanin jagorar kwararar iskar gas da farfajiyar ƙasa, za a iya rarraba ɗakunan amsawar waɗannan tsarin CVD zuwa sifofi na kwance da a tsaye.

Ana yin la'akari da ingancin wutar lantarki ta SiC akan abubuwa uku: aikin haɓaka epitaxial (ciki har da daidaituwar kauri, daidaituwar doping, ƙarancin lahani, da ƙimar girma), aikin zafin kayan aiki (ciki har da ƙimar dumama / sanyaya, matsakaicin zafin jiki, da daidaiton zafin jiki). ), da kuma ingancin farashi (ciki har da farashin naúrar da ƙarfin samarwa).

Bambance-Bambance Tsakanin Nau'o'in Uku Na SiC Epitaxial Growth Furnaces

1.Katanga mai zafi Horizontal CVD Systems:

-Siffofin:Gabaɗaya yana fasalta tsarin girman girman wafer guda ɗaya wanda ke gudana ta hanyar jujjuyawar iyo na iskar gas, suna samun ingantattun ma'aunin intra-wafer.

- Samfurin wakilci:LPE's Pe1O6, mai ikon sauke wafer na atomatik a 900°C. An san shi don ƙimar girma mai girma, gajeriyar hawan epitaxial, da daidaiton intra-wafer da aikin tsaka-tsaki.

-Ayyuka:Don 4-6 inch 4H-SiC epitaxial wafers tare da kauri ≤30μm, yana cimma intra-wafer kauri mara daidaituwa ≤2%, doping maida hankali ba Uniformity ≤5%, surface lahani yawa ≤1 cm-², da lahani-free surface area (2mm × 2mm Kwayoyin) ≥90%.

-Masana'antun Cikin Gida: Kamfanoni kamar Jingsheng Mechatronics, CETC 48, North Huachuang, da Nasset Intelligent sun ƙera irin wannan kayan aiki na SiC na epitaxial guda ɗaya tare da haɓaka haɓaka.

2.Dumi-bangon Planetary CVD Systems:

-Siffofin:Yi amfani da ginshiƙan tsarin tsarin duniya don haɓakar wafer da yawa a kowane tsari, yana haɓaka ingantaccen fitarwa sosai.

-Samfuran Wakilai:Aixtron's AIXG5WWC (8x150mm) da kuma jerin G10-SiC (9x150mm ko 6x200mm).

-Ayyuka:Don 6-inch 4H-SiC epitaxial wafers tare da kauri ≤10μm, yana cimma bambancin kauri tsakanin wafer ± 2.5%, intra-wafer kauri mara daidaituwa 2%, tsaka-tsaki na doping ± 5%, da doping intra-wafer. rashin daidaituwar maida hankali <2%.

-Kalubale:Ƙayyadaddun tallafi a kasuwannin cikin gida saboda rashin bayanan samar da tsari, shingen fasaha a cikin zafin jiki da kula da filin gudana, da R&D mai gudana ba tare da aiwatar da manyan ayyuka ba.

3. Tsare-tsare-tsare-zafi-bangon CVD Tsaye:

- Features:Yi amfani da taimakon injina na waje don jujjuyawar juzu'i mai saurin gaske, rage kauri akan iyaka da haɓaka ƙimar haɓakar epitaxial, tare da fa'idodi na asali a cikin sarrafa lahani.

- Samfuran Wakilai:Nuflare's guda-wafer EPIREVOS6 da EPIREVOS8.

-Ayyuka:Yana samun ƙimar girma sama da 50μm/h, ikon sarrafa lahani a ƙasa da 0.1 cm-², da kauri na intra-wafer da maida hankali na doping marasa daidaituwa na 1% da 2.6%, bi da bi.

-Ci gaban Gida:Kamfanoni irin su Xingsandai da Jingsheng Mechatronics sun kera irin wannan kayan aiki amma ba su sami babban amfani ba.

Takaitawa

Kowane nau'in tsarin uku na kayan haɓakar SiC epitaxial yana da halaye daban-daban kuma ya mamaye takamaiman sassan kasuwa dangane da buƙatun aikace-aikacen. CVD a kwance mai zafi yana ba da ƙimar girma mai sauri da daidaiton inganci da daidaituwa amma yana da ƙarancin samarwa saboda sarrafa wafer guda ɗaya. Dumi-bangon duniya CVD yana haɓaka ingantaccen samarwa amma yana fuskantar ƙalubale a cikin sarrafa daidaiton wafer da yawa. Quasi-hot-bangon tsaye CVD ya yi fice a cikin sarrafa lahani tare da hadadden tsari kuma yana buƙatar kulawa mai yawa da ƙwarewar aiki.

Yayin da masana'antu ke haɓakawa, haɓakawa da haɓakawa a cikin waɗannan sifofin kayan aiki za su haifar da haɓaka ingantaccen saiti, suna taka muhimmiyar rawa wajen saduwa da ƙayyadaddun ƙayyadaddun wafer na epitaxial daban-daban don buƙatun kauri da lahani.

Abũbuwan amfãni da rashin amfani na SiC Epitaxial Growth Furnaces daban-daban

| Nau'in Furnace | Amfani | Rashin amfani | Wakilan Masana'antun |

| Zafafan bango Horizontal CVD | Matsakaicin girma mai sauri, tsari mai sauƙi, kulawa mai sauƙi | Gajeren zagayen kulawa | LPE (Italiya), TEL (Japan) |

| Dumi-bangon Planetary CVD | Babban ƙarfin samarwa, inganci | Tsarin tsari mai rikitarwa, kula da daidaito mai wuya | Aixtron (Jamus) |

| Quasi-zafi-bangon tsaye CVD | Kyakkyawan kula da lahani, dogon sake zagayowar kulawa | Tsarin tsari mai rikitarwa, mai wuyar kulawa | Nuflare (Japan) |

Tare da ci gaba da bunƙasa masana'antu, waɗannan nau'ikan kayan aiki guda uku za su fuskanci haɓaka tsarin haɓakawa da haɓakawa, wanda ke haifar da haɓaka ingantaccen saiti waɗanda suka dace da ƙayyadaddun ƙayyadaddun wafer na epitaxial daban-daban don buƙatun kauri da lahani.

Lokacin aikawa: Jul-19-2024