-

Wadanne hanyoyi ne don gogewar wafer?

Daga cikin dukkan hanyoyin da ke tattare da ƙirƙirar guntu, ƙarshen wafer ɗin shine a yanke shi cikin mutuƙar mutum ɗaya kuma a haɗa shi cikin ƙananan kwalaye da aka rufe tare da ƴan filaye kaɗan kawai fallasa. Za a kimanta guntu bisa ga kofa, juriya, halin yanzu, da ƙimar ƙarfin lantarki, amma ba wanda zai yi la'akari da ...Kara karantawa -

Tushen Gabatarwar Tsarin Ci gaban SiC Epitaxial

Epitaxial Layer shine takamaiman fim ɗin kristal guda ɗaya wanda aka girma akan wafer ta hanyar tsarin epitaxial, kuma wafer ɗin substrate da fim ɗin epitaxial ana kiransa wafer epitaxial. Ta hanyar haɓaka Layer na silicon carbide epitaxial a kan madaidaicin siliki carbide substrate, siliki carbide kamanni epitaxial ...Kara karantawa -

Mabuɗin mahimman bayanai na sarrafa ingancin sarrafa marufi na semiconductor

Mabuɗin Mabuɗin don Ingancin Inganci a cikin Tsarin Marufi na Semiconductor A halin yanzu, fasahar aiwatar da marufi na semiconductor ya inganta sosai kuma an inganta shi. Koyaya, daga hangen nesa gabaɗaya, matakai da hanyoyin shirya marufi na semiconductor ba su kai ga mafi inganci ba.Kara karantawa -

Kalubale a cikin Tsarin Marufi na Semiconductor

Dabarun na yanzu don marufi na semiconductor suna haɓaka sannu a hankali, amma gwargwadon yadda ake ɗaukar kayan aiki da fasaha ta atomatik a cikin marufi na semiconductor kai tsaye yana ƙayyade sakamakon da ake tsammani. Ayyukan marufi na semiconductor har yanzu suna fama da…Kara karantawa -

Bincike da Nazarin Tsarin Marufi na Semiconductor

Bayanin Tsari na Semiconductor Tsarin semiconductor da farko ya ƙunshi amfani da microfabrication da fasahar fina-finai don haɗa haɗin kwakwalwan kwamfuta da sauran abubuwa a cikin yankuna daban-daban, kamar maɓalli da firam. Wannan yana sauƙaƙe fitar da tashoshi na gubar da kuma rufewa tare da ...Kara karantawa -

Sabbin Hanyoyi a Masana'antar Semiconductor: Aikace-aikacen Fasahar Rufe Kariya

Masana'antar semiconductor tana ganin ci gaban da ba a taɓa ganin irinsa ba, musamman a fagen lantarki na silicon carbide (SiC). Tare da manyan kayan wafer da yawa waɗanda ke gudana ko haɓakawa don biyan buƙatun na'urorin SiC a cikin motocin lantarki, wannan ...Kara karantawa -

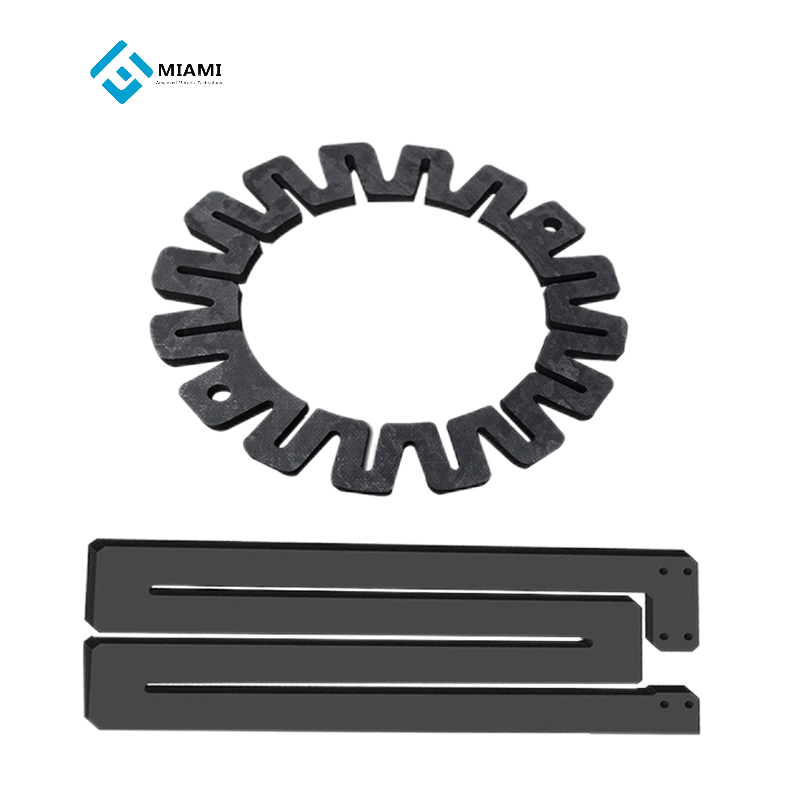

Menene manyan matakai a cikin sarrafa sinadarai na SiC?

Yadda muke samar da matakan sarrafawa don abubuwan SiC sune kamar haka: 1. Crystal Orientation: Yin amfani da diffraction X-ray don daidaita ingot crystal. Lokacin da hasken X-ray aka nufa a fuskar crystal da ake so, kusurwar katako mai rarrabuwar kawuna yana ƙayyade gabacin crystal...Kara karantawa -

Wani abu mai mahimmanci wanda ke ƙayyade ingancin ci gaban silicon crystal guda ɗaya - filin thermal

Tsarin girma na silicon crystal guda ɗaya ana aiwatar da shi gaba ɗaya a cikin filin thermal. Kyakkyawan filin thermal yana da kyau don inganta ingancin kristal kuma yana da ingantaccen ingantaccen crystallization. Zane na filin thermal yana ƙayyade canje-canje da canje-canje ...Kara karantawa -

Menene girma epitaxial?

Girman Epitaxial fasaha ce da ke tsiro da kristal Layer guda akan madaidaicin kristal guda ɗaya (substrate) tare da daidaitawar crystal iri ɗaya kamar maɗaurin, kamar dai ainihin crystal ya faɗa waje. Wannan sabon girma guda crystal Layer na iya bambanta da substrate cikin sharuddan c ...Kara karantawa -

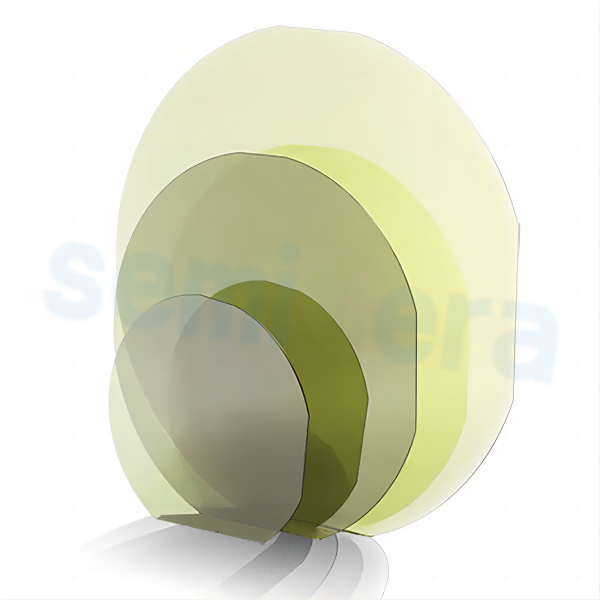

Menene bambanci tsakanin substrate da epitaxy?

A cikin tsarin shirye-shiryen wafer, akwai mahimman hanyoyin haɗin gwiwa guda biyu: ɗaya shine shirye-shiryen substrate, ɗayan kuma shine aiwatar da tsarin epitaxial. Substrate, wafer da aka ƙera a hankali daga kayan kristal guda ɗaya, ana iya saka shi kai tsaye cikin masana'antar wafer ...Kara karantawa -

Bude Halayen Nau'ukan Zafafan Hotuna

Masu dumama ginshiƙi sun fito azaman kayan aikin da babu makawa a cikin masana'antu daban-daban saboda ƙayyadaddun kaddarorinsu da iyawa. Daga dakunan gwaje-gwaje zuwa saitunan masana'antu, waɗannan dumama suna taka muhimmiyar rawa a cikin matakai da suka kama daga haɗakar abubuwa zuwa dabarun nazari. Daga cikin daban-daban ...Kara karantawa -

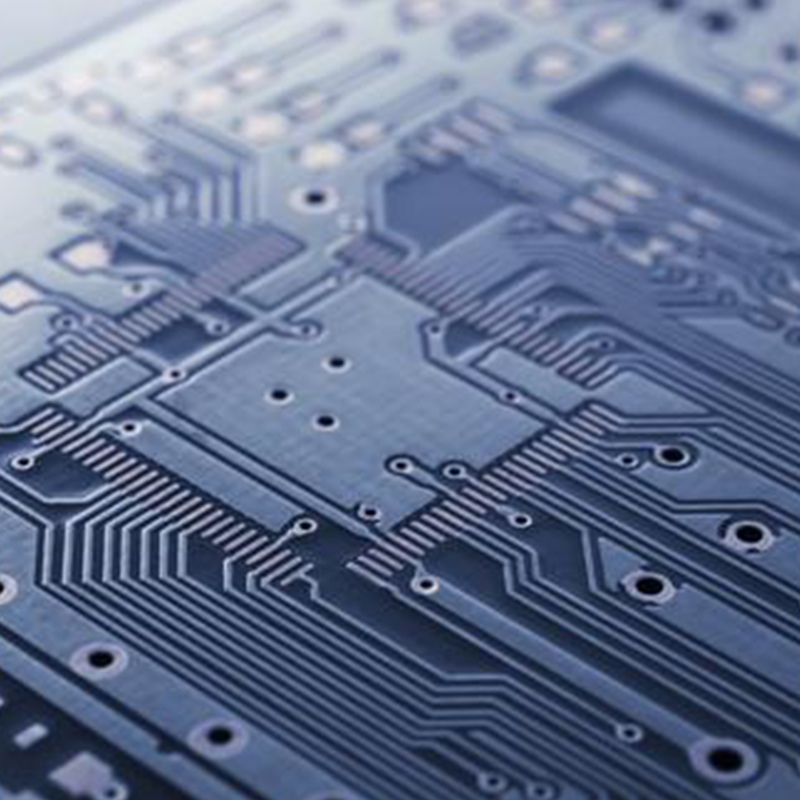

Cikakken bayani game da fa'idodi da rashin amfani na bushewar etching da rigar etching

A cikin masana'anta na semiconductor, akwai wata dabara da ake kira "etching" a lokacin sarrafa kayan aiki ko fim na bakin ciki da aka kafa akan ma'auni. Haɓaka fasahar etching ya taka rawa wajen fahimtar hasashen da wanda ya kafa Intel Gordon Moore ya yi a 1965 cewa “...Kara karantawa