Girman Ci gaban SiC Single Crystal AmfaniCVD-SiC girmaTushen ta Hanyar Sublimation

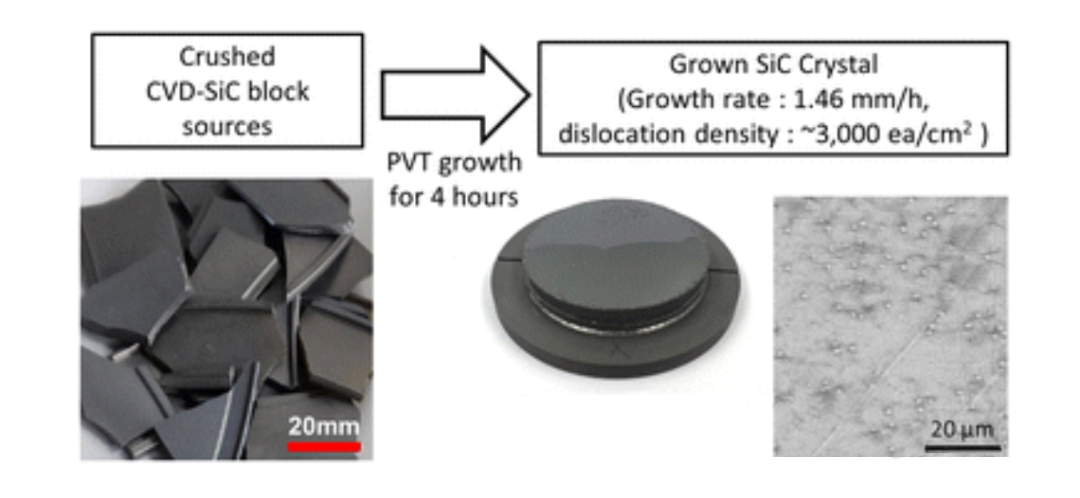

Ta hanyar amfani da sake yin fa'idaCVD-SiC tubalana matsayin tushen SiC, lu'ulu'u na SiC sun sami nasarar girma a cikin ƙimar 1.46 mm/h ta hanyar PVT. Micropipe na kristal da aka girma da ƙarancin rarrabuwar kawuna suna nuna cewa duk da girman girma, ingancin crystal yana da kyau.

Silicon carbide (SiC)ne mai fadi-bandgap semiconductor tare da kyawawan kaddarorin don aikace-aikace a cikin babban ƙarfin lantarki, babban iko, da babban mitar. Bukatar sa ya karu cikin sauri a cikin 'yan shekarun nan, musamman a filin semiconductor. Don aikace-aikacen semiconductor na wutar lantarki, lu'ulu'u guda ɗaya na SiC suna girma ta hanyar haɓaka tushen SiC mai tsafta a 2100-2500 ° C, sa'an nan kuma sake yin recrystallizing akan kristal iri ta amfani da hanyar jigilar tururi ta jiki (PVT), sannan ta hanyar sarrafawa don samun nau'ikan kristal guda ɗaya akan wafers. . A al'adance,SiC crystalsana girma ta amfani da hanyar PVT a ƙimar girma na 0.3 zuwa 0.8 mm / h don sarrafa crystallinity, wanda yake da ɗan jinkiri idan aka kwatanta da sauran kayan kristal guda ɗaya da aka yi amfani da su a aikace-aikacen semiconductor. Lokacin da lu'ulu'u na SiC ke girma a cikin ƙimar girma mai girma ta amfani da hanyar PVT, ƙasƙanci mai inganci ciki har da haɗakar carbon, rage tsafta, haɓakar polycrystalline, samuwar iyakar hatsi, da ɓarna da lahani na porosity ba a yanke hukunci ba. Don haka, saurin haɓakar SiC ba a haɓaka ba, kuma jinkirin haɓakar SiC ya kasance babban cikas ga haɓakar kayan aikin SiC.

A gefe guda, rahotanni na baya-bayan nan game da saurin girma na SiC suna amfani da hanyoyin samar da tururi mai zafi (HTCVD) maimakon hanyar PVT. Hanyar HTCVD tana amfani da tururi mai ɗauke da Si da C a matsayin tushen SiC a cikin reactor. Har yanzu ba a yi amfani da HTCVD don samar da SiC mai girma ba kuma yana buƙatar ƙarin bincike da haɓaka don kasuwanci. Abin sha'awa, ko da a babban girman girma na ~ 3 mm / h, SiC guda lu'ulu'u za a iya girma tare da kyawawa mai kyau ta amfani da hanyar HTCVD. A halin yanzu, an yi amfani da abubuwan haɗin SiC a cikin matakan semiconductor a ƙarƙashin yanayi mara kyau waɗanda ke buƙatar kulawar tsari mai tsafta sosai. Don aikace-aikacen aiwatar da semiconductor, ~ 99.9999% (~ 6N) abubuwan haɗin SiC masu tsabta galibi ana shirya su ta hanyar CVD daga methyltrichlorosilane (CH3Cl3Si, MTS). Koyaya, duk da tsaftar abubuwan CVD-SiC, an yi watsi da su bayan amfani. Kwanan nan, an yi la'akari da abubuwan da aka yi watsi da CVD-SiC a matsayin tushen SiC don haɓakar kristal, kodayake har yanzu ana buƙatar wasu hanyoyin dawowa ciki har da murƙushewa da tsarkakewa don biyan manyan buƙatun tushen ci gaban crystal. A cikin wannan binciken, mun yi amfani da tubalan CVD-SiC da aka jefar don sake sarrafa kayan a matsayin tushen girma lu'ulu'u na SiC. An shirya tubalan CVD-SiC don ci gaban kristal guda ɗaya azaman ɓangarorin da aka sarrafa masu girman girman, daban-daban a cikin sifa da girman girma idan aka kwatanta da kasuwancin SiC foda da aka saba amfani da su a cikin tsarin PVT, saboda haka ana sa ran halayen SiC ɗin ci gaban kristal ɗaya zai zama mahimmanci. daban. Kafin gudanar da gwaje-gwajen ci gaban kristal guda ɗaya na SiC, an yi wasan kwaikwayo na kwamfuta don cimma ƙimar girma mai girma, kuma an saita yankin zafin jiki daidai da haɓakar kristal guda ɗaya. Bayan ci gaban kristal, an kimanta lu'ulu'u masu girma ta hanyar zane-zane na yanki, micro-Raman spectroscopy, babban ra'ayi na X-ray, da synchrotron farin katako na X-ray topography.

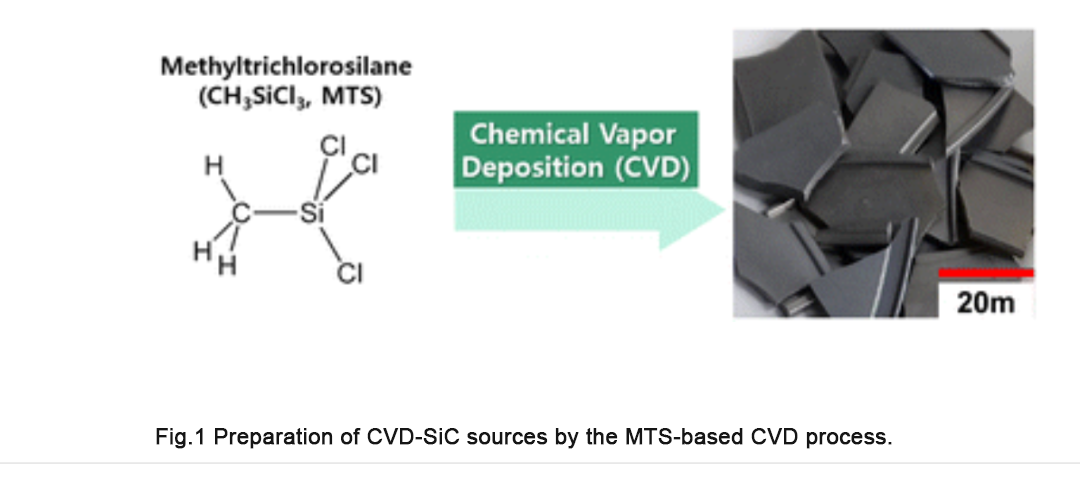

Hoto 1 yana nuna tushen CVD-SiC da aka yi amfani da shi don haɓakar PVT na lu'ulu'u na SiC a cikin wannan binciken. Kamar yadda aka bayyana a cikin gabatarwar, an haɗa abubuwan CVD-SiC daga MTS ta hanyar CVD kuma an tsara su don amfani da semiconductor ta hanyar sarrafa injina. An doped N a cikin tsarin CVD don cimma daidaituwa don aikace-aikacen aiwatar da semiconductor. Bayan yin amfani da su a cikin matakai na semiconductor, an rushe sassan CVD-SiC don shirya tushen don ci gaban crystal, kamar yadda aka nuna a cikin Hoto 1. An shirya tushen CVD-SiC a matsayin faranti tare da matsakaicin kauri na ~ 0.5 mm da matsakaicin girman girman barbashi. 49.75 mm.

Hoto 1: tushen CVD-SiC wanda aka shirya ta hanyar CVD na tushen MTS.

Hoto 1: tushen CVD-SiC wanda aka shirya ta hanyar CVD na tushen MTS.

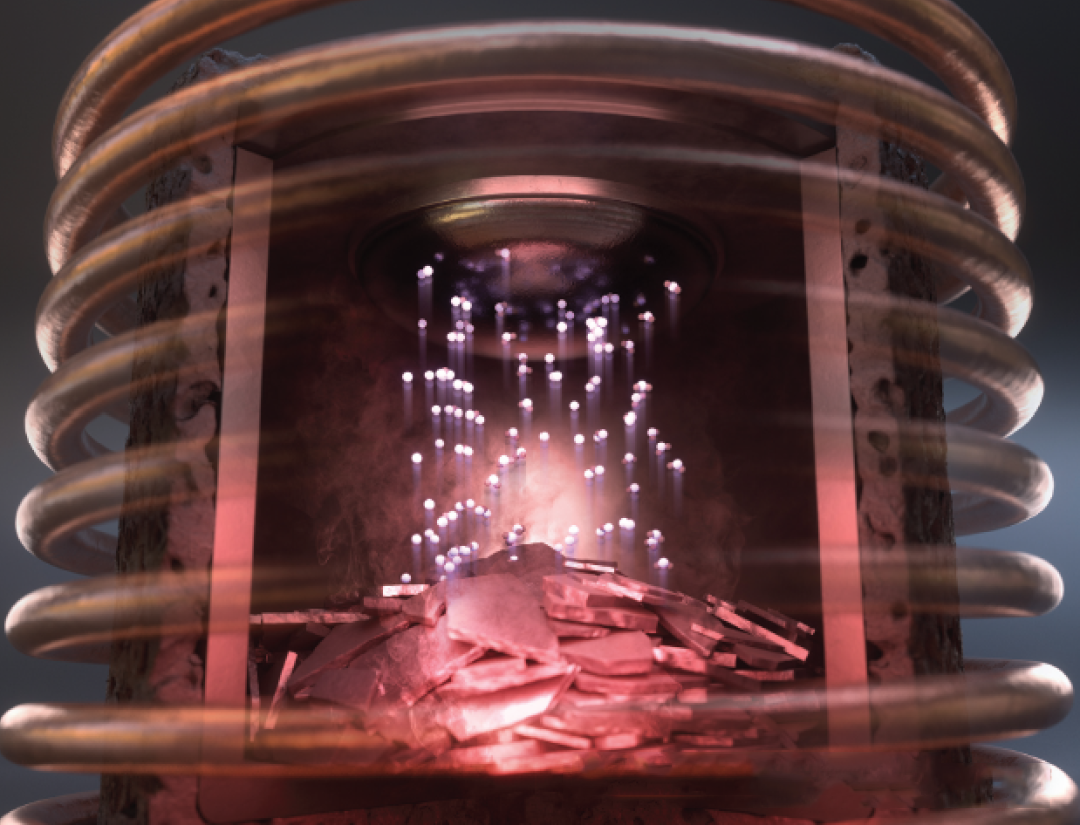

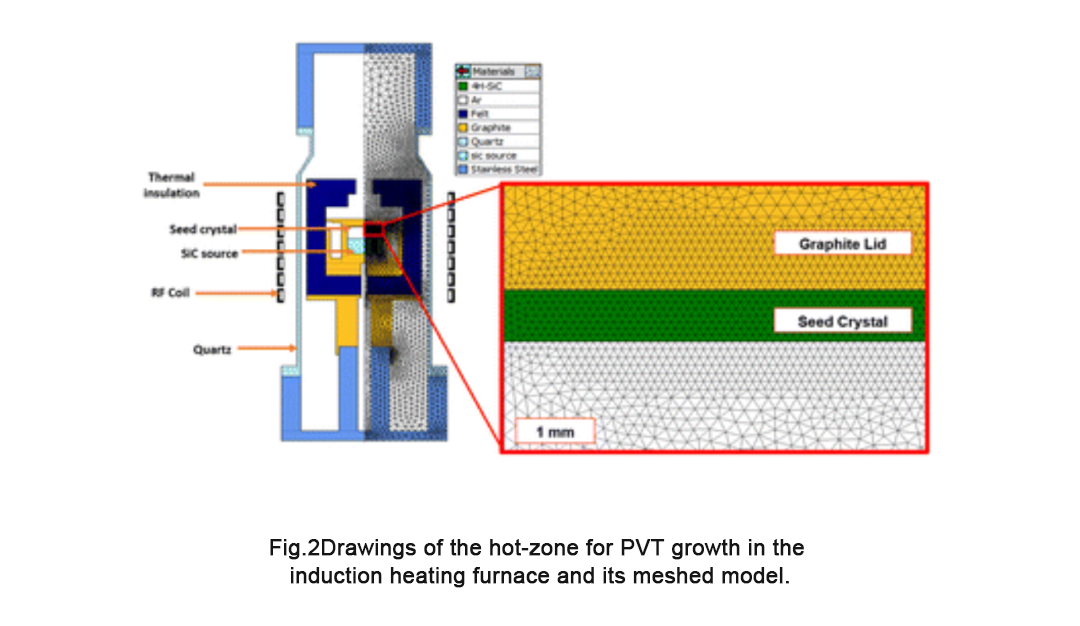

Amfani da tushen CVD-SiC da aka nuna a Hoto 1, SiC lu'ulu'u sun girma ta hanyar PVT a cikin tanderun dumama. Don kimanta rarraba zafin jiki a cikin yankin thermal, an yi amfani da lambar simintin kasuwanci VR-PVT 8.2 (STR, Jamhuriyar Serbia). An tsara reactor tare da yankin thermal azaman ƙirar axisymmetric na 2D, kamar yadda aka nuna a hoto 2, tare da ƙirar ragarsa. Dukkan kayan da aka yi amfani da su a cikin simintin an nuna su a cikin Hoto 2, kuma an jera kaddarorin su a cikin Tebur 1. Dangane da sakamakon kwaikwayo, an yi amfani da lu'ulu'u na SiC ta amfani da hanyar PVT a yanayin zafi na 2250-2350 ° C a cikin yanayin Ar a. 35 Torr na 4 hours. An yi amfani da wafer 4° kashe-axis 4H-SiC azaman iri na SiC. An kimanta lu'ulu'u masu girma ta hanyar micro-Raman spectroscopy (Witec, UHTS 300, Jamus) da XRD mai girma (HRXRD, X'Pert-PROMED, PANalytical, Netherlands). An ƙididdige yawan ƙazanta a cikin lu'ulu'u na SiC da suka girma ta amfani da tsayayyen yanayin ion mass spectrometry (SIMS, Cameca IMS-6f, Faransa). An ƙididdige yawan ɗumbin lu'ulu'u masu girma ta amfani da synchrotron farin katako na X-ray topography a Pohang Light Source.

Hoto 2: Tsarin yanki na thermal da ƙirar raga na haɓakar PVT a cikin tanderun dumama shigar.

Hoto 2: Tsarin yanki na thermal da ƙirar raga na haɓakar PVT a cikin tanderun dumama shigar.

Tunda hanyoyin HTCVD da PVT suna girma lu'ulu'u a ƙarƙashin ma'auni mai ƙarfi na gas a gaban girma, ci gaban saurin ci gaban SiC ta hanyar HTCVD ya haifar da ƙalubalen saurin girma na SiC ta hanyar PVT a cikin wannan binciken. Hanyar HTCVD tana amfani da tushen iskar gas mai sauƙin sarrafawa, yayin da hanyar PVT ke amfani da ingantaccen tushe wanda ba ya sarrafa kwararar kai tsaye. Ƙimar da aka ba da ita ga ci gaban gaba a cikin hanyar PVT za a iya sarrafa shi ta hanyar ƙaddamar da ƙaddamarwa na tushe mai ƙarfi ta hanyar sarrafa rarraba zafin jiki, amma daidaitaccen sarrafa yanayin zafi a cikin tsarin haɓaka mai amfani ba shi da sauƙi a cimma.

Ta hanyar ƙara yawan zafin jiki na tushen a cikin PVT reactor, ƙimar girma na SiC za'a iya ƙarawa ta hanyar ƙara yawan ƙaddamarwa na tushen. Don cimma ingantaccen ci gaban crystal, sarrafa zafin jiki a gaban girma yana da mahimmanci. Don haɓaka ƙimar girma ba tare da samar da polycrystals ba, ana buƙatar samun babban matakin zafin jiki a gaba gaba, kamar yadda aka nuna ta ci gaban SiC ta hanyar hanyar HTCVD. Rashin isassun yanayin zafi na tsaye zuwa bayan hular ya kamata ya watsar da zafin da aka tara a gaban girma ta hanyar radiation thermal zuwa saman girma, wanda zai haifar da samuwar wuce haddi, watau girma polycrystalline.

Dukansu canja wurin taro da tsarin sake sakewa a cikin hanyar PVT suna kama da hanyar HTCVD, kodayake sun bambanta a tushen SiC. Wannan yana nufin cewa saurin haɓakar SiC shima ana iya samunsa lokacin da ƙimar ƙimar tushen SiC ta isa sosai. Koyaya, samun babban ingancin SiC guda lu'ulu'u a ƙarƙashin babban yanayin girma ta hanyar PVT yana da ƙalubale da yawa. Foda na kasuwanci yawanci yana ƙunshe da cakuda ƙanana da manya. Saboda bambance-bambancen makamashi na sararin samaniya, ƙananan ƙwayoyin cuta suna da ƙarancin ƙazanta masu yawa da kuma sublimate kafin manyan barbashi, wanda ke haifar da ƙarancin ƙazanta a farkon matakan girma na crystal. Bugu da ƙari, yayin da ƙaƙƙarfan SiC ke rushewa zuwa nau'in tururi kamar C da Si, SiC2 da Si2C a yanayin zafi mai girma, babu makawa C mai ƙarfi yana samuwa lokacin da tushen SiC ya ƙaru a cikin hanyar PVT. Idan ƙaƙƙarfan C ɗin da aka kafa yana ƙanƙanta da haske sosai, a ƙarƙashin yanayin haɓaka cikin sauri, ƙananan ƙwayoyin C, waɗanda aka sani da “ƙurar C,” ana iya jigilar su zuwa farfajiyar crystal ta wurin canja wurin taro mai ƙarfi, wanda ke haifar da haɗawa a cikin kristal mai girma. Sabili da haka, don rage ƙazantattun ƙarfe da ƙurar C, girman barbashi na tushen SiC yakamata a sarrafa shi gabaɗaya zuwa diamita na ƙasa da μm 200, kuma ƙimar girma kada ta wuce ~ 0.4 mm / h don kula da jinkirin canja wurin taro da kuma ware masu iyo. C kura. Ƙarfe da ƙurar C suna haifar da lalacewar manyan lu'ulu'u na SiC, waɗanda sune manyan cikas ga saurin haɓakar SiC ta hanyar PVT.

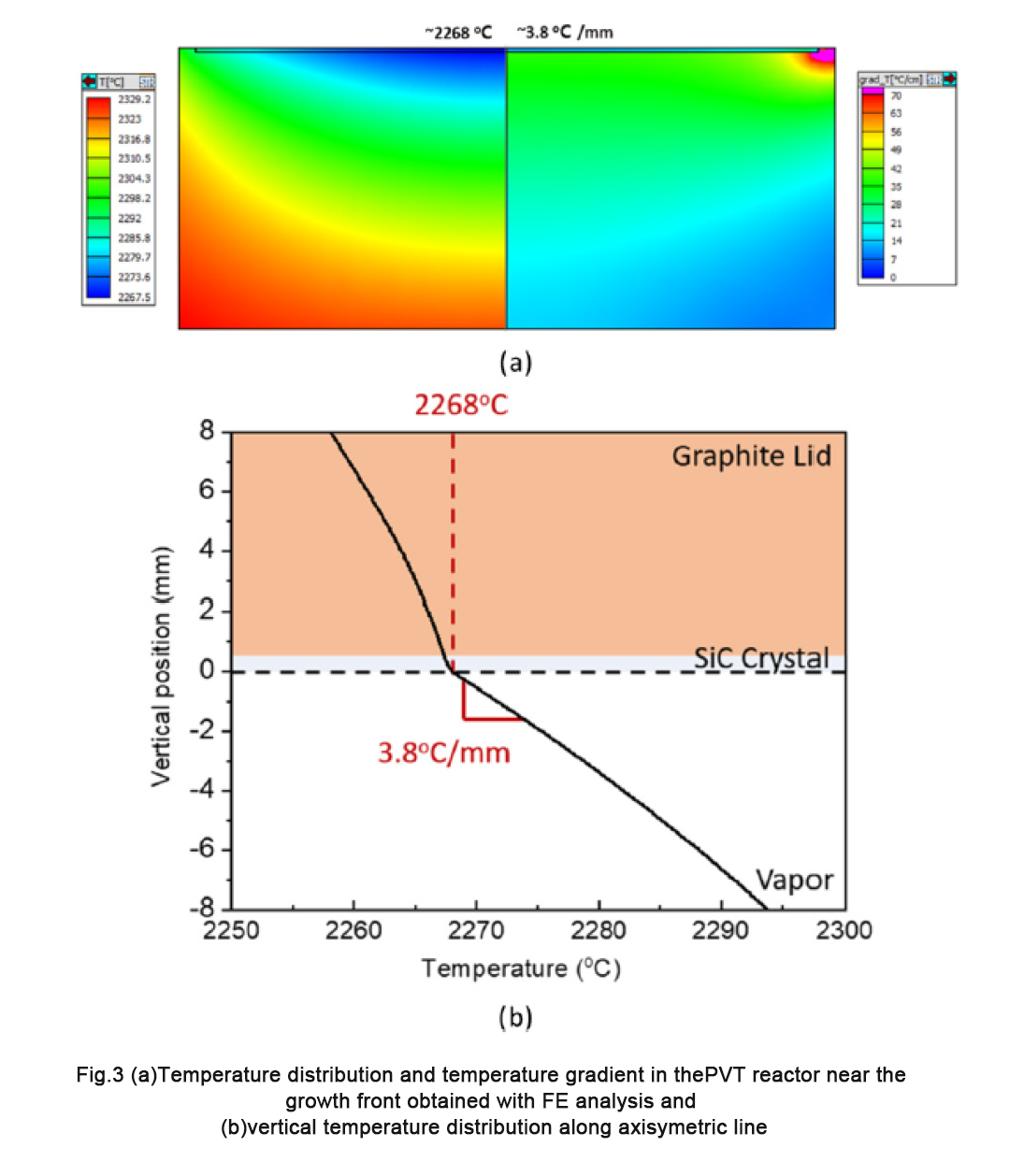

A cikin wannan binciken, an yi amfani da tushen CVD-SiC da aka murƙushe ba tare da ƙananan barbashi ba, kawar da ƙurar C mai iyo a ƙarƙashin ƙaƙƙarfan canja wurin taro. Don haka, an tsara tsarin yanki na thermal ta amfani da hanyar PVT na tushen simintin multiphysics don cimma saurin ci gaban SiC, kuma ana nuna rarraba yanayin zafin jiki da ƙarancin zafin jiki a cikin Hoto 3a.

Hoto 3: (a) Rarraba zafin jiki da yanayin zafin jiki kusa da ci gaban gaban PVT reactor da aka samu ta hanyar bincike mai iyaka, da (b) rarraba zafin jiki a tsaye tare da layin axisymmetric.

Idan aka kwatanta da saitunan yankin thermal na yau da kullun don haɓaka lu'ulu'u na SiC a ƙimar girma na 0.3 zuwa 0.8 mm/h ƙarƙashin ƙaramin zafin jiki na ƙasa da 1 ° C/mm, saitunan yankin thermal a cikin wannan binciken suna da ɗan ƙaramin zafin jiki na ∼ 3.8C/mm a yanayin girma na ~2268°C. Matsakaicin ƙimar zafin jiki a cikin wannan binciken yana kwatankwacin saurin haɓakar SiC a ƙimar 2.4 mm/h ta amfani da hanyar HTCVD, inda aka saita girman zafin jiki zuwa ~ 14 ° C/mm. Daga madaidaicin rarraba zafin jiki da aka nuna a cikin Hoto 3b, mun tabbatar da cewa babu wani juzu'in zafin jiki wanda zai iya haifar da polycrystals kusa da ci gaban gaba, kamar yadda aka bayyana a cikin wallafe-wallafe.

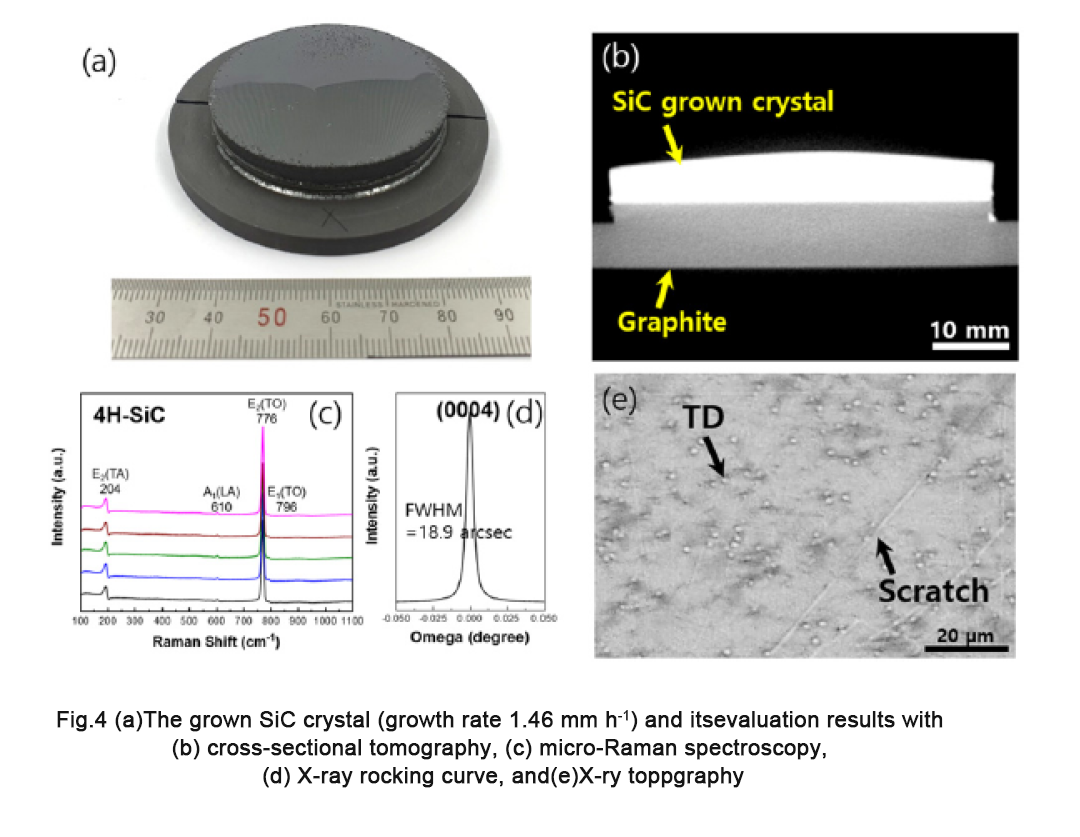

Yin amfani da tsarin PVT, an girma lu'ulu'u na SiC daga tushen CVD-SiC don 4 hours, kamar yadda aka nuna a cikin Figures 2 da 3. Ana nuna alamar girma na SiC crystal girma daga SiC mai girma a cikin Hoto 4a. Kauri da ƙimar girma na kristal SiC da aka nuna a Hoto 4a sune 5.84 mm da 1.46 mm/h, bi da bi. An bincika tasirin tushen SiC akan inganci, nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in halitta, da kuma tsabtar kristal mai girma na SiC wanda aka nuna a cikin Hoto 4a, kamar yadda aka nuna a cikin Figures 4b-e. Hoton zane-zane na giciye a cikin Hoto na 4b yana nuna cewa girman kristal ya kasance mai siffa mai ma'ana saboda yanayin girma mara kyau. Duk da haka, micro-Raman spectroscopy a cikin Hoto 4c ya gano crystal girma a matsayin lokaci guda na 4H-SiC ba tare da wani nau'i na polytype ba. Ƙimar FWHM na kololuwar (0004) da aka samu daga bincike-bincike na girgizar motsi na X-ray ya kasance 18.9 arc seconds, kuma yana tabbatar da ingantaccen ingancin crystal.

Hoto 4: (a) Girman SiC crystal (yawan girma na 1.46 mm / h) da sakamakon kimantawa tare da (b) zane-zane na giciye, (c) micro-Raman spectroscopy, (d) X-ray rocking curve, da ( e) Hoton hoto na X-ray.

Hoto na 4e yana nuna hoton hoto na farin katako na X-ray wanda ke gano ɓarna da ɓarkewar zaren a cikin walƙiya mai gogewa na kristal mai girma. An auna girman girman kristal da aka girma don zama ~ 3000 ea/cm², dan kadan sama da rarrabuwar kristal iri, wanda shine ~ 2000 ea/cm². An tabbatar da girman lu'ulu'u yana da ƙarancin ƙarancin rarrabuwar kawuna, kwatankwacin ingancin kristal na wafers na kasuwanci. Abin sha'awa, an sami saurin haɓakar lu'ulu'u na SiC ta amfani da hanyar PVT tare da murƙushe tushen CVD-SiC a ƙarƙashin babban yanayin zafin jiki. Ƙididdigar B, Al, da N a cikin kristal girma sun kasance 2.18 × 10¹⁶, 7.61 × 10¹⁵, da 1.98 × 10¹⁹ atoms/cm³, bi da bi. Matsakaicin P a cikin crystal girma yana ƙasa da iyakar ganowa (<1.0 × 10¹⁴ atom/cm³). Matsakaicin ƙazanta sun yi ƙasa sosai don masu ɗaukar kaya, ban da N, wanda aka yi da gangan a lokacin aikin CVD.

Ko da yake ci gaban crystal a cikin wannan binciken ya kasance ƙananan la'akari da samfurori na kasuwanci, ƙaddamar da nasara na ci gaban SiC mai sauri tare da kyakkyawar inganci ta amfani da tushen CVD-SiC ta hanyar PVT yana da tasiri mai mahimmanci. Tun da tushen CVD-SiC, duk da kyawawan kaddarorin su, suna da tsada-tsari ta hanyar sake yin amfani da kayan da aka jefar, muna sa ran yin amfani da su da yawa azaman tushen SiC mai ban sha'awa don maye gurbin tushen foda na SiC. Don amfani da tushen CVD-SiC don saurin girma na SiC, ana buƙatar haɓaka rarraba zafin jiki a cikin tsarin PVT, yana gabatar da ƙarin tambayoyi don bincike na gaba.

Kammalawa

A cikin wannan binciken, an sami nasarar nunin saurin girma na SiC crystal ta amfani da bulogin CVD-SiC da aka murƙushe ƙarƙashin yanayin gradient mai zafi ta hanyar hanyar PVT. Abin sha'awa, an sami saurin haɓakar lu'ulu'u na SiC ta hanyar maye gurbin tushen SiC tare da hanyar PVT. Ana sa ran wannan hanyar za ta ƙara haɓaka ingantaccen samarwa na SiC guda lu'ulu'u, a ƙarshe rage farashin naúrar SiC substrates da haɓaka yawan amfani da na'urori masu ƙarfi masu ƙarfi.

Lokacin aikawa: Jul-19-2024