Bayanin Tsarin Semiconductor

Tsarin semiconductor da farko ya ƙunshi amfani da microfabrication da fasahar fina-finai don haɗa kwakwalwan kwamfuta da sauran abubuwa a cikin yankuna daban-daban, kamar maɓalli da firam. Wannan yana sauƙaƙe fitar da tashoshi na gubar da ƙyalli tare da matsakaicin rufin filastik don samar da haɗaɗɗiyar gabaɗaya, wanda aka gabatar a matsayin tsari mai girma uku, a ƙarshe yana kammala aikin marufi na semiconductor. Manufar tsarin semiconductor shima ya shafi ma'anar kunkuntar marufi na guntu na semiconductor. Daga fa'idar hangen nesa, yana nufin injiniyan marufi, wanda ya haɗa da haɗawa da daidaitawa zuwa ƙasa, daidaita kayan aikin lantarki masu dacewa, da gina cikakken tsarin tare da ingantaccen aiki mai ƙarfi.

Tsarin Marufi na Semiconductor

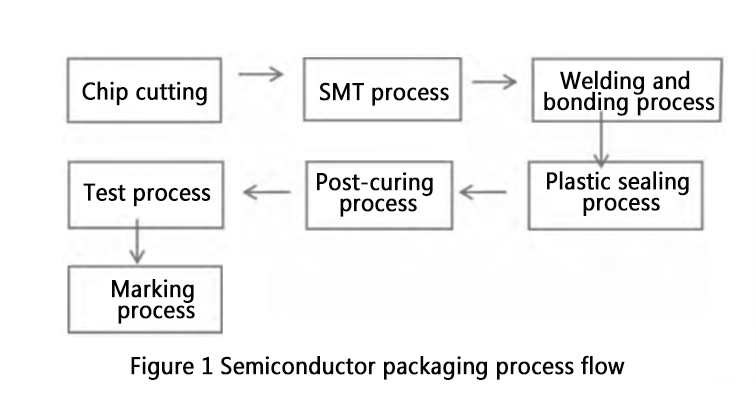

Tsarin marufi na semiconductor ya haɗa da ayyuka da yawa, kamar yadda aka kwatanta a cikin Hoto 1. Kowane tsari yana da ƙayyadaddun buƙatu da ayyukan aiki da ke da alaƙa, yana buƙatar cikakken bincike yayin mataki mai amfani. Takamammen abun ciki shine kamar haka:

1. Yankan guntu

A cikin tsarin marufi na semiconductor, yankan guntu ya ƙunshi yankan wafers ɗin siliki cikin kwakwalwan kwamfuta guda ɗaya da cire tarkacen silicon da sauri don hana cikas ga aiki na gaba da sarrafa inganci.

2. Chip Dutsen

Tsarin hawan guntu yana mai da hankali kan guje wa lalacewar da'ira yayin niƙa wafer ta amfani da Layer na fim mai kariya, koyaushe yana jaddada amincin kewaye.

3. Tsarin haɗin waya

Sarrafa ingancin tsarin haɗin waya ya haɗa da yin amfani da nau'ikan wayoyi na gwal daban-daban don haɗa pad ɗin haɗin guntu tare da firam ɗin, tabbatar da guntu na iya haɗawa zuwa da'irori na waje da kuma kiyaye amincin tsari gabaɗaya. Yawanci, ana amfani da wayoyi na gwal da aka yi amfani da su da kuma wayoyi na gwal da aka saka.

Doped Gold Wayoyi: Nau'in sun haɗa da GS, GW, da TS, masu dacewa da manyan baka (GS:> 250 μm), matsakaici-high arc (GW: 200-300 μm), da matsakaici-ƙananan baka (TS: 100-200). μm) haɗin gwiwa bi da bi.

Alloyed Gold Wayoyi: Nau'in sun haɗa da AG2 da AG3, masu dacewa da haɗin gwiwar ƙananan baka (70-100 μm).

Zaɓuɓɓukan diamita na waɗannan wayoyi suna daga 0.013 mm zuwa 0.070 mm. Zaɓin nau'in da ya dace da diamita bisa ga buƙatun aiki da ƙa'idodi yana da mahimmanci don sarrafa inganci.

4. Tsarin Molding

Babban kewayawa a cikin abubuwan gyare-gyaren ya ƙunshi encapsulation. Sarrafa ingancin tsarin gyare-gyare yana kare abubuwan da aka gyara, musamman daga sojojin waje da ke haifar da nau'i daban-daban na lalacewa. Wannan ya ƙunshi cikakken bincike na abubuwan da aka gyara na zahiri.

A halin yanzu ana amfani da manyan hanyoyi guda uku: fakitin yumbu, fakitin filastik, da marufi na gargajiya. Gudanar da rabon kowane nau'in marufi yana da mahimmanci don biyan buƙatun samar da guntu na duniya. A yayin aiwatar da aikin, ana buƙatar ingantattun damar iyawa, kamar preheating guntu da firam ɗin jagora kafin a haɗa su tare da resin epoxy, gyare-gyare, da warkewar bayan-mold.

5. Tsari Bayan-Curing

Bayan tsarin gyare-gyare, ana buƙatar magani bayan warkewa, yana mai da hankali kan cire duk wani abu da ya wuce kima a kusa da tsari ko kunshin. Kula da inganci yana da mahimmanci don gujewa shafar ingancin tsari gaba ɗaya da bayyanar.

6.Tsarin Gwaji

Da zarar an kammala matakan da suka gabata, dole ne a gwada ingancin aikin gaba ɗaya ta amfani da fasahar gwaji da kayan aiki na ci gaba. Wannan matakin ya ƙunshi cikakken rikodin bayanai, yana mai da hankali kan ko guntu yana aiki akai-akai dangane da matakin aikinsa. Ganin tsadar kayan aikin gwaji, yana da mahimmanci don kula da inganci a duk matakan samarwa, gami da duba gani da gwajin aikin lantarki.

Gwajin Ayyukan Lantarki: Wannan ya haɗa da gwada haɗaɗɗun da'irori ta amfani da kayan gwaji ta atomatik da tabbatar da an haɗa kowace da'ira da kyau don gwajin lantarki.

Duban Kayayyakin gani: Masu fasaha suna amfani da na'urori masu ƙima don bincikar ƙwanƙwasa da aka gama da su don tabbatar da cewa ba su da lahani kuma sun dace da ingancin marufi na semiconductor.

7. Tsarin Alama

Tsarin yin alama ya haɗa da canja wurin kwakwalwan kwamfuta da aka gwada zuwa ɗakin ajiyar da aka kammala don aiki na ƙarshe, dubawa mai inganci, marufi, da jigilar kaya. Wannan tsari ya ƙunshi manyan matakai guda uku:

1) Electroplating: Bayan samar da jagororin, ana amfani da wani abu mai hana lalata don hana oxidation da lalata. Ana amfani da fasahar saka kayan lantarki galibi tunda yawancin jagororin da aka yi da tin.

2) Lankwasawa: Sannan ana siffanta jagororin da aka sarrafa, tare da haɗaɗɗen ɗigon kewayawa da aka sanya a cikin kayan aikin samar da gubar, sarrafa sifar jagorar (nau'in J ko L) da fakitin da aka ɗora sama.

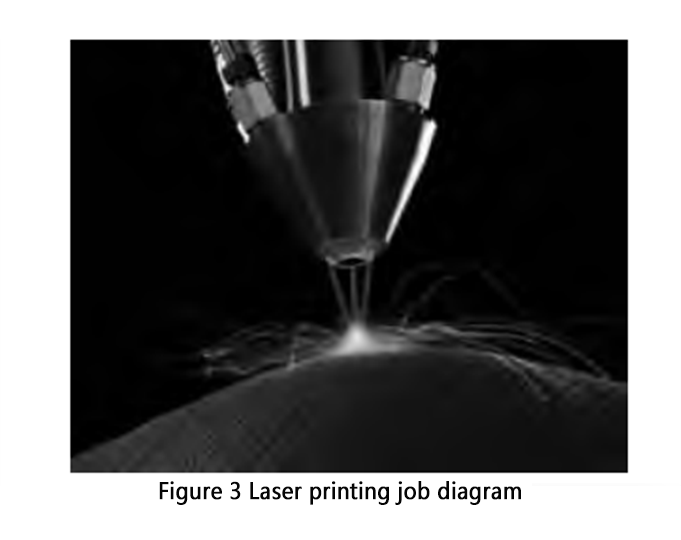

3) Buga Laser: A ƙarshe, samfuran da aka ƙirƙira ana buga su tare da ƙira, wanda ke zama alama ta musamman don tsarin marufi na semiconductor, kamar yadda aka kwatanta a hoto na 3.

Kalubale da Shawarwari

Nazarin tafiyar matakai na marufi na semiconductor yana farawa da bayyani na fasahar semiconductor don fahimtar ƙa'idodinta. Na gaba, yin la'akari da kwararar tsarin marufi yana nufin tabbatar da kulawa mai kyau yayin aiki, ta amfani da ingantaccen kulawa don guje wa al'amuran yau da kullun. A cikin mahallin ci gaban zamani, gano ƙalubalen a cikin hanyoyin tattara kayan aikin semiconductor yana da mahimmanci. Ana ba da shawarar mayar da hankali kan abubuwan sarrafawa mai inganci, da sarrafa mahimman mahimman bayanai don haɓaka ingancin tsari yadda ya kamata.

Yin nazari daga hangen nesa mai inganci, akwai ƙalubale masu mahimmanci yayin aiwatarwa saboda yawancin matakai tare da takamaiman abun ciki da buƙatu, kowannensu yana rinjayar ɗayan. Ana buƙatar kulawa mai ƙarfi yayin ayyuka masu amfani. Ta hanyar ɗaukar halin aiki mai mahimmanci da amfani da fasahar ci gaba, za a iya inganta ingancin tsarin marufi na semiconductor da matakan fasaha, tabbatar da ingantaccen ingantaccen aikace-aikacen da samun fa'idodi gabaɗaya.(kamar yadda aka nuna a cikin Hoto 3).

Lokacin aikawa: Mayu-22-2024