Silicon carbide (SiC)abu yana da fa'ida na faffadan bandgap, high thermal conductivity, high m m rushewar filin ƙarfi, da kuma cikakken electron drift gudu, sa shi sosai m a cikin semiconductor masana'antu filin. SiC guda lu'ulu'u ana samarwa gabaɗaya ta hanyar jigilar tururi ta jiki (PVT). Matakan ƙayyadaddun matakan wannan hanya sun haɗa da sanya SiC foda a kasan ginshiƙan graphite da kuma sanya crystal iri na SiC a saman crucible. graphitecrucibleyana mai zafi zuwa ƙananan zafin jiki na SiC, yana haifar da SiC foda don lalata cikin abubuwa masu tururi kamar Si vapor, Si2C, da SiC2. Ƙarƙashin tasirin zafin zafin jiki na axial, waɗannan abubuwan da aka vaporized suna ƙarƙashin saman crucible kuma suna daɗaɗɗa a saman kristal iri na SiC, suna crystallizing cikin SiC guda lu'ulu'u.

A halin yanzu, diamita na kristal iri da ake amfani dashi a cikiSiC guda crystal girmayana buƙatar daidaita maƙasudin diamita na crystal. A lokacin girma, kristal iri yana daidaitawa akan mai riƙe iri a saman ƙugiya ta amfani da m. Duk da haka, wannan hanyar gyara kristal iri na iya haifar da al'amura irin su ɓoyayyiya a cikin maɗauri saboda dalilai kamar daidaitaccen saman mai riƙe da iri da daidaiton murfin manne, wanda zai iya haifar da lahani mara kyau na hexagonal. Waɗannan sun haɗa da haɓaka shimfiɗar farantin graphite, haɓaka daidaitaccen kauri na manne, da ƙara madaidaicin madauri mai sassauƙa. Duk da waɗannan ƙoƙarce-ƙoƙarce, har yanzu akwai al'amura game da yawa na mannen Layer, kuma akwai haɗarin rarrabuwar kristal iri. Ta hanyar ɗaukar hanyar haɗin gwiwawaferzuwa graphite takarda da lissafta shi a saman crucible, da yawa daga cikin m Layer za a iya inganta, da detachment na wafer za a iya hana.

1. Tsarin Gwaji:

Wafers da aka yi amfani da su a gwajin ana samun su ta kasuwanci6-inch N-type SiC wafers. Ana amfani da Photoresist ta amfani da abin rufe fuska. Ana samun mannewa ta amfani da tanderun da aka ƙera iri-iri.

1.1 Tsare-tsare Tsararren Tsari:

A halin yanzu, ana iya raba tsare-tsaren mannewa na SiC ɗin crystal zuwa kashi biyu: nau'in mannewa da nau'in dakatarwa.

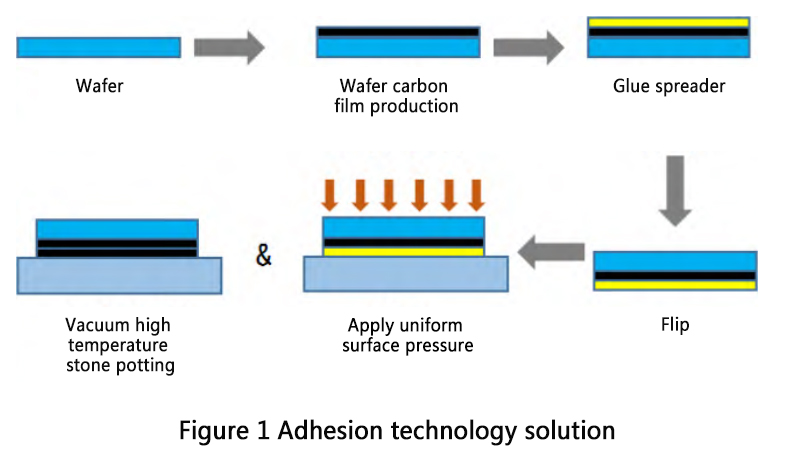

Tsarin Nau'in Adhesive (Hoto 1): Wannan ya haɗa da haɗawa daSiC waferzuwa farantin graphite tare da takarda na graphite a matsayin mai ɗaukar hoto don kawar da rata tsakaninSiC waferda farantin graphite. A cikin ainihin samarwa, ƙarfin haɗin kai tsakanin takarda graphite da farantin graphite yana da rauni, yana haifar da ƙaddamar da ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar cuta.

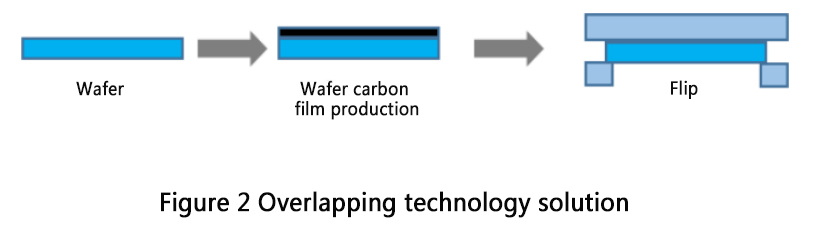

Tsarin Nau'in Dakatarwa (Hoto 2): Yawanci, an ƙirƙiri fim ɗin carbon mai yawa akan saman haɗin gwiwa na wafer SiC ta amfani da carbonization na manne ko hanyoyin sutura. TheSiC wafersai a manne a tsakanin faranti guda biyu na graphite kuma a sanya su a saman faifan graphite, yana tabbatar da kwanciyar hankali yayin da fim ɗin carbon ke kare wafer. Duk da haka, ƙirƙirar fim ɗin carbon ta hanyar sutura yana da tsada kuma bai dace da samar da masana'antu ba. Hanyar manne carbonization yana haifar da ingancin fim ɗin carbon da ba daidai ba, yana sa ya zama da wahala a sami fim ɗin carbon mai ƙarancin gaske tare da mannewa mai ƙarfi. Bugu da ƙari, manne faranti na graphite yana rage ingantaccen wurin girma na wafer ta hanyar toshe ɓangaren saman sa.

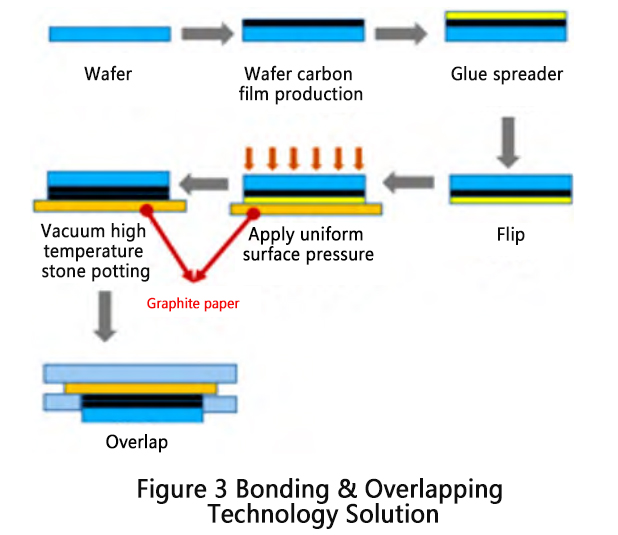

Dangane da tsare-tsare biyu na sama, an ƙaddamar da sabon tsarin mannewa da haɗawa (Hoto 3):

An ƙirƙiri wani ɗan ƙaramin fim ɗin carbon mai ɗanɗano a saman haɗin gwiwar SiC wafer ta amfani da hanyar manne carbonization, yana tabbatar da cewa babu babban haske a ƙarƙashin haske.

Wafern SiC da aka rufe da fim ɗin carbon an haɗa shi da takarda graphite, tare da haɗin haɗin gwiwa shine gefen fim ɗin carbon. Ya kamata Layer manne ya bayyana iri ɗaya baki a ƙarƙashin haske.

Takardar graphite tana manne da faranti mai graphite kuma an dakatar da ita sama da faifan faifan hoto don haɓakar kristal.

1.2 Manne:

A danko na photoresist muhimmanci rinjayar da fim kauri uniformity. A daidai wannan saurin juyi, ƙananan danko yana haifar da ɓangarorin sirara da ƙarin nau'ikan fina-finai na mannewa. Saboda haka, an zaɓi ɗan ƙaramin danko mai ɗaukar hoto a cikin buƙatun aikace-aikacen.

A lokacin gwajin, an gano cewa danko na carbonizing m yana rinjayar ƙarfin haɗin kai tsakanin fim ɗin carbon da wafer. Babban danko yana sa ya zama da wahala a yi amfani da su ta hanyar amfani da suturar juzu'i, yayin da ƙarancin danko yana haifar da raunin haɗin gwiwa, wanda ke haifar da fashewar fim ɗin carbon yayin matakan haɗin gwiwa na gaba saboda kwararar mannewa da matsa lamba na waje. Ta hanyar bincike na gwaji, an ƙaddara dankon abin da ake amfani da shi na carbonizing ya zama 100mPa·s, kuma an saita danƙon mannewa zuwa 25mPa·s.

1.3 Kayan aiki:

Tsarin ƙirƙirar fim ɗin carbon akan wafer na SiC ya haɗa da carbonizing Layer m akan SiC wafer surface, wanda dole ne a yi shi a cikin wani yanayi mara kyau ko kariyar argon. Sakamakon gwaji ya nuna cewa yanayin da ke da kariya ta argon ya fi dacewa da ƙirƙirar fim ɗin carbon fiye da yanayin yanayi mai yawa. Idan an yi amfani da mahalli, matakin injin ya zama ≤1 Pa.

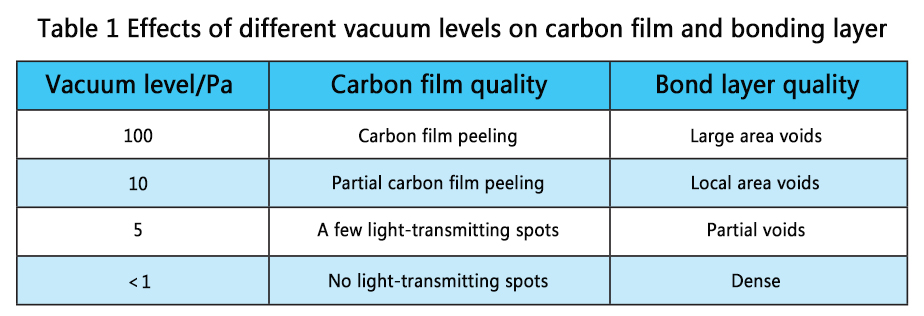

Tsarin haɗin kristal iri na SiC ya haɗa da haɗa wafern SiC zuwa farantin graphite. Yin la'akari da tasirin iskar oxygen a kan kayan graphite a yanayin zafi mai zafi, wannan tsari yana buƙatar gudanar da shi a ƙarƙashin yanayi mara kyau. An yi nazarin tasirin matakan vacuum daban-daban akan mannen Layer. Ana nuna sakamakon gwajin a cikin Teburin 1. Ana iya ganin cewa a ƙarƙashin ƙananan yanayi, kwayoyin oxygen a cikin iska ba a cire su gaba daya ba, wanda ke haifar da ƙananan yadudduka masu mannewa. Lokacin da matakin injin ya kasance ƙasa da 10 Pa, tasirin iskar oxygen a kan mannen Layer yana raguwa sosai. Lokacin da matakin injin yana ƙasa da 1 Pa, an kawar da tasirin lalata gaba ɗaya.

Lokacin aikawa: Juni-11-2024