1.Game da Haɗin Kai

1.1 Tunani da haihuwar hadedde da'irori

Integrated Circuit (IC): yana nufin na'urar da ke haɗa na'urori masu aiki kamar transistor da diodes tare da abubuwan da ba za a iya amfani da su ba kamar su resistors da capacitors ta hanyar takamaiman dabarun sarrafawa.

Da'ira ko tsarin da aka “haɗe” akan na’ura mai kwakwalwa (kamar silicon ko mahadi irin su gallium arsenide) wafer bisa ga wasu hanyoyin haɗin da’ira sannan kuma an haɗa su cikin harsashi don yin takamaiman ayyuka.

A cikin 1958, Jack Kilby, wanda ke da alhakin ƙarancin kayan aikin lantarki a Texas Instruments (TI), ya ba da shawarar ra'ayin haɗaɗɗun da'irori:

"Tunda duk abubuwan da aka gyara kamar capacitors, resistors, transistors, da dai sauransu ana iya yin su daga abu daya, na yi tunanin zai yiwu a sanya su a kan wani yanki na semiconductor sannan a haɗa su don samar da cikakkiyar kewaye."

A ranar 12 ga Satumba da 19 ga Satumba, 1958, Kilby ya kammala ƙera da nunin oscillator da faɗakarwa na lokaci-lokaci, bi da bi, alamar haihuwar haɗaɗɗiyar da'ira.

A cikin 2000, Kilby ya sami lambar yabo ta Nobel a Physics. Kwamitin bayar da lambar yabo ta Nobel ya taɓa yin sharhi cewa Kilby “ya kafa harsashin fasahar sadarwa ta zamani.”

Hoton da ke ƙasa yana nuna Kilby da haɗe-haɗen haƙƙin mallaka:

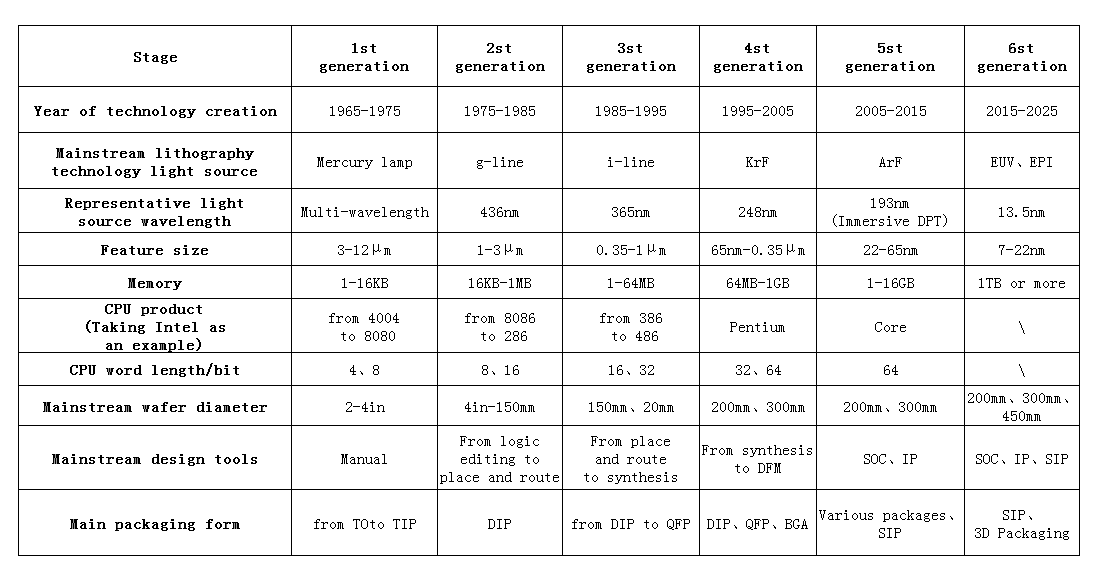

1.2 Haɓaka fasahar masana'antar semiconductor

Hoto mai zuwa yana nuna matakan haɓaka fasahar masana'antar semiconductor:

1.3 Hadakar Sarkar masana'antar kewayawa

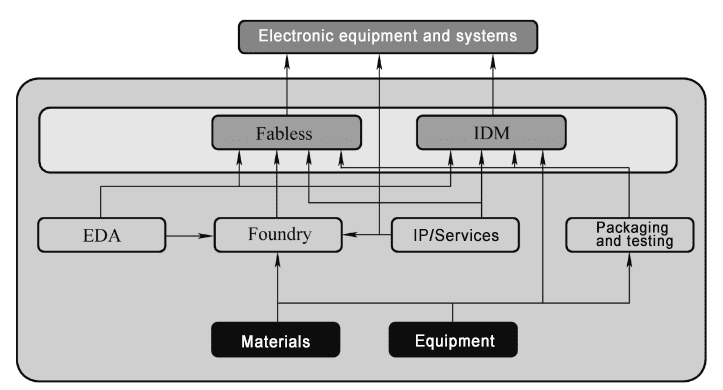

Abubuwan da ke tattare da sarkar masana'antar semiconductor (yafi hadedde da'irori, gami da na'urori masu hankali) ana nuna su a cikin adadi na sama:

- Fabless: Kamfanin da ke kera kayayyaki ba tare da layin samarwa ba.

- IDM: Haɗe-haɗen na'ura mai ƙira, haɗaɗɗen na'ura mai ƙira;

- IP: Mai sana'anta module;

- EDA: Kayan Wutar Lantarki ta atomatik, ƙirar ƙirar lantarki, kamfanin ya fi samar da kayan aikin ƙira;

- Kafa; Wafer foundry, samar da guntu masana'antu ayyuka;

- Marufi da gwada kamfanonin kafa masana'antu: galibi hidimar Fables da IDM;

- Kayayyaki da kamfanonin kayan aiki na musamman: galibi suna ba da kayan da ake buƙata da kayan aiki don kamfanonin kera guntu.

Babban samfuran da aka samar ta amfani da fasahar semiconductor hadedde ne da'irori da na'urori masu hankali.

Babban samfuran haɗin gwiwar da'irori sun haɗa da:

- Ƙa'idar Ƙirar Ƙarfafa Ƙwararru (ASSP);

- Unit Microprocessor (MPU);

- Ƙwaƙwalwar ajiya

- Aikace-aikacen Specific Integrated Circuit (ASIC);

- Analog Circuit;

- Da'irar dabaru na gabaɗaya (Logical Circuit).

Babban samfuran na'urori masu hankali na semiconductor sun haɗa da:

- Diode;

- transistor;

- Na'urar Wutar Lantarki;

- Babban Na'urar Wutar Lantarki;

- Na'urar Microwave;

- Optoelectronics;

- Na'urar Sensor (Sensor).

2. Haɗe-haɗen Tsarin Ƙirƙirar Ƙira

2.1 Chip Manufacturing

Dubban ko ma dubun-dubatar takamaiman kwakwalwan kwamfuta ana iya yin su lokaci guda akan wafer siliki. Yawan kwakwalwan kwamfuta a kan wafer silicon ya dogara da nau'in samfuri da girman kowane guntu.

Silicon wafers yawanci ake kira substrates. Diamita na wafers silicon yana ƙaruwa tsawon shekaru, daga ƙasa da inch 1 a farkon zuwa inci 12 da aka saba amfani da shi (kimanin 300 mm) yanzu, kuma yana jurewa zuwa inci 14 ko inci 15.

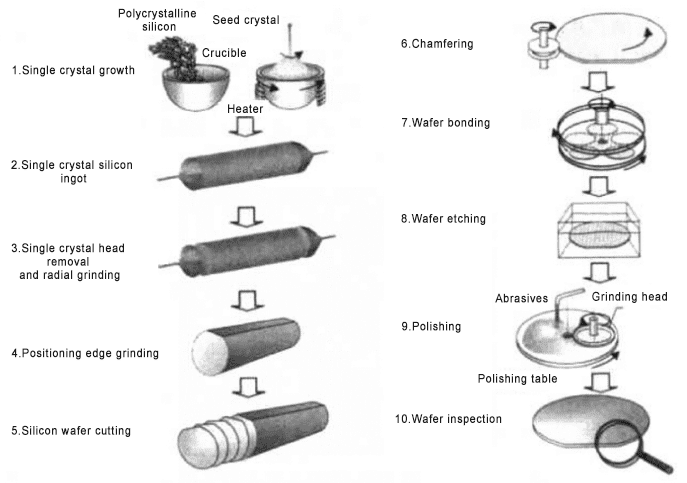

Gabaɗaya masana'antar guntu ta kasu zuwa matakai biyar: shirye-shiryen wafer silicon, masana'antar wafer silicon, gwajin guntu/ɗaukarwa, taro da marufi, da gwaji na ƙarshe.

(1)

Silicon wafer shiri:

Don yin albarkatun kasa, ana fitar da siliki daga yashi kuma an tsarkake shi. Wani tsari na musamman yana samar da ingots silicon na diamita mai dacewa. Daga nan sai a yanka ingots zuwa siraran siliki don yin microchips.

An shirya wafers zuwa takamaiman ƙayyadaddun bayanai, kamar buƙatun gefen rajista da matakan gurɓatawa.

(2)Silicon wafer masana'anta:

Hakanan an san shi da masana'antar guntu, wafer siliki na siliki ya isa masana'antar masana'antar siliki sannan ya wuce ta tsaftacewa daban-daban, ƙirƙirar fina-finai, hotunan hoto, etching da matakan doping. Wafer siliki da aka sarrafa yana da cikakken saiti na haɗe-haɗe da da'irori wanda aka kwaikwayi har abada akan wafer silicon.

(3)Gwaji da zaɓin wafern siliki:

Bayan an gama masana'antar wafer silicon, ana aika wafern siliki zuwa wurin gwaji/nau'i, inda ake bincika kwakwalwan kwamfuta guda ɗaya kuma ana gwada su ta hanyar lantarki. Ana daidaita kwakwalwan kwamfuta masu karɓuwa da waɗanda ba za a yarda da su ba, kuma ana yiwa guntu masu lahani alama.

(4)Majalisa da marufi:

Bayan gwajin wafer / rarrabuwa, wafers suna shigar da taro da matakin marufi don haɗa kwakwalwan mutum ɗaya a cikin fakitin bututu mai karewa. Gefen baya na wafer yana ƙasa don rage kauri daga cikin substrate.

Ana makala wani fim mai kauri mai kauri a bayan kowane wafer, sannan a yi amfani da tsintsiya mai tsinin lu'u-lu'u don raba guntuwar da ke kan kowane wafer tare da layin magatakarda a gefen gaba.

Fim ɗin filastik a bayan wafer siliki yana kiyaye guntun siliki daga faɗuwa. A cikin masana'antar taro, ana danna guntu masu kyau ko fitar da su don samar da kunshin taro. Daga baya, guntu an rufe shi a cikin filastik ko harsashi na yumbu.

(5)Gwajin karshe:

Don tabbatar da aikin guntu, ana gwada kowace haɗaɗɗiyar da'irar don saduwa da buƙatun sigar sigar lantarki da muhalli na masana'anta. Bayan gwaji na ƙarshe, ana aika guntu zuwa abokin ciniki don haɗuwa a cikin keɓe wuri.

2.2 Rarraba Tsari

Haɗe-haɗen hanyoyin kera da'ira gabaɗaya an raba su zuwa:

Gaba-gaba: Tsarin gaba-gaba gabaɗaya yana nufin tsarin kera na'urori irin su transistor, galibi gami da hanyoyin samar da keɓewa, tsarin ƙofa, tushe da magudanar ruwa, ramukan lamba, da sauransu.

Ƙarshen baya: Tsarin baya-baya yana nufin samuwar layukan haɗin gwiwa waɗanda za su iya watsa siginar lantarki zuwa na'urori daban-daban akan guntu, galibi sun haɗa da matakai irin su dielectric deposition tsakanin layin haɗin gwiwa, samuwar layin ƙarfe, da samuwar kushin gubar.

Tsakanin mataki: Domin inganta aikin transistor, ƙananan fasahar fasaha bayan 45nm / 28nm suna amfani da high-k gate dielectrics da metal ƙofa tafiyar matakai, da kuma ƙara maye gurbin ƙofa tafiyar matakai da na gida interconnect tafiyar matakai bayan transistor tushen da magudanar tsarin da aka shirya. Wadannan matakai suna tsakanin tsarin gaba-gaba da tsarin baya, kuma ba a amfani da su a cikin tsarin al'ada, don haka ana kiran su matakan tsakiya.

Yawancin lokaci, tsarin shirye-shiryen ramin lamba shine layin rarraba tsakanin tsarin gaba-gaba da tsarin baya-baya.

Ramin lamba: wani rami da aka zana a tsaye a cikin wafern siliki don haɗa layin haɗin ƙarfe na farko-Layer da na'urar da ke ƙasa. An cika shi da ƙarfe kamar tungsten kuma ana amfani dashi don jagorantar na'urar lantarki zuwa layin haɗin gwiwa na karfe.

Ta hanyar Hole: Ita ce hanyar haɗin kai tsakanin layuka biyu masu maƙwabtaka na layin haɗin ƙarfe na ƙarfe, wanda ke a cikin dielectric Layer tsakanin sassan ƙarfe biyu, kuma gabaɗaya yana cike da karafa kamar tagulla.

A cikin ma'ana mai faɗi:

Tsarin gaba-gaba: A cikin ma'ana mai faɗi, haɗaɗɗen kera da'ira ya kamata kuma ya haɗa da gwaji, marufi da sauran matakai. Idan aka kwatanta da gwaji da marufi, kayan aiki da masana'antun haɗin gwiwar haɗin gwiwa su ne ɓangaren farko na masana'antar keɓaɓɓiyar haɗaɗɗun da'ira, tare da ake magana da su azaman matakai na gaba;

Tsarin baya-baya: Gwaji da marufi ana kiran su tsarin baya-baya.

3. Shafi

SMIF: Matsakaicin Interface Mechanical

AMHS: Tsarin Hannun Kayan Aiki Na atomatik

OHT: Canja wurin Hoist na Sama

FOUP: Fayil ɗin Buɗewar Gaba, Na Musamman zuwa 12 inch (300mm) wafers

Mafi mahimmanci,Semicera na iya bayarwasassa graphite, taushi / m ji,silicon carbide sassa, CVD silicon carbide sassa, kumaSiC/TaC rufaffiyar sassatare da cikakken tsari na semiconductor a cikin kwanaki 30.Muna sa ran zama abokin tarayya na dogon lokaci a kasar Sin.

Lokacin aikawa: Agusta-15-2024