Dubi Daya

A cikin tsarin masana'antar da'ira mai haɗaka, photolithography shine ainihin tsari wanda ke ƙayyade matakin haɗin kai na haɗaɗɗun da'irori. Ayyukan wannan tsari shine watsawa da aminci da canja wurin bayanan hoto mai hoto daga abin rufe fuska (wanda ake kira abin rufe fuska) zuwa madaidaicin abu na semiconductor.

Babban ka'idar aikin photolithography shine yin amfani da amsawar photochemical na photoresist mai rufi a saman mashin don yin rikodin ƙirar kewaye akan abin rufe fuska, don haka cimma manufar canja wurin haɗaɗɗun ƙirar kewaye daga ƙira zuwa ƙasa.

Ainihin tsari na photolithography

Na farko, ana amfani da photoresist a kan farfajiyar ƙasa ta amfani da na'ura mai sutura;

Sa'an nan kuma, ana amfani da na'ura na photolithography don fallasa substrate mai rufi tare da photoresisist, kuma ana amfani da tsarin amsawa na photochemical don yin rikodin bayanan abin rufe fuska da injin photolithography ke watsawa, yana kammala watsa aminci, canja wuri da kwafi na abin rufe fuska ga substrate;

A ƙarshe, ana amfani da mai haɓakawa don haɓaka ɓangarorin da aka fallasa don cirewa (ko riƙe) mai ɗaukar hoto wanda ke fuskantar halayen hoto bayan fallasa.

Tsarin daukar hoto na biyu

Don canja wurin ƙirar da'irar da aka ƙera akan abin rufe fuska zuwa wafer siliki, dole ne a fara aiwatar da canja wuri ta hanyar hanyar bayyanawa, sannan kuma dole ne a sami tsarin siliki ta hanyar etching.

Tun da hasken yankin aiwatar da hoto na photolithography yana amfani da tushen hasken rawaya wanda kayan aikin hoto ba su da hankali, ana kuma kiran shi yankin hasken rawaya.

An fara amfani da Photolithography a cikin masana'antar bugawa kuma shine babbar fasaha don masana'antar PCB ta farko. Tun daga 1950s, photolithography a hankali ya zama fasaha na yau da kullun don canja wurin tsari a masana'antar IC.

Maɓallin maɓalli na tsarin lithography sun haɗa da ƙuduri, hankali, daidaito mai rufi, ƙimar lahani, da sauransu.

Abu mafi mahimmanci a cikin tsarin hotunan hoto shine photoresisist, wanda shine abu mai ɗaukar hoto. Tunda hankalin mai ɗaukar hoto ya dogara da tsayin daka na tushen haske, ana buƙatar kayan aikin hoto daban-daban don matakan hoto kamar layin g/i, 248nm KrF, da 193nm ArF.

Babban tsari na tsari na hoto na al'ada ya ƙunshi matakai biyar

:

-Tsarin fim ɗin tushe;

-Amfani photoresist da gasa mai laushi;

- daidaitawa, fallasa da yin burodi bayan fallasa;

- Ci gaba da fim mai wuya;

-Ganowar ci gaba.

(1)Base fim shiri: galibi tsaftacewa da bushewa. Saboda duk wani gurɓataccen abu zai raunana mannewa tsakanin photoresist da wafer, tsaftacewa sosai zai iya inganta mannewa tsakanin wafer da photoresist.

(2)Rubutun hoto: Ana samun wannan ta hanyar jujjuya wafer siliki. Daban-daban masu ɗaukar hoto suna buƙatar sigogin tsari daban-daban, gami da saurin juyawa, kauri mai ɗaukar hoto, da zafin jiki.

Yin burodi mai laushi: Yin burodi na iya inganta mannewa tsakanin photoresist da wafer silicon, kazalika da daidaituwar kauri na photoresist, wanda ke da fa'ida don daidaitaccen sarrafa ma'aunin geometric na tsarin etching na gaba.

(3)Daidaitawa da fallasa: Daidaitawa da bayyanawa sune matakai mafi mahimmanci a cikin tsarin daukar hoto. Suna nufin daidaita tsarin abin rufe fuska tare da tsarin da ake da shi akan wafer (ko ƙirar ƙirar gaba), sannan kuma haskaka shi da takamaiman haske. Ƙarfin haske yana kunna abubuwan da aka haɗa da hotuna a cikin hoton hoto, ta haka ne ke canja wurin abin rufe fuska ga mai ɗaukar hoto.

Kayan aikin da aka yi amfani da su don daidaitawa da nunawa shine na'ura mai daukar hoto, wanda shine mafi tsada guda ɗaya na kayan aiki a cikin dukkanin tsarin masana'antu da aka haɗa. Matsayin fasaha na na'ura na photolithography yana wakiltar matakin ci gaba na dukan layin samarwa.

Yin burodi bayan fallasa: yana nufin ɗan gajeren yin burodi bayan fallasa, wanda ke da tasiri daban-daban fiye da a cikin zurfin ultraviolet photoresists da na al'ada i-line photoresists.

Don zurfin ultraviolet photoresist, bayan-bayyana yin burodi yana kawar da abubuwan kariya a cikin photoresisist, yana barin mai ɗaukar hoto ya narke a cikin mai haɓakawa, don haka yin burodi bayan fallasa ya zama dole;

Ga al'ada i-line photoresists, bayan fallasa yin burodi zai iya inganta adhesion na photoresist da kuma rage tsaye tãguwar ruwa (tsaye tãguwar ruwa zai yi wani mummunan tasiri a kan gefen ilimin halittar jiki na photoresist).

(4)Haɓaka fim ɗin mai wuya: ta yin amfani da mai haɓakawa don narkar da ɓangaren mai narkewa na photoresist (tabbatacce photoresist) bayan fallasa, da kuma nuna daidai tsarin abin rufe fuska tare da tsarin hoto.

Mahimman ma'auni na tsarin ci gaba sun haɗa da zafin jiki na ci gaba da lokaci, ƙaddamarwa da ƙaddamarwa da ƙaddamarwa, tsaftacewa, da dai sauransu Ta hanyar daidaita ma'auni masu dacewa a cikin ci gaba, za a iya ƙara yawan bambance-bambance a cikin raguwa tsakanin sassan da aka fallasa da kuma ba a bayyana ba na photoresisist, ta haka ne. samun tasirin ci gaban da ake so.

Hardening kuma aka sani da hardening yin burodi, wanda shine aiwatar da cire sauran sauran ƙarfi, developer, ruwa da sauran ba dole ba saura aka gyara a cikin ɓullo da photoresist ta dumama da evaporating su, don inganta mannewa na photoresist zuwa silicon substrate. da etching juriya na photoresist.

Yanayin zafin jiki na tsarin hardening ya bambanta dangane da nau'ikan photoresists daban-daban da hanyoyin hardening. Jigon shi ne cewa tsarin photoresist ba ya lalacewa kuma ya kamata a sanya mai daukar hoto da ƙarfi sosai.

(5)Binciken ci gaba: Wannan shine don bincika lahani a cikin ƙirar photoresist bayan haɓakawa. Yawancin lokaci, ana amfani da fasahar tantance hoto don bincika tsarin guntu ta atomatik bayan haɓakawa da kwatanta shi da daidaitaccen tsari mara lahani da aka rigaya aka adana. Idan aka sami wani bambanci, ana ɗauka a matsayin mai lahani.

Idan adadin lahani ya wuce wani ƙima, ana yanke hukuncin wafer siliki ya gaza gwajin haɓakawa kuma ana iya soke shi ko sake yin aiki kamar yadda ya dace.

A cikin haɗe-haɗen tsarin kera da'ira, yawancin matakai ba za su iya jurewa ba, kuma photolithography na ɗaya daga cikin tsirarun hanyoyin da za a iya sake yin aiki.

Photomask guda uku da kayan hana daukar hoto

3.1 Photomask

Mashin hoto, wanda kuma aka sani da abin rufe fuska na photolithography, babban ƙwararren ƙwararren masani ne da ake amfani da shi a cikin tsarin ɗaukar hoto na haɗaɗɗen wafer da'ira.

Tsarin masana'anta na photomask shine canza bayanan shimfidar wuri na asali da ake buƙata don masana'antar wafer da aka ƙera ta haɗaɗɗun injiniyoyin ƙirar kewaye zuwa tsarin bayanan da za a iya gane su ta hanyar janareta na ƙirar laser ko na'urar fiddawa ta lantarki ta hanyar sarrafa bayanan rufe fuska, ta yadda za a iya fallasa ta ta kayan aikin da ke sama a kan abin da ake amfani da su na photomask mai rufi tare da kayan aiki mai mahimmanci; sa'an nan kuma ana sarrafa shi ta hanyar matakai masu yawa irin su haɓakawa da haɓakawa don gyara tsarin a kan kayan da ake amfani da su; a ƙarshe, ana dubawa, gyara, tsaftacewa, da kuma sanya fim ɗin don samar da samfurin abin rufe fuska kuma a kai shi ga masana'anta da aka haɗa don amfani.

3.2 Mai daukar hoto

Photoresist, wanda kuma aka sani da photoresist, abu ne mai ɗaukar hoto. Abubuwan da ke ɗauke da hotuna a cikinsa za su sami sauye-sauyen sinadarai a ƙarƙashin isar da hasken wuta, wanda hakan zai haifar da canje-canje a cikin adadin narkarwar. Babban aikinsa shine don canja wurin tsari akan abin rufe fuska zuwa wani abu kamar wafer.

Ƙa'idar aiki na photoresist: Na farko, an rufe photoresist a kan substrate kuma an riga an yi gasa don cire sauran ƙarfi;

Abu na biyu, abin rufe fuska yana fallasa zuwa haske, yana haifar da abubuwan da ke tattare da daukar hoto a cikin sashin da aka fallasa don yin maganin sinadarai;

Sa'an nan kuma, ana yin gasa bayan fallasa;

A ƙarshe, an narkar da mai ɗaukar hoto ta hanyar haɓakawa (don tabbataccen hoto, yankin da aka fallasa yana narkar da; don mummunan hoto, yankin da ba a bayyana shi ba yana narkar da shi), don haka fahimtar canja wurin tsarin da'ira mai haɗawa daga abin rufe fuska zuwa mashin.

Abubuwan da ake amfani da su na photoresist galibi sun haɗa da guduro mai ƙirƙirar fim, ɓangaren hotuna, abubuwan ƙari da sauran ƙarfi.

Daga cikin su, ana amfani da resin mai yin fim don samar da kayan aikin injiniya da juriya na etching; ɓangarorin masu ɗaukar hoto yana jure canjin sinadarai a ƙarƙashin haske, yana haifar da canje-canje a cikin adadin narkar da;

Abubuwan da aka gano sun haɗa da rini, masu haɓaka danko, da dai sauransu, waɗanda ake amfani da su don inganta aikin photoresisist; Ana amfani da kaushi don narkar da abubuwan da aka gyara kuma a haɗa su daidai.

Ana iya raba masu ɗaukar hoto a halin yanzu a cikin fa'ida mai fa'ida zuwa ga masu ɗaukar hoto na gargajiya da haɓaka masu haɓaka photoresists bisa ga tsarin ɗaukar hoto na photochemical, kuma ana iya raba su zuwa ultraviolet, zurfin ultraviolet, matsananciyar ultraviolet, katako na lantarki, ion katako da masu ɗaukar hoto na X-ray bisa ga tsawon zangon hotuna.

Kayan aikin daukar hoto hudu

Fasahar daukar hoto ta tafi ta hanyar ci gaba na lamba / kusanci lithography, hangen nesa lithography, mataki-da-maimaita lithography, scanning lithography, immersion lithography, da EUV lithography.

4.1 Na'urar Lithography na lamba / kusanci

Fasahar lithography ta bayyana a cikin 1960s kuma an yi amfani da ita sosai a cikin 1970s. Ita ce babbar hanyar lithography a zamanin ƙanana na haɗaɗɗun da'irori kuma an yi amfani da ita musamman don samar da haɗaɗɗun da'irori tare da girman fasalin sama da 5μm.

A cikin na'urar lithography na lamba/kusanci, yawanci ana sanya wafer akan matsayi kwance da hannu da hannu da kuma aikin juyawa. Mai aiki yana amfani da na'ura mai ƙima na filin don lura da matsayin abin rufe fuska da wafer, kuma da hannu yana sarrafa matsayin tebur don daidaita abin rufe fuska da wafer. Bayan wafer da abin rufe fuska suna daidaitawa, za a danna su biyu tare domin abin rufe fuska yana cikin hulɗa kai tsaye tare da mai ɗaukar hoto a saman wafer.

Bayan cire makasudin microscope, wafer da abin rufe fuska ana matsar da su zuwa tebur mai fallasa don fallasa. Hasken da fitilar mercury ke fitarwa yana haɗuwa kuma yayi daidai da abin rufe fuska ta ruwan tabarau. Tun da abin rufe fuska yana cikin hulɗar kai tsaye tare da Layer na photoresist a kan wafer, ana canza tsarin mask din zuwa Layer na photoresist a wani rabo na 1: 1 bayan bayyanarwa.

Kayan aikin lithography na tuntuɓar shine mafi sauƙi kuma mafi tattalin arziƙin kayan aikin lithography na gani, kuma yana iya cimma buƙatuwar girman girman fasalin juzu'in micron, don haka har yanzu ana amfani da shi a cikin ƙananan ƙirar samfura da binciken dakin gwaje-gwaje. A cikin manyan haɗe-haɗe da kera da'ira, an ƙaddamar da fasahar lithography na kusanci don guje wa haɓakar farashin lithography wanda ke haifar da hulɗa kai tsaye tsakanin abin rufe fuska da wafer.

An yi amfani da lithography na kusanci sosai a cikin shekarun 1970s a lokacin daɗaɗɗen haɗaɗɗun ƙananan sikelin da farkon zamanin haɗaɗɗun ma'auni. Ba kamar lithography na lamba ba, abin rufe fuska a cikin lithography na kusanci baya cikin hulɗa kai tsaye tare da mai ɗaukar hoto akan wafer, amma an bar rata da ke cike da nitrogen. Maskurin yana yawo a kan nitrogen, kuma girman rata tsakanin abin rufe fuska da wafer an ƙaddara ta matsa lamba na nitrogen.

Tun da babu wata hulɗar kai tsaye tsakanin wafer da abin rufe fuska a cikin lithography na kusanci, an rage lahani da aka gabatar a lokacin aikin lithography, ta haka ne rage asarar abin rufe fuska da inganta yawan amfanin gona. A cikin lithography na kusanci, rata tsakanin wafer da abin rufe fuska yana sanya wafer a cikin yankin Fresnel diffraction. Kasancewar diffraction yana iyakance ƙarin haɓaka ƙudurin kusancin kayan aikin lithography, don haka wannan fasaha ta fi dacewa da samar da hanyoyin haɗin gwiwa tare da girman fasalin sama da 3μm.

4.2 Stepper da Maimaitawa

Stepper yana ɗaya daga cikin kayan aiki mafi mahimmanci a cikin tarihin wafer lithography, wanda ya inganta tsarin lithography na sub-micron zuwa samar da taro. Matsakaicin yana amfani da filin fayyace na yau da kullun na 22mm × 22mm da ruwan tabarau na tsinkayar gani tare da raguwar rabo na 5:1 ko 4:1 don canja wurin tsari akan abin rufe fuska zuwa wafer.

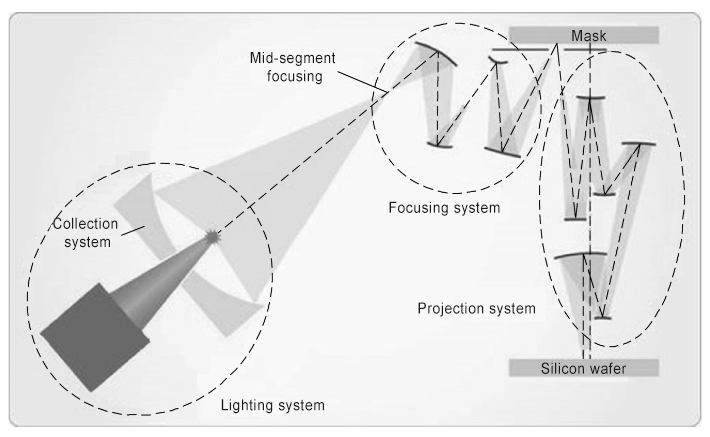

Na'urar lithography na mataki-da-maimaitawa gabaɗaya ta ƙunshi tsarin watsa shirye-shirye, tsarin tsarin aikin aiki, tsarin tsarin mashin fuska, tsarin mayar da hankali / matakin daidaitawa, tsarin daidaitawa, babban tsarin firam, tsarin canja wurin wafer, tsarin canja wurin abin rufe fuska. , tsarin tsarin lantarki, da tsarin tsarin software.

Tsarin aiki na yau da kullun na na'urar lithography mataki-da-maimaitawa shine kamar haka:

Na farko, wafer mai rufi tare da photoresis yana canjawa wuri zuwa teburin aikin ta amfani da tsarin canja wurin wafer, kuma abin rufe fuska da za a fallasa an canza shi zuwa teburin abin rufe fuska ta amfani da tsarin canja wurin abin rufe fuska;

Sa'an nan, tsarin yana amfani da mayar da hankali / matakin subsystem don yin Multi-aya tsawo auna a kan wafer a kan workpiece mataki don samun bayanai kamar tsawo da karkatar kwana na surface na wafer da za a fallasa, sabõda haka, da daukan hotuna yankin na Ana iya sarrafa wafer koyaushe a cikin zurfin zurfin haƙiƙanin tsinkaya yayin aiwatar da fallasa;Daga baya, tsarin yana amfani da tsarin daidaitawa don daidaita abin rufe fuska da wafer ta yadda yayin aiwatar da fallasa daidaiton matsayi na hoton abin rufe fuska da canja wurin ƙirar wafer koyaushe yana cikin buƙatun mai rufi.

A ƙarshe, aikin mataki-da-bayyana duk saman wafer an kammala bisa ga hanyar da aka tsara don gane aikin canja wurin tsari.

Mataki na gaba da na'urar lithography na na'urar daukar hotan takardu ta dogara ne akan tsarin aiki na asali na sama, inganta haɓakawa → fallasa zuwa dubawa → fallasa, da mayar da hankali / matakin → daidaitawa → fallasa akan ƙirar matakai biyu don aunawa (mayar da hankali / matakin → daidaitawa) da dubawa fallasa a layi daya.

Idan aka kwatanta da na'ura-da-scan lithography inji, mataki-da-maimaita lithography inji ba ya bukatar don cimma synchronous juyi scanning na abin rufe fuska da wafer, kuma baya bukatar scanning abin rufe fuska da tsarin synchronous scanning tsarin. Sabili da haka, tsarin yana da sauƙi mai sauƙi, farashin yana da ƙananan ƙananan, kuma aikin yana dogara.

Bayan fasahar IC ta shiga 0.25μm, aikace-aikace na mataki-da-maimaita lithography ya fara raguwa saboda fa'idodin lithography na mataki-da-scan a cikin bincika girman filin fiddawa da daidaiton fallasa. A halin yanzu, sabon mataki-da-maimaita lithography wanda Nikon ya samar yana da fage mai fa'ida a tsaye wanda ya kai girman na matakin-da-scan lithography, kuma yana iya sarrafa fiye da wafers 200 a cikin sa'a, tare da ingantaccen samarwa sosai. A halin yanzu ana amfani da irin wannan nau'in injin lithography don kera yadudduka na IC marasa mahimmanci.

4.3 Scanner na Stepper

An fara amfani da lithography na mataki-da-scan a cikin 1990s. Ta hanyar daidaita maɓuɓɓuka masu haske daban-daban, fasahar mataki-da-scan na iya tallafawa nau'ikan fasahar tsari daban-daban, daga 365nm, 248nm, 193nm nutsewa zuwa lithography na EUV. Ba kamar mataki-da-maimaita lithography, da filin daya-filaye na mataki-da-scan lithography rungumi dabi'ar kuzarin kawo cikas, wato, abin rufe fuska farantin kammala Ana dubawa motsi synchronously dangane da wafer; bayan an gama bayyanar filin na yanzu, ana ɗaukar wafer ta matakin aikin aikin kuma ya taka zuwa matsayin filin dubawa na gaba, kuma ana ci gaba da bayyanawa akai-akai; maimaita bayyanar mataki-da-scan sau da yawa har sai an fallasa dukkan filayen wafer.

Ta hanyar daidaita nau'ikan hanyoyin haske daban-daban (kamar i-line, KrF, ArF), na'urar daukar hotan takardu na iya tallafawa kusan dukkanin nodes na fasaha na tsarin gaba-gaba na semiconductor. Hanyoyin CMOS na tushen silicon na yau da kullun sun karɓi matakan-scanners a cikin adadi mai yawa tun kumburin 0.18μm; matsananci ultraviolet (EUV) lithography inji a halin yanzu amfani a aiwatar nodes kasa 7nm kuma amfani stepper-scanning. Bayan gyare-gyaren daidaitawa na ɗan lokaci, stepper-scanner kuma zai iya tallafawa bincike da haɓakawa da samar da yawancin hanyoyin da ba na siliki ba kamar MEMS, na'urorin wuta, da na'urorin RF.

Manyan masana'antun na matakan-da-scan tsinkayar lithography inji sun hada da ASML (Netherland), Nikon (Japan), Canon (Japan) da SMEE (China). ASML ta ƙaddamar da tsarin TWINSCAN na injin lithography na mataki-da-scan a cikin 2001. Yana ɗaukar tsarin gine-ginen matakai biyu, wanda zai iya inganta ƙimar kayan aiki yadda ya kamata kuma ya zama injin lithography mafi girma da aka fi amfani dashi.

4.4 Immersion Lithography

Ana iya gani daga tsarin Rayleigh cewa, lokacin da tsayin daka ya kasance baya canzawa, hanya mai mahimmanci don ƙara inganta ƙudurin hoto shine ƙara yawan buɗewar tsarin hoto. Don ƙudurin hoto da ke ƙasa da 45nm kuma mafi girma, hanyar bayyanar bushewar ArF ba za ta iya ƙara biyan buƙatun ba (saboda tana goyan bayan matsakaicin ƙudurin hoto na 65nm), don haka ya zama dole a gabatar da hanyar lithography nutsewa. A cikin fasahar lithography na al'ada, matsakaicin tsakanin ruwan tabarau da mai ɗaukar hoto shine iska, yayin da fasahar lithography ta nutsewa ta maye gurbin matsakaicin iska da ruwa (yawanci ultrapure ruwa tare da ma'anar refractive na 1.44).

A haƙiƙa, fasahar lithography na nutsewa tana amfani da gajarta tsawon lokacin hasken hasken bayan haske ya ratsa cikin matsakaicin ruwa don inganta ƙuduri, kuma gajarta rabo shine maƙasudin refractive na matsakaicin ruwa. Kodayake injin lithography na nutsewa nau'in injin lithography ne na mataki-da-scan, kuma tsarin tsarin kayan aikinsa bai canza ba, gyare-gyare ne da haɓaka injin lithography na mataki-da-scan na ArF saboda ƙaddamar da mahimman fasahar da ke da alaƙa. zuwa nutsewa.

Amfanin lithography na nutsewa shine cewa, saboda haɓakar haɓakar lambobi na tsarin, ƙarfin ƙudurin hoto na injin lithography na stepper-scanner yana inganta, wanda zai iya biyan buƙatun aiwatar da ƙudurin hoto a ƙasa 45nm.

Tun da injin lithography na nutsewa har yanzu yana amfani da tushen hasken ArF, an tabbatar da ci gaba da aiwatarwa, adana farashin R&D na tushen haske, kayan aiki da tsari. A kan wannan, haɗe tare da zane-zane da yawa da fasahar lithography, za a iya amfani da injin lithography na nutsewa a nodes na 22nm da ƙasa. Kafin a sanya injin lithography na EUV bisa hukuma a cikin samarwa da yawa, an yi amfani da injin lithography na nutsewa sosai kuma yana iya biyan buƙatun tsari na kumburin 7nm. Koyaya, saboda shigar da ruwa mai nutsewa, wahalar injiniyan kayan aikin kanta ya karu sosai.

Maɓallin fasaharsa sun haɗa da samar da ruwa mai nutsewa da fasahar dawo da ruwa, fasahar kiyaye ruwa mai nitsewa, gurɓataccen gurɓataccen iska da fasahar sarrafa lahani, haɓakawa da kiyaye manyan manyan lambobi masu tsinkayar tsinkayar tsinkayar rami, da fasahar gano ingancin hoto a ƙarƙashin yanayin nutsewa.

A halin yanzu, injunan lithography na ArFi na kasuwanci galibi kamfanoni biyu ne ke samarwa, wato ASML na Netherlands da Nikon na Japan. Daga cikinsu, farashin ASML NXT1980 Di guda ya kai kusan Yuro miliyan 80.

4.5 Matsanancin Na'urar Lithography na Ultraviolet

Domin inganta ƙuduri na photolithography, da daukan hotuna za a kara taqaitaccen daftarin aiki bayan da eximer haske tushen, da kuma matsananci ultraviolet haske da tsawon na 10 zuwa 14 nm aka gabatar a matsayin fallasa tushen haske. Tsawon tsayin matsanancin hasken ultraviolet gajere ne, kuma tsarin gani na gani da za a iya amfani da shi galibi yana kunshe da masu nuna fina-finai da yawa kamar Mo/Si ko Mo/Be.

Daga cikin su, madaidaicin ma'auni na fim ɗin Mo/Si multilayer a cikin kewayon tsayin 13.0 zuwa 13.5nm shine kusan 70%, kuma matsakaicin matsakaicin ka'idar Mo/Be multilayer fim a ɗan gajeren zangon 11.1nm shine kusan 80%. Ko da yake nuni na Mo/Be multilayer fina-finan fina-finai ya fi girma, Be yana da guba sosai, don haka an yi watsi da bincike kan irin waɗannan kayan lokacin haɓaka fasahar lithography na EUV.Fasahar lithography ta EUV na yanzu tana amfani da fim ɗin Mo/Si multilayer, kuma an ƙaddara tsawon tsayinsa na 13.5nm.

Matsakaicin madaidaicin hasken ultraviolet yana amfani da fasahar plasma da aka samar da Laser (LPP), wanda ke amfani da Laser masu ƙarfi don tada zafin narke Sn plasma don fitar da haske. Na dogon lokaci, iko da samun tushen hasken sun kasance ƙullun da ke hana ingantattun injunan lithography na EUV. Ta hanyar babban amplifier ikon oscillator, fasaha na plasma (PP) mai tsinkaya da fasahar tsabtace madubi a cikin wurin, an inganta ƙarfi da kwanciyar hankali na tushen hasken EUV.

Injin lithography na EUV galibi ya ƙunshi tsarin ƙasa kamar tushen haske, walƙiya, ruwan tabarau na haƙiƙa, matakin aiki, matakin abin rufe fuska, daidaitawar wafer, mai da hankali / matakin daidaitawa, watsa abin rufe fuska, watsa wafer, da firam ɗin injin. Bayan wucewa ta tsarin haskakawa wanda ya ƙunshi nau'i-nau'i masu launi masu yawa, matsanancin hasken ultraviolet yana haskakawa akan abin rufe fuska. Hasken da abin rufe fuska ke nunawa yana shiga cikin tsarin hoto gabaɗaya na hangen nesa wanda ya ƙunshi jerin abubuwan nuni, kuma a ƙarshe an nuna hoton abin rufe fuska a saman wafer a cikin yanayi mara kyau.

Filin fiɗaɗɗen ra'ayi da filin hoto na injin lithography na EUV duka biyu ne masu siffa-arc, kuma ana amfani da hanyar sikirin mataki-mataki don cimma cikakkiyar bayyanar wafer don haɓaka ƙimar fitarwa. Na'urar lithography mafi ci gaba ta ASML ta NXE ta EUV tana amfani da tushen haske mai fallasa tare da tsawon 13.5nm, abin rufe fuska (6° abin da ya faru), tsarin haƙiƙanin ragi na 4x tare da tsarin madubi 6 (NA = 0.33), a filin duban ra'ayi na 26mm × 33mm, da kuma yanayin fallasa iska.

Idan aka kwatanta da injunan lithography na nutsewa, ƙudurin ɗaukar hoto guda ɗaya na injunan lithography na EUV ta amfani da matsanancin hasken ultraviolet an inganta sosai, wanda zai iya guje wa hadadden tsari da ake buƙata don ɗaukar hoto da yawa don ƙirƙirar zane mai ƙima. A halin yanzu, ƙudurin nuni guda ɗaya na injin lithography na NXE 3400B tare da buɗaɗɗen lamba na 0.33 ya kai 13nm, ƙimar fitarwa ya kai 125 guda / h.

Don saduwa da buƙatun ƙarin haɓaka Dokar Moore, a nan gaba, injunan lithography na EUV tare da buɗaɗɗen lamba na 0.5 za su ɗauki tsarin haƙiƙa na haƙiƙa tare da toshe hasken tsakiya, ta amfani da haɓakar asymmetric na sau 0.25/0.125, da Za a rage filin ra'ayi na dubawa daga 26m × 33mm zuwa 26mm × 16.5mm, kuma ƙudurin ɗaukar hoto guda ɗaya zai iya. kasa da 8nm.

——————————————————————————————————————————————————— ———————————

Semicera na iya bayarwasassa graphite, taushi / m ji, silicon carbide sassa, CVD silicon carbide sassa, kumaSiC/TaC rufaffiyar sassatare da cikakken tsari na semiconductor a cikin kwanaki 30.

Idan kuna sha'awar samfuran semiconductor na sama,don Allah kar a yi shakka a tuntube mu a farkon lokaci.

Lambar waya: +86-13373889683

WhatsApp: +86-15957878134

Email: sales01@semi-cera.com

Lokacin aikawa: Agusta-31-2024