Gabatarwa Daya

Etching a cikin haɗe-haɗen tsarin kera da'ira ya kasu zuwa:

- rigar etching;

- bushewar etching.

A cikin kwanakin farko, an yi amfani da rigar etching sosai, amma saboda iyakancewar sa a cikin sarrafa faɗin layi da jagorancin etching, yawancin matakai bayan 3μm suna amfani da bushewar etching. Ana amfani da rigar etching kawai don cire wasu kayan yadudduka na musamman da sauran tsaftataccen ruwa.

Dry etching yana nufin tsarin yin amfani da etchants sinadarai na gas don amsawa tare da kayan da ke kan wafer don cire ɓangaren kayan da za a cire da kuma samar da samfurori masu canzawa, waɗanda aka ciro daga ɗakin amsawa. Etchant yawanci ana samar da shi kai tsaye ko a kaikaice daga plasma na iskar gas, don haka bushe etching kuma ana kiransa etching plasma.

1.1 Plasma

Plasma iskar gas ne a cikin yanayi mai rauni wanda aka samu ta hanyar fitar da iskar gas mai haske a ƙarƙashin aikin filin lantarki na waje (kamar samar da wutar lantarki ta mitar rediyo). Ya haɗa da electrons, ions da tsaka-tsaki masu aiki. Daga cikin su, barbashi masu aiki zasu iya amsawa kai tsaye ta hanyar sinadarai tare da kayan da aka ƙera don cimma etching, amma wannan sinadari mai tsafta yawanci yana faruwa ne kawai a cikin ƙaramin adadin kayan kuma ba jagora bane; lokacin da ions suna da wani kuzari, ana iya siffanta su ta hanyar sputters na zahiri kai tsaye, amma yawan etching na wannan tsantsar dauki na zahiri yana da ƙarancin gaske kuma zaɓin yana da rauni sosai.

Yawancin etching na plasma an kammala tare da sa hannu na barbashi masu aiki da ions a lokaci guda. A cikin wannan tsari, ion bombardment yana da ayyuka biyu. Na daya shine a lalata makamin atomic a saman kayan da aka kwaikwayi, ta yadda za a kara yawan abin da barbashi na tsaka tsaki ke amsawa da shi; ɗayan shine a ƙwanƙwasa samfuran amsawa da aka ajiye akan yanayin amsawa don sauƙaƙe abubuwan da ake buƙata don tuntuɓar saman kayan da aka kwaikwayi, ta yadda etching ya ci gaba.

Samfuran amsawa da aka ajiye akan bangon bangon sifarin ba za a iya cire su da kyau ta hanyar bam na ion ba, don haka toshe etching na gefen bangon da ƙirƙirar etching anisotropic.

Tsarin etching na biyu

2.1 Rigar Etching da Tsaftacewa

Rigar etching ɗaya ce daga cikin fasahar farko da aka yi amfani da ita wajen kera haɗe-haɗe. Ko da yake mafi yawan rigar etching matakai an maye gurbinsu da anisotropic bushe etching saboda isotropic etching, har yanzu yana taka muhimmiyar rawa wajen tsaftacewa maras muhimmanci yadudduka na girma girma. Musamman a cikin etching na oxide cire sharan gona da epidermal tsiri, ya fi tasiri da kuma tattalin arziki fiye da bushe etching.

Abubuwan rigar etching sun haɗa da silicon oxide, silicon nitride, silicon crystal silicon da polycrystalline silicon. Wet etching na silicon oxide yawanci yana amfani da hydrofluoric acid (HF) a matsayin babban mai ɗaukar sinadarai. Don haɓaka zaɓin zaɓi, ana amfani da dilute hydrofluoric acid buffered ta ammonium fluoride a cikin tsari. Don kiyaye kwanciyar hankali na ƙimar pH, ana iya ƙara ƙaramin adadin acid mai ƙarfi ko wasu abubuwa. Doped silicon oxide ya fi sauƙi lalata fiye da siliki oxide mai tsabta. Ana amfani da rigar sinadarai da ake amfani da su musamman don cire photoresist da abin rufe fuska mai wuya (silicon nitride). Hot phosphoric acid (H3PO4) shine babban ruwan sinadari da ake amfani dashi don rigar sinadarai don cire siliki nitride, kuma yana da zaɓi mai kyau don silicon oxide.

Tsabtace rigar yana kama da rigar etching, kuma galibi yana kawar da gurɓataccen abu a saman wafern silicon ta hanyar halayen sinadarai, gami da barbashi, kwayoyin halitta, karafa da oxides. Babban rigar tsaftacewa shine hanyar sinadarai rigar. Ko da yake tsaftace bushewa na iya maye gurbin yawancin hanyoyin tsabtace rigar, babu wata hanyar da za ta iya maye gurbin tsabtace rigar gaba daya.

Abubuwan da aka saba amfani da su don tsabtace rigar sun haɗa da sulfuric acid, hydrochloric acid, hydrofluoric acid, phosphoric acid, hydrogen peroxide, ammonium hydroxide, ammonium fluoride, da sauransu. samar da maganin tsaftacewa, kamar SC1, SC2, DHF, BHF, da dai sauransu.

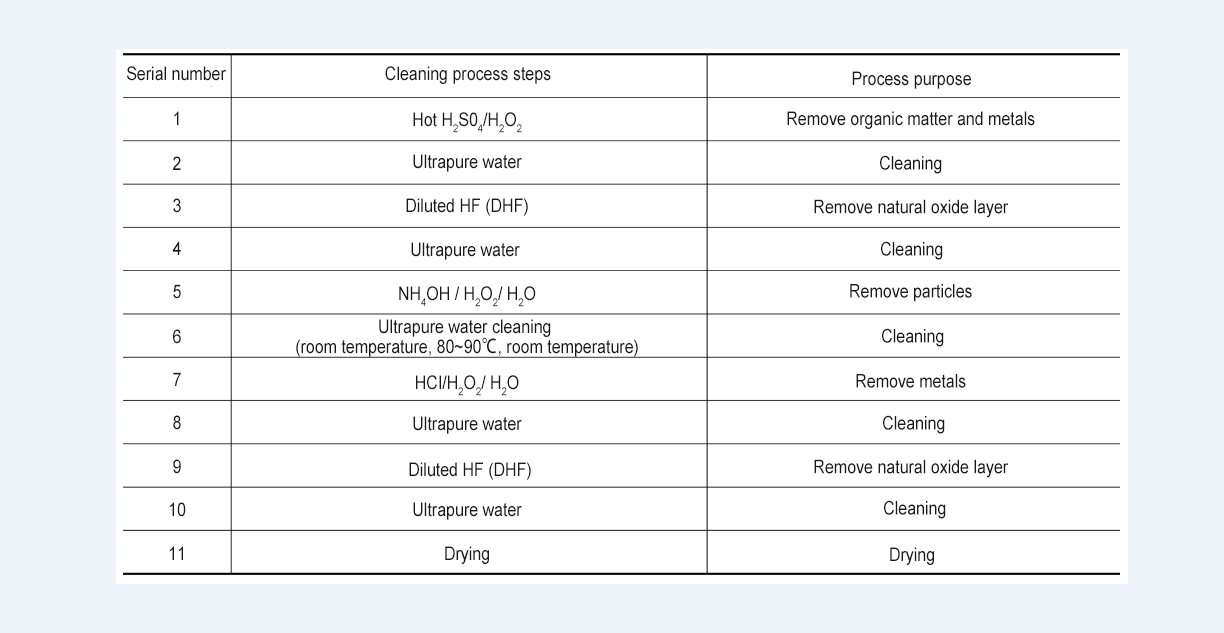

Ana amfani da tsaftacewa sau da yawa a cikin tsari kafin ƙaddamar da fim din oxide, saboda shirye-shiryen fim din oxide dole ne a gudanar da shi a kan wani cikakken tsabtaccen silicon wafer surface. Tsarin tsabtace wafer na silicon na yau da kullun shine kamar haka:

2.2 Busasshen Etching da Tsaftacewa

2.2.1 Busasshen Etching

Dry etching a cikin masana'antu galibi yana nufin etching plasma, wanda ke amfani da plasma tare da ingantaccen aiki don fitar da takamaiman abubuwa. Tsarin kayan aiki a cikin manyan matakan samarwa yana amfani da ƙananan zafin jiki mara daidaituwa.

Plasma etching galibi yana amfani da hanyoyin fitarwa guda biyu: fitarwa mai ƙarfi tare da fitarwa mai haɗakarwa

A cikin yanayin fitarwa mai ƙarfi tare da ƙarfi: Ana samar da plasma kuma ana kiyaye shi a cikin masu ƙarfin faranti guda biyu masu daidaitawa ta hanyar mitar rediyo ta waje (RF). Matsin iskar gas yawanci millitorr da yawa ne zuwa dubun millitorr, kuma adadin ionization bai wuce 10-5 ba. A cikin yanayin fitarwa mai haɗe-haɗe: gabaɗaya a ƙaramin iskar gas (dubun millitorr), ana samar da plasma kuma ana kiyaye shi ta hanyar shigar da kuzarin da aka haɗa tare. Matsakaicin ionization yawanci ya fi 10-5, don haka ana kiran shi plasma mai girma. Hakanan za'a iya samun maɓuɓɓugan plasma masu girma ta hanyar resonance na cyclotron na lantarki da fitar da igiyar ruwa ta cyclotron. Babban ƙwayar plasma na iya haɓaka ƙimar etching da zaɓin tsarin etching yayin rage lalacewar etching ta hanyar sarrafa kwararar ion da makamashin bama-bamai ta hanyar RF na waje ko wutar lantarki ta microwave da kuma samar da wutar lantarki na RF akan madaidaicin.

Tsarin bushewar etching shine kamar haka: ana shigar da iskar gas ɗin a cikin ɗakin ɗaukar motsi, kuma bayan an daidaita matsa lamba a cikin ɗakin amsawa, plasma yana haifar da fitarwa ta mitar rediyo; bayan da aka yi masa tasiri ta hanyar lantarki mai sauri, ya rushe don samar da radicals kyauta, wanda ke yaduwa zuwa saman ma'auni kuma ana tallata su. Karkashin aikin ion bombardment, radicals free adsorbed suna mayar da martani tare da atom ko kwayoyin halitta a saman ma'aunin don samar da iskar gas, wanda ake fitarwa daga ɗakin amsawa. Ana nuna tsarin a cikin adadi mai zuwa:

Ana iya raba matakan bushewa zuwa nau'i huɗu masu zuwa:

(1)Etching ta jiki: Ya fi dogara ga ions masu kuzari a cikin plasma don jefa bam a saman kayan da aka ƙulla. Adadin atom ɗin da aka watsa ya dogara da ƙarfi da kusurwar abubuwan da suka faru. Lokacin da makamashi da kusurwa ba su canza ba, yawan sputtering na kayan daban-daban yawanci ya bambanta da sau 2 zuwa 3 kawai, don haka babu zaɓi. Tsarin dauki shine yafi anisotropic.

(2)Chemical etching: Plasma yana samar da atoms da kwayoyin halitta, wanda ke amsa sinadarai tare da saman kayan don samar da iskar gas. Wannan halayen sinadarai zalla yana da zaɓi mai kyau kuma yana nuna halayen isotropic ba tare da la'akari da tsarin lattice ba.

Misali: Si (m) + 4F → SiF4 (gaseous), photoresist + O (gaseous) → CO2 (gaseous) + H2O (gaseous)

(3)ion makamashi kori etching: Ions duka biyun barbashi ne da ke haifar da etching da abubuwan da ke ɗaukar kuzari. Ingancin etching irin wannan barbashi masu ɗaukar kuzari ya fi tsari fiye da ɗaya girma fiye da na sassauƙan etching na zahiri ko sinadarai. Daga cikin su, haɓakar ma'auni na zahiri da sinadarai na tsari shine ainihin sarrafa tsarin etching.

(4)Ion-shamaki hada etching: Yafi nufin samar da wani polymer shãmaki kariya Layer ta hadaddun barbashi a lokacin etching tsari. Plasma yana buƙatar irin wannan Layer na kariya don hana etching martani na bangon gefe yayin aikin etching. Alal misali, ƙara C zuwa Cl da Cl2 etching na iya samar da ma'auni na chlorocarbon yayin etching don kare bangon gefe daga zama.

2.2.1 Tsabtace bushewa

Tsabtace bushewa galibi yana nufin tsaftacewar plasma. Ana amfani da ions a cikin plasma don yin bam a saman don tsaftacewa, kuma atom da kwayoyin da ke cikin jihar da aka kunna suna hulɗa tare da saman don tsaftacewa, don cirewa da toka na photoresist. Ba kamar busassun etching ba, sigogin tsari na tsabtace bushewa yawanci ba su haɗa da zaɓi na shugabanci ba, don haka ƙirar tsari yana da sauƙi. A cikin manyan matakan samarwa, ana amfani da iskar gas na tushen fluorine, oxygen ko hydrogen a matsayin babban jikin plasma na amsawa. Bugu da ƙari, ƙara wani adadin ƙwayar plasma na argon zai iya haɓaka tasirin bombardment na ion, don haka inganta aikin tsaftacewa.

A cikin tsarin tsabtace bushewar plasma, yawanci ana amfani da hanyar plasma mai nisa. Wannan shi ne saboda a cikin aikin tsaftacewa, ana fatan rage tasirin bombardment na ions a cikin plasma don sarrafa lalacewa ta hanyar fashewar ion; da haɓakar halayen sinadarai masu kyauta na iya inganta aikin tsaftacewa. Plasma mai nisa na iya amfani da microwaves don samar da plasma barga kuma mai girma a waje da ɗakin amsawa, yana samar da adadi mai yawa na radicals kyauta waɗanda ke shiga ɗakin amsawa don cimma nasarar da ake buƙata don tsaftacewa. Yawancin busassun tushen iskar gas a masana'antar suna amfani da iskar gas mai tushen fluorine, kamar NF3, kuma fiye da 99% na NF3 sun lalace a cikin plasma na microwave. Babu kusan babu tasirin fashewar ion a cikin tsarin tsabtace bushewa, don haka yana da amfani don kare wafer siliki daga lalacewa da kuma tsawaita rayuwar ɗakin amsawa.

Uku rigar etching da kayan tsaftacewa

3.1 Nau'in wafer na tanki mai tsabta

The trough-type wafer tsaftacewa inji shi ne yafi hada da gaban-bude wafer canja wuri akwatin watsa module, a wafer loading / sauke watsa watsa module, wani shaye iska ci module, wani sinadaran ruwa tank module, wani deionized ruwa tank module, wani bushewa tanki. module da tsarin sarrafawa. Yana iya tsaftace kwalaye da yawa na wafers a lokaci guda kuma zai iya cimma bushe-ciki da bushewa daga wafers.

3.2 Trench Wafer Etcher

3.3 Kayayyakin sarrafa rigar wafer guda ɗaya

Dangane da dalilai daban-daban na tsari, ana iya raba kayan aikin rigar wafer guda ɗaya zuwa nau'i uku. Nau'in farko shine kayan tsaftacewa guda ɗaya, waɗanda makasudin tsaftacewa sun haɗa da barbashi, kwayoyin halitta, Layer oxide na halitta, ƙazantattun ƙarfe da sauran gurɓatattun abubuwa; Nau'i na biyu kuma shi ne na'urorin goge-goge guda ɗaya, wanda babban manufar aiwatar da su shi ne cire ɓangarorin da ke saman wafer; Nau'i na uku shi ne na'urorin etching guda ɗaya, waɗanda galibi ana amfani da su don cire ƙananan fina-finai. Dangane da dalilai daban-daban na tsari, ana iya raba kayan etching guda ɗaya zuwa nau'i biyu. Nau'in farko shine kayan aikin etching mai laushi, wanda galibi ana amfani da shi don cire yadudduka lalata fim ɗin da ke haifar da haɓakar ion mai ƙarfi; Nau'i na biyu shine kayan aikin cire kayan hadaya, wanda galibi ana amfani da shi don cire shingen shinge bayan walƙiya na walƙiya ko goge kayan aikin sinadarai.

Daga hangen nesa na gine-ginen injin gabaɗaya, ainihin gine-ginen kowane nau'ikan kayan aikin rigar wafer guda ɗaya iri ɗaya ne, gabaɗaya ya ƙunshi sassa shida: babban firam, tsarin canja wurin wafer, tsarin ɗakin ɗakin, samar da ruwa mai sinadari da tsarin canja wuri, tsarin software. da kuma tsarin sarrafa lantarki.

3.4 Kayan Aikin Waya Mai Tsabtace

An tsara kayan aikin tsabtace wafer guda ɗaya bisa tsarin tsaftacewa na RCA na gargajiya, kuma manufar aiwatar da shi shine don tsabtace barbashi, kwayoyin halitta, Layer oxide na halitta, ƙazantattun ƙarfe da sauran gurɓataccen abu. Dangane da aikace-aikacen aiwatarwa, ana amfani da kayan aikin tsaftacewa guda ɗaya a halin yanzu a cikin gaba-gaba da ƙarshen aiwatarwa na masana'antar haɗaɗɗun kewaye, gami da tsaftacewa kafin da kuma bayan ƙirƙirar fim, tsaftacewa bayan etching plasma, tsaftacewa bayan ion implantation, tsaftacewa bayan sinadarai. injin goge-goge, da tsaftacewa bayan jigon ƙarfe. Ban da tsarin phosphoric acid mai zafin jiki, kayan aikin tsabtace wafer guda ɗaya yana dacewa da duk matakan tsaftacewa.

3.5 Kayan aikin Wafer guda ɗaya

Manufar aiwatar da kayan aikin wafer guda ɗaya shine yafi bakin ciki etching fim. Dangane da manufar tsari, ana iya raba shi zuwa nau'i biyu, wato, kayan aikin haske mai haske (wanda ake amfani da shi don cire fim ɗin lalacewa Layer wanda ke haifar da haɓakar ion mai ƙarfi) da kayan aikin cire kayan hadaya (wanda aka yi amfani da shi don cire shingen shinge bayan wafer. thinning ko sinadarai polishing). Abubuwan da ake buƙatar cirewa a cikin tsari gabaɗaya sun haɗa da silicon, silicon oxide, silicon nitride da yadudduka na fim na ƙarfe.

Hudu bushe etching da tsaftacewa kayan aiki

4.1 Rarraba kayan aikin etching na plasma

Baya ga ion sputtering etching kayan aiki wanda ke kusa da tsarkakakken dauki na jiki da kayan aikin lalatawa waɗanda ke kusa da halayen sinadarai masu tsabta, ana iya raba etching na plasma kusan kashi biyu bisa ga nau'ikan ƙirar plasma daban-daban da fasahar sarrafawa:

- Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwaƙwalwa (CCP);

-Etching Plasma Haɗe-haɗe (ICP).

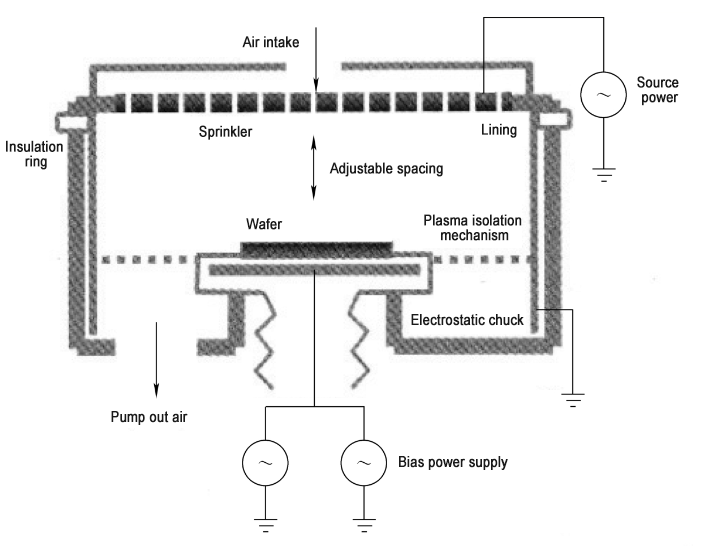

4.1.1 CCP

Haɗe-haɗe da ƙyalli na plasma etching mai ƙarfi shine haɗa wutar lantarki ta mitar rediyo zuwa ɗaya ko duka biyun na sama da na ƙananan lantarki a cikin ɗakin amsawa, kuma plasma tsakanin faranti guda biyu yana samar da capacitor a cikin sauƙaƙan da'ira.

Akwai irin waɗannan fasaha guda biyu na farko:

Ɗaya shine farkon etching na plasma, wanda ke haɗa wutar lantarki ta RF zuwa na'urar lantarki ta sama da ƙananan lantarki inda wafer yake ƙasa. Saboda plasma da aka samar ta wannan hanya ba zai samar da isasshen kullin ion mai kauri a saman wafer ba, ƙarfin ion bombardment ba ya da yawa, kuma yawanci ana amfani da shi a cikin matakai kamar etching silicon da ke amfani da ƙwayoyin aiki a matsayin babban abin da ake amfani da su.

Ɗayan shine farkon ion etching (RIE), wanda ke haɗa wutar lantarki ta RF zuwa ƙananan lantarki inda wafer yake, kuma yana sanya wutar lantarki ta sama tare da yanki mafi girma. Wannan fasaha na iya samar da kullin ion mai kauri, wanda ya dace da tsarin etching dielectric wanda ke buƙatar ƙarfin ion mafi girma don shiga cikin amsawa. Dangane da farkon ion etching mai amsawa, ana ƙara filin magnetic DC daidai da filin lantarki na RF don samar da drift na ExB, wanda zai iya haɓaka damar haɗarin electrons da barbashi na iskar gas, ta yadda ya inganta haɓaka ƙwayar plasma da ƙimar etching. Wannan etching ana kiransa Magnetic field enhanced reactive ion etching (MERIE).

Fasaha guda uku da ke sama suna da lahani na gama gari, wato, ba za a iya sarrafa ƙwayar plasma da ƙarfinsa daban ba. Misali, don haɓaka ƙimar etching, ana iya amfani da hanyar ƙara ƙarfin RF don haɓaka ƙwayar plasma, amma ƙara ƙarfin RF ba makawa zai haifar da haɓakar makamashin ion, wanda zai haifar da lalacewa ga na'urorin akan. wafer. A cikin shekaru goma da suka gabata, fasahar haɗin gwiwa mai ƙarfi ta karɓi ƙira na tushen RF da yawa, waɗanda aka haɗa da na sama da ƙananan na'urorin lantarki bi da bi ko duka zuwa ƙananan lantarki.

Ta zaɓi da daidaita nau'ikan RF daban-daban, yanki na lantarki, tazara, kayan aiki da sauran maɓalli masu mahimmanci suna daidaitawa tare da juna, za'a iya lalata ƙwayar plasma da makamashin ion gwargwadon yiwuwa.

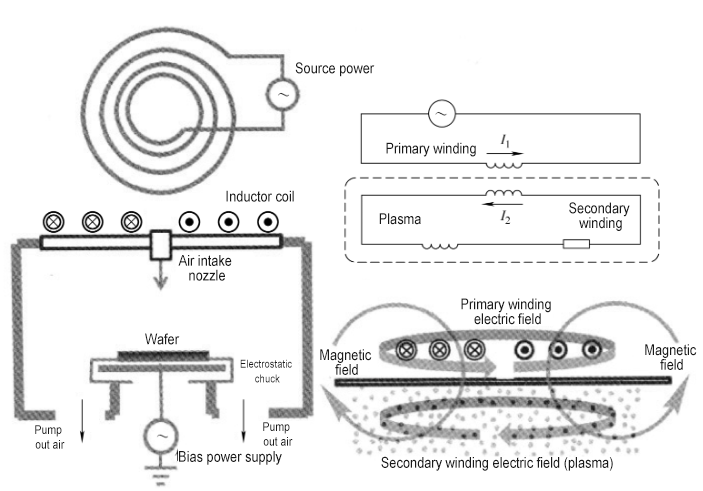

4.1.2 ICP

Haɗe-haɗe da ƙyalli na ƙwayar cuta ta plasma shine sanya saiti ɗaya ko fiye na coils da aka haɗa da wutar lantarki ta mitar rediyo akan ko kusa da ɗakin amsawa. Madadin filin maganadisu da mitar rediyo ke samarwa a cikin nada yana shiga ɗakin amsawa ta taga dielectric don haɓaka electrons, ta haka ne ke haifar da plasma. A cikin sauƙaƙan da'ira (mai canzawa), nada ita ce inductance ta farko, kuma plasma ita ce inductance ta biyu.

Wannan hanyar haɗin gwiwa na iya cimma ƙwayar plasma fiye da tsari ɗaya na girma fiye da haɗin kai a ƙananan matsi. Bugu da ƙari, ana haɗa wutar lantarki ta RF ta biyu zuwa wurin wafer a matsayin wutar lantarki mai ban sha'awa don samar da makamashin bombardment. Sabili da haka, ƙaddamarwar ion ya dogara ne akan tushen samar da wutar lantarki na coil kuma makamashin ion ya dogara ne akan samar da wutar lantarki na son rai, ta yadda za'a sami ƙarin ƙaddamar da hankali da makamashi.

4.2 Na'urar Etching Plasma

Kusan duk etchants da ke cikin busassun etching ana yin su ne kai tsaye ko a kaikaice daga plasma, don haka bushewar etching galibi ana kiransa etching plasma. Plasma etching wani nau'i ne na etching na jini a cikin ma'ana mai faɗi. A cikin ƙirar farantin faranti biyu na farko, ɗaya shine ƙasa farantin inda wafer yake, ɗayan kuma yana da alaƙa da tushen RF; ɗayan kuma akasin haka. A cikin tsohuwar ƙira, yanki na farantin ƙasa yawanci ya fi girma fiye da yankin farantin da aka haɗa da tushen RF, kuma matsa lamba gas a cikin reactor yana da girma. Kunshin ion da aka kafa a saman wafer ɗin yana da sirara sosai, kuma wafer ɗin yana da alama an “nutse” a cikin plasma. Etching galibi ana cika shi ta hanyar halayen sinadarai tsakanin ɓangarorin da ke aiki a cikin plasma da saman kayan da aka ƙulla. Ƙarfin ion bombardment yana da ƙananan ƙananan, kuma shigar da shi a cikin etching yana da ƙasa sosai. Wannan ƙirar ana kiranta yanayin etching plasma. A cikin wani zane, saboda matakin sa hannu na ion bombardment yana da girma sosai, ana kiran shi yanayin etching ion reactive.

4.3 Kayan Aikin Ion Mai Aiki

Reactive ion etching (RIE) yana nufin wani tsari na etching wanda barbashi masu aiki da ions da aka caje ke shiga cikin tsari a lokaci guda. Daga cikin su, barbashi masu aiki sune galibi masu tsaka-tsaki (wanda kuma aka sani da free radicals), tare da babban taro (kimanin 1% zuwa 10% na iskar gas), waɗanda sune manyan abubuwan da ake amfani da su. Kayayyakin da aka samar ta hanyar sinadarai tsakanin su da kayan da aka ƙera ana yin su ne ko dai sun lalace kuma an fitar da su kai tsaye daga ɗakin amsawa, ko kuma sun taru a saman datti; yayin da ions da aka caje suna cikin ƙananan ƙwayar cuta (10-4 zuwa 10-3 na iskar gas), kuma ana haɓaka su ta hanyar wutar lantarki na ion sheath da aka kafa a saman wafer don yin bombard saman. Akwai manyan ayyuka guda biyu na abubuwan da aka caje. Ɗayan shine ya lalata tsarin atomic na kayan da aka ƙera, ta haka yana haɓaka ƙimar abin da barbashi masu aiki suka yi da shi; ɗayan shine bam da kuma cire samfuran amsawar da aka tara ta yadda kayan da aka ƙera su kasance cikin cikakkiyar hulɗa tare da barbashi masu aiki, don ci gaba da etching.

Saboda ions ba sa shiga kai tsaye cikin amsawar etching (ko lissafin ɗan ƙaramin rabo, kamar cire bam na jiki da kuma fitar da sinadari kai tsaye na ions mai aiki), a tsanake, tsarin etching na sama yakamata a kira shi ion-assisted etching. Sunan reactive ion etching ba daidai ba ne, amma har yanzu ana amfani da shi a yau. An fara amfani da kayan aikin RIE na farko a cikin 1980s. Saboda amfani da wutar lantarki guda ɗaya ta RF da ƙirar ɗaki mai sauƙi, tana da iyakancewa dangane da ƙimar etching, daidaito da zaɓi.

4.4 Injin Magnetic Ingantattun Kayan aikin Ion Etching

Na'urar MERIE (Magnetically Enhanced Reactive Ion Etching) na'urar ce ta etching wacce aka gina ta ta ƙara filin maganadisu na DC zuwa na'urar RIE mai faffada kuma ana nufin ƙara ƙimar etching.

An yi amfani da kayan aikin MERIE akan babban sikeli a cikin 1990s, lokacin da kayan etching guda ɗaya ya zama kayan aiki na yau da kullun a cikin masana'antar. Babban rashin lahani na kayan aikin MERIE shine rashin daidaituwar rarraba sararin samaniya na maida hankali na plasma wanda filin maganadisu ya haifar zai haifar da bambance-bambancen halin yanzu ko ƙarfin lantarki a cikin na'urar da'ira mai haɗaka, wanda hakan zai haifar da lalacewar na'urar. Tunda wannan lalacewa ta samo asali ne ta rashin daidaituwa na gaggawa, jujjuyawar filin maganadisu ba zai iya kawar da shi ba. Yayin da girman da'irorin da'irori ke ci gaba da raguwa, lalacewar na'urarsu tana ƙara damuwa ga rashin daidaituwa na plasma, kuma fasahar haɓaka ƙimar etching ta haɓaka filin maganadisu sannu a hankali an maye gurbinsu da fasahar samar da wutar lantarki ta RF da yawa. shine, fasahar etching na jini mai ƙarfi.

4.5 Kayan aikin etching na plasma mai ƙarfi

Kayan aikin etching na plasma mai ƙarfi (CCP) na'ura ce da ke haifar da plasma a cikin ɗakin amsawa ta hanyar haɗakarwa mai ƙarfi ta hanyar amfani da mitar rediyo (ko DC) zuwa farantin lantarki kuma ana amfani dashi don etching. Ka'idar etching ta yayi kama da na kayan aikin ion mai amsawa.

Sauƙaƙen zane na kayan aikin etching na CCP an nuna a ƙasa. Gabaɗaya yana amfani da hanyoyin RF guda biyu ko uku na mitoci daban-daban, wasu kuma suna amfani da kayan wutar lantarki na DC. Mitar wutar lantarki ta RF shine 800kHz ~ 162MHz, kuma waɗanda aka saba amfani da su sune 2MHz, 4MHz, 13MHz, 27MHz, 40MHz da 60MHz. Samfuran wutar lantarki na RF tare da mitar 2MHz ko 4MHz galibi ana kiran su tushen RF ƙananan mitoci. Gabaɗaya ana haɗa su da ƙananan lantarki inda wafer yake. Sun fi tasiri wajen sarrafa makamashin ion, don haka ana kiransu da samar da wutar lantarki na son zuciya; Samfuran wutar lantarki na RF tare da mitar sama da 27MHz ana kiran su manyan hanyoyin RF masu tsayi. Ana iya haɗa su da ko dai na sama ko na ƙasa. Sun fi tasiri wajen sarrafa taro na plasma, don haka ana kiran su da samar da wutar lantarki. Samar da wutar lantarki na 13MHz RF yana tsakiyar kuma ana ɗauka gabaɗaya yana da duka ayyukan da ke sama amma sun fi rauni. Lura cewa ko da yake ana iya daidaita maida hankali na plasma da makamashi a cikin wani takamaiman kewayon ta ikon tushen RF na mitoci daban-daban (abin da ake kira tasirin decoupling), saboda halayen haɗin haɗin gwiwa, ba za a iya daidaita su da sarrafa su gaba ɗaya da kansu ba.

Rarraba makamashi na ion yana da tasiri mai mahimmanci akan cikakken aikin etching da lalacewar na'urar, don haka haɓaka fasahar don inganta rarraba makamashin ion ya zama ɗaya daga cikin mahimman abubuwan kayan aikin etching na gaba. A halin yanzu, fasahohin da aka samu nasarar amfani da su wajen samarwa sun haɗa da ɗimbin RF hybrid drive, DC superposition, RF hade da DC bugun jini son zuciya, da synchronous pulsed RF fitarwa na son zuciya samar da wutar lantarki da tushen samar da wutar lantarki.

Kayan aikin etching na CCP ɗaya ne daga cikin nau'ikan nau'ikan etching na plasma guda biyu da aka fi amfani dasu. An yafi amfani da shi a cikin tsarin etching na dielectric kayan, kamar ƙofar sidewall da wuya mask etching a gaban mataki na dabaru guntu aiwatar, lamba rami etching a tsakiyar mataki, mosaic da aluminum kushin etching a baya mataki, kazalika da. etching na zurfin ramuka, ramuka masu zurfi da ramukan tuntuɓar wayoyi a cikin 3D flash memory guntu tsarin (ɗaukar silinda nitride/tsarin siliki a matsayin misali).

Akwai manyan ƙalubalen guda biyu da jagororin haɓakawa da kayan aikin CCP ke fuskanta. Na farko, a cikin aikace-aikace na musamman high ion makamashi, da etching iyawar babban al'amari rabo Tsarin (kamar rami da tsagi etching na 3D flash memory na bukatar wani rabo sama da 50:1). Hanyar da ake amfani da ita na ƙara ƙarfin son zuciya don ƙara ƙarfin ion ya yi amfani da wutar lantarki na RF har zuwa 10,000 watts. Dangane da babban adadin zafi da aka samar, ana buƙatar ci gaba da haɓaka fasahar sanyaya da zafin jiki na ɗakin amsawa. Na biyu, akwai bukatar samun ci gaba wajen samar da sabbin iskar gas don warware matsalar iyawa.

4.6 Kayan aikin Etching Plasma Haɗe-haɗe

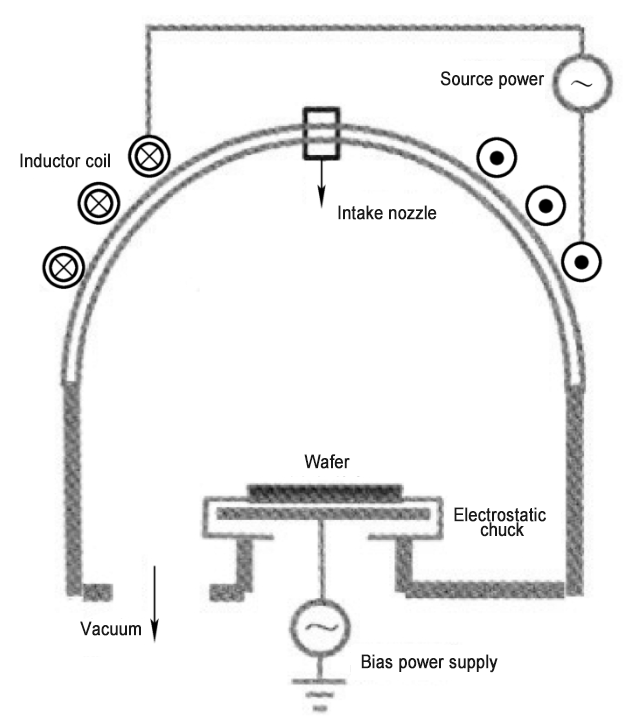

Na'urar etching mai haɗaɗɗiyar plasma (ICP) na'ura ce da ke haɗa ƙarfin wutar lantarki ta mitar rediyo zuwa ɗakin amsawa a cikin nau'in filin maganadisu ta hanyar na'urar inductor, ta haka ne ke samar da plasma don etching. Ka'idar etching ɗinta kuma tana cikin ion etching ɗin gabaɗaya.

Akwai manyan nau'ikan ƙira na tushen plasma guda biyu don kayan etching na ICP. Daya ita ce fasahar taransfoma hade da plasma (TCP) wanda Lam Research ya kirkira kuma ya samar. Ana sanya coil ɗin inductor ɗinsa akan jirgin saman taga dielectric sama da ɗakin amsawa. Sigina na 13.56MHz RF yana haifar da canjin yanayin maganadisu a cikin coil wanda yake daidai da taga dielectric kuma yana rarrabuwa tare da axis na coil azaman tsakiya.

Filin maganadisu yana shiga ɗakin amsawa ta taga dielectric, kuma madaidaicin filin maganadisu yana haifar da madaidaicin filin lantarki daidai da taga dielectric a cikin ɗakin amsawa, don haka ya sami rabuwar iskar gas da samar da plasma. Tun da ana iya fahimtar wannan ka'ida azaman mai canzawa tare da inductor coil azaman iska ta farko da plasma a cikin ɗakin amsawa azaman iska ta biyu, ana kiran ICP etching bayan wannan.

Babban fa'idar fasahar TCP shine cewa tsarin yana da sauƙin haɓakawa. Misali, daga wafer 200mm zuwa wafer 300mm, TCP na iya kiyaye tasirin etching iri ɗaya ta hanyar ƙara girman nada kawai.

Wata ƙira ta tushen plasma ita ce fasahar da aka lalatar da tushen plasma (DPS) wanda Applied Materials, Inc. na Amurka ya haɓaka kuma ya samar. Nadin inductor nata yana da rauni mai fuska uku akan tagar dielectric na hemispherical. Ka'idar samar da plasma tana kama da fasahar TCP da aka ambata, amma ingancin rarrabawar iskar gas yana da girma, wanda ke da amfani don samun mafi girman ƙwayar plasma.

Tunda ingancin haɗaɗɗen haɗakarwa don samar da plasma ya fi na capacitive coupling, kuma ana samar da plasma galibi a cikin yanki kusa da taga dielectric, ana ƙaddara ƙimar plasma ta asali ta ikon tushen samar da wutar lantarki da aka haɗa da inductor. nada, da kuma makamashin ion a cikin sheath ion akan saman wafer an ƙaddara shi ne ta hanyar ƙarfin wutar lantarki na bias, don haka maida hankali da kuzarin ions na iya zama da kansa. sarrafawa, ta yadda za a cimma decoupling.

Kayan aikin etching na ICP ɗaya ne daga cikin nau'ikan kayan etching na plasma guda biyu da aka fi amfani da su. Ana amfani dashi galibi don etching na ramuka mara zurfi na siliki, germanium (Ge), tsarin ƙofar polysilicon, tsarin ƙofar ƙarfe, siliki mai ɗorewa (Strained-Si), wayoyi na ƙarfe, pads ɗin ƙarfe (Pads), mosaic etching ƙarfe mai wuyar masks da matakai da yawa a ciki. fasahar hoto da yawa.

Bugu da kari, tare da Yunƙurin na uku-girma hadedde da'irori, CMOS image na'urori masu auna firikwensin da micro-electro-mechanical tsarin (MEMS), kazalika da saurin karuwa a aikace-aikace ta hanyar silicon vias (TSV), manyan-size oblique ramukan da kuma zurfin siliki etching tare da nau'ikan nau'ikan halittu daban-daban, masana'antun da yawa sun ƙaddamar da kayan aikin etching waɗanda aka haɓaka musamman don waɗannan aikace-aikacen. Halayensa babban zurfin etching ne (dubun ko ma ɗaruruwan microns), don haka galibi yana aiki a ƙarƙashin babban kwararar iskar gas, matsanancin matsin lamba da yanayi mai ƙarfi.

——————————————————————————————————————————————————— ———————————-

Semicera na iya bayarwasassa graphite, taushi / m ji, silicon carbide sassa, CVD silicon carbide sassa, kumaSiC/TaC rufaffiyar sassatare da cikin kwanaki 30.

Idan kuna sha'awar samfuran semiconductor na sama,don Allah kar a yi shakka a tuntube mu a farkon lokaci.

Lambar waya: +86-13373889683

WhatsApp: +86-15957878134

Email: sales01@semi-cera.com

Lokacin aikawa: Agusta-31-2024