1. Gabatarwa

Hanyar haɗa abubuwa (raw kayan) zuwa saman kayan ƙasa ta hanyar jiki ko sinadarai ana kiransa ci gaban fim na bakin ciki.

Dangane da ka'idodin aiki daban-daban, haɗaɗɗen jigilar fim ɗin bakin ciki za a iya raba zuwa:

-Turin Turin Jiki (PVD);

-Tsarin Turin Sinadarai (CVD);

- Tsawaitawa.

2. Tsarin Ci gaban Fina-Finan Siriri

2.1 Zubar da tururi ta jiki da aiwatar da sputtering

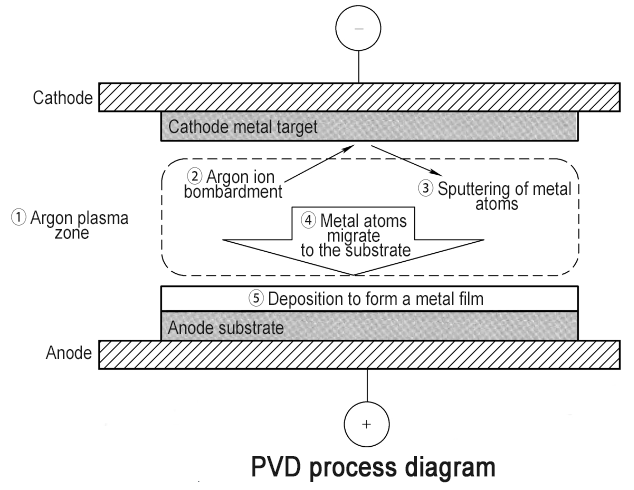

Tsarin tururi na jiki (PVD) yana nufin yin amfani da hanyoyin jiki kamar zubar da ruwa, sputtering, suturar plasma da ƙwayar ƙwayar ƙwayar cuta don samar da fim na bakin ciki a saman wafer.

A cikin masana'antar VLSI, fasahar PVD da aka fi amfani da ita ita ce sputtering, wanda galibi ana amfani da ita don igiyoyi da haɗin haɗin ƙarfe na haɗaɗɗun da'irori. Sputtering wani tsari ne wanda ake sanya iskar gas da ba kasafai ba [kamar argon (Ar)] su zama ion (kamar Ar +) a karkashin aikin filin lantarki na waje a karkashin yanayi mara kyau, kuma suna jefar da tushen abin da aka yi niyya a karkashin yanayin wutar lantarki mai girma, buga fitar da kwayoyin halitta ko kwayoyin halitta na abin da aka yi niyya, sannan su isa saman wafer don samar da fim na bakin ciki bayan tsarin jirgin da ba shi da karo. Ar yana da kaddarorin sinadarai masu tsayayye, kuma ions ɗinsa ba za su yi amsa da sinadarai ba tare da abin da aka yi niyya da fim ɗin. Kamar yadda hadedde kwakwalwan kwamfuta shiga cikin 0.13μm jan karfe interconnected zamanin, jan karfe abu Layer yana amfani da titanium nitride (TiN) ko tantalum nitride (TaN) fim. Bukatar fasahar masana'antu ta inganta bincike da haɓaka fasahar harabar sinadarai, wato a cikin ɗakin sputtering, ban da Ar, akwai kuma iskar iskar gas mai amsawa (N2), ta yadda Ti ko Ta bam daga Abubuwan da aka yi niyya Ti ko Ta suna amsawa tare da N2 don samar da fim ɗin TiN ko TaN da ake buƙata.

Akwai hanyoyin sputtering guda uku da aka saba amfani da su, wato DC sputtering, RF sputtering da magnetron sputtering. Yayin da haɗin gwiwar haɗin gwiwar haɗin gwiwar ke ci gaba da karuwa, adadin nau'o'in nau'i na nau'i-nau'i na nau'i-nau'i yana karuwa, kuma aikace-aikacen fasaha na PVD yana karuwa sosai. Kayan PVD sun haɗa da Al-Si, Al-Cu, Al-Si-Cu, Ti, Ta, Co, TiN, TaN, Ni, WSi2, da dai sauransu.

PVD da sputtering matakai yawanci kammala a cikin wani sosai shãfe haske dauki dakin tare da injin digiri na 1 × 10-7 zuwa 9 × 10-9 Torr, wanda zai iya tabbatar da tsarki na gas a lokacin dauki; a lokaci guda, ana buƙatar babban ƙarfin lantarki na waje don ionize da ƙarancin iskar gas don samar da isasshen ƙarfin lantarki don jefar da abin da ake hari. Babban sigogi don kimanta PVD da matakan sputtering sun haɗa da adadin ƙura, da ƙimar juriya, daidaituwa, kauri mai nuna alama da damuwa na fim ɗin da aka kafa.

2.2 Tsarin Turin Sinadari da Tsari

Chemical tururi ajiya (CVD) yana nufin wani tsari fasaha a cikin abin da iri-iri gaseous reactants tare da daban-daban partial matsi amsa chemically a wani zafin jiki da kuma matsa lamba, da kuma generated m abubuwa suna ajiya a saman da substrate abu don samun da ake so bakin ciki. fim. A cikin tsarin masana'antar da'ira na gargajiya na gargajiya, kayan fim na bakin ciki da aka samu gabaɗaya mahadi ne kamar oxides, nitrides, carbides, ko kayan kamar silicon polycrystalline da silicon amorphous. Zaɓin girma epitaxial, wanda aka fi amfani da shi bayan kumburin 45nm, kamar tushe da magudanar ruwa SiGe ko Si zaɓin ci gaban epitaxial, shima fasahar CVD ce.

Wannan fasaha na iya ci gaba da samar da kayan kristal guda ɗaya na nau'in iri ɗaya ko kama da na asali na asali akan nau'in kristal guda ɗaya na silicon ko wasu kayan tare da lattice na asali. Ana amfani da CVD sosai a cikin haɓakar fina-finan dielectric insulating (kamar SiO2, Si3N4 da SiON, da sauransu) da fina-finai na ƙarfe (kamar tungsten, da sauransu).

Gabaɗaya, bisa ga rarrabuwar matsa lamba, CVD za a iya raba zuwa na yanayi matsa lamba sinadaran tururi tarawa (APCVD), sub-yanayin matsa lamba sinadaran tururi ajiya (SAPCVD) da kuma low matsa lamba sinadaran tururi (LPCVD).

Dangane da rabe-raben zafin jiki, CVD za a iya raba zuwa babban zafin jiki / ƙananan zafin jiki na oxide fim ɗin sinadarai (HTO / LTO CVD) da kuma saurin iskar gas mai zafi (Rapid Thermal CVD, RTCVD);

Dangane da tushen amsawa, ana iya raba CVD zuwa CVD na tushen silane, CVD na tushen polyester (CVD na tushen TEOS) da jigilar ƙwayoyin sinadarai na ƙarfe (MOCVD);

Dangane da rabe-raben makamashi, ana iya raba CVD zuwa jigon tururin sinadarai na thermal (Thermal CVD), ingantacciyar tururin sinadarai na plasma (CVD Enhanced Plasma, PECVD). Kwanan nan, isassun tururin sinadarai mai gudana (CVD mai gudana, FCVD) tare da ingantacciyar ikon cike gibin shima an haɓaka.

Daban-daban na CVD-girma fina-finai da daban-daban kaddarorin (kamar sinadaran abun da ke ciki, dielectric akai-akai, tashin hankali, danniya da rushewar ƙarfin lantarki) kuma za a iya amfani da daban-daban bisa ga daban-daban tsari bukatun (kamar zazzabi, mataki ɗaukar hoto, cika bukatun, da dai sauransu).

2.3 Atomic Layer tsarin sakawa

Atomic Layer Deposition (ALD) yana nufin ƙaddamar da atom ɗin Layer ta Layer akan wani abu mai tushe ta hanyar girma Layer fim ɗin atomic guda ɗaya ta Layer. ALD na yau da kullun yana ɗaukar hanyar shigar da iskar gas a cikin na'ura ta hanyar juzu'i.

Misali, da farko, an gabatar da precursor na amsawa 1 a cikin farfajiyar ƙasa, kuma bayan tallan sinadarai, an samar da Layer atomic guda ɗaya akan saman ƙasa; sa'an nan precursor 1 saura a kan substrate surface da kuma a cikin dauki dakin da ake pumped daga wani iska famfo; sa'an nan kuma an gabatar da precursor 2 a cikin substrate surface, kuma chemically reacts tare da precursor 1 adsorbed a kan substrate surface don samar da daidai bakin ciki film abu da kuma m by-samfurori a kan substrate surface; lokacin da precursor 1 ya amsa gaba daya, amsawar za ta ƙare ta atomatik, wanda shine yanayin iyakancewar kai na ALD, sa'an nan kuma ana fitar da sauran reactants da samfuran samfuran don shirya don mataki na gaba na girma; ta hanyar maimaita abin da ke sama a ci gaba, za a iya cimma jigon kayan fim na bakin ciki da aka girma Layer by Layer tare da atom guda ɗaya.

Dukansu ALD da CVD hanyoyi ne na gabatar da tushen amsa sinadarai na gaseous don amsa sinadarai a saman saman ƙasa, amma bambancin shine tushen amsawar gaseous na CVD ba shi da sifa ta iyakance girman kai. Ana iya ganin cewa mabuɗin haɓaka fasahar ALD shine nemo magabatan da ke da kaddarorin amsawa mai iyakancewa.

2.4 Tsarin Epitaxial

Tsarin Epitaxial yana nufin aiwatar da girma gaba ɗaya da aka ba da umarni Layer Layer crystal a kan ma'auni. Gabaɗaya magana, tsarin epitaxial shine haɓaka Layer Layer tare da daidaitawar lattice iri ɗaya kamar asalin asali akan madaidaicin kristal guda ɗaya. Ana amfani da tsarin Epitaxial sosai a masana'antar semiconductor, irin su siliki na siliki na epitaxial a cikin masana'antar da'ira mai hadewa, tushen da aka saka da magudanar ruwa na epitaxial na MOS transistor, girma epitaxial akan substrates LED, da sauransu.

Dangane da yanayi daban-daban na tushen girma, hanyoyin haɓaka epitaxial za a iya raba su zuwa ƙaƙƙarfan lokaci epitaxy, ruwa lokaci epitaxy, da vapor period epitaxy. A cikin masana'antar da'ira mai haɗaka, hanyoyin da ake amfani da su na epitaxial sune ƙaƙƙarfan lokaci epitaxy da tururi lokaci epitaxy.

Tsayayyen lokaci epitaxy: yana nufin haɓakar Layer Layer guda ɗaya akan ma'auni ta amfani da ingantaccen tushe. Misali, kawar da zafin jiki bayan dasa ion shine ainihin tsari mai ƙarfi na epitaxy. A lokacin dasa ion, ion silicon atom na wafer siliki suna bombarded da ions masu ƙarfi masu ƙarfi, suna barin matsayinsu na lattice na asali kuma sun zama amorphous, suna samar da saman siliki mai amorphous. Bayan zafi mai zafi mai zafi, amorphous atoms suna komawa zuwa matsayinsu na lattice kuma su kasance daidai da daidaitawar atomic crystal a cikin substrate.

Hanyoyin ci gaban tururi lokaci epitaxy sun hada da sinadaran tururi lokaci epitaxy, kwayoyin katako epitaxy, atomic Layer epitaxy, da dai sauransu. A cikin hadedde kewaye masana'antu, sinadaran tururi lokaci epitaxy ne da aka fi amfani. Ka'idar sinadari mai tururi lokaci epitaxy asali iri ɗaya ne da na jimillar tururin sinadarai. Dukansu matakai ne da ke adana fina-finai na bakin ciki ta hanyar yin amsa da sinadarai a saman wafers bayan haɗewar iskar gas.

Bambance-bambancen shine saboda sinadarin tururi lokaci epitaxy yana girma Layer crystal guda ɗaya, yana da mafi girman buƙatu don abubuwan da ke cikin ƙazanta a cikin kayan aiki da tsabtar farfajiyar wafer. Ana buƙatar aiwatar da tsarin tururi na farko na siliki na epitaxial a ƙarƙashin yanayin zafi mai girma (fiye da 1000 ° C). Tare da haɓaka kayan aiki na tsari, musamman ɗaukar fasahar ɗakin musanya na injin, an inganta tsabtar rami na kayan aiki da saman wafer siliki, kuma ana iya aiwatar da epitaxy silicon a ƙaramin zafin jiki (600-700 °). C). Tsarin wafer na siliki na epitaxial shine haɓaka Layer na silicon crystal siliki ɗaya akan saman wafer siliki.

Idan aka kwatanta da asalin siliki na asali, Layer silicon epitaxial yana da tsabta mafi girma da ƙarancin lahani, don haka haɓaka yawan masana'anta na semiconductor. Bugu da ƙari, haɓakar girma da haɓakar doping na epitaxial silicon Layer da aka girma akan wafer siliki za a iya tsara shi da sauƙi, wanda ke kawo sassauci ga ƙirar na'urar, kamar rage juriya na substrate da haɓaka keɓancewar ƙasa. Tsarin epitaxial na tushen-magudanar ruwa fasaha ce da aka yi amfani da ita sosai a cikin nodes ɗin fasahar dabaru na ci gaba.

Yana nufin tsarin girma na germanium silicon ko silicon a cikin tushen da magudanar ruwa na MOS transistor. Babban abũbuwan amfãni na gabatar da tushen tushen-drain epitaxial tsari sun hada da: girma wani pseudocrystalline Layer dauke da danniya saboda lattice adaptation, inganta tashar m motsi; Doping a cikin wuri na tushen da magudanar ruwa na iya rage juriya na parasitic na mahaɗar magudanar ruwa da rage lahani na haɓakar ion mai ƙarfi.

3. bakin ciki fim girma kayan aiki

3.1 Vacuum evaporation kayan aiki

Vacuum evaporation wata hanya ce ta shafa wanda ke dumama daskararrun kayan a cikin daki don sa su yi ƙafe, tururi ko ƙasa, sannan kuma su tattara su ajiye a saman wani abu mai zafi a wani yanayin zafi.

Yawanci ya ƙunshi sassa uku, wato tsarin vacuum, tsarin evaporation da tsarin dumama. Tsarin injin ɗin ya ƙunshi bututun mai da injin famfo, kuma babban aikinsa shine samar da ingantaccen yanayi don ƙafewa. Tsarin evaporation ya ƙunshi tebur na evaporation, kayan dumama da kuma ma'aunin zafin jiki.

Abubuwan da aka yi niyya don fitar da su (kamar Ag, Al, da dai sauransu) an sanya su a kan teburin ƙafe; bangaren dumama da ma'aunin zafin jiki shine tsarin rufaffiyar madauki da ake amfani da shi don sarrafa yawan zafin jiki don tabbatar da fitar da ruwa mai santsi. Tsarin dumama ya ƙunshi matakin wafer da kayan dumama. Ana amfani da matakin wafer don sanya madaidaicin abin da fim ɗin bakin ciki ya buƙaci a fitar da shi, kuma ana amfani da ɓangaren dumama don gane dumama dumama da sarrafa ma'aunin zafin jiki.

Yanayin vacuum wani yanayi ne mai mahimmanci a cikin tsarin zubar da ruwa, wanda ke da alaka da yawan iska da ingancin fim din. Idan vacuum digiri bai cika buƙatun ba, ƙwayoyin zarra ko ƙwayoyin cuta za su yi karo akai-akai tare da ragowar ƙwayoyin iskar gas, suna mai da ma'anarsu ta 'yanci ƙarami, kuma atom ko kwayoyin za su watse sosai, ta haka ne za su canza alkiblar motsi da rage fim ɗin. yawan samuwar.

Bugu da ƙari, saboda kasancewar ragowar ƙwayoyin iskar gas na ƙazanta, fim ɗin da aka ajiye yana da mummunar gurɓatacce kuma ba shi da kyau, musamman ma lokacin da yawan hawan ɗakin ɗakin bai dace da ma'auni ba kuma akwai zubar da iska, iska za ta shiga cikin ɗakin ɗakin. , wanda zai yi tasiri sosai ga ingancin fim.

Halayen tsarin kayan aikin injin ƙafewa sun ƙayyade cewa daidaituwar suturar a kan manyan abubuwan da ke ƙasa ba ta da kyau. Domin inganta daidaiton sa, ana amfani da hanyar da za a ƙara nisa mai tushe-substrate da jujjuya substrate gabaɗaya, amma haɓaka tazarar tushen tushen zai sadaukar da ƙimar girma da tsabtar fim ɗin. A lokaci guda, saboda karuwa a cikin sararin samaniya, yawan amfani da kayan da aka kwashe yana raguwa.

3.2 DC tururi jijiya kayan aiki

Tushen tururi na yanzu kai tsaye (DCPVD) kuma ana saninsa da sputtering cathode ko vacuum DC sputtering mataki biyu. Ana amfani da kayan da aka yi niyya na vacuum DC sputtering azaman cathode kuma ana amfani da substrate azaman anode. Vacuum sputtering shine samar da plasma ta hanyar ionizing iskar gas.

Abubuwan da aka caje a cikin plasma suna haɓaka a cikin filin lantarki don samun takamaiman adadin kuzari. Barbashin da ke da isassun kuzari suna jefa bama-bamai a saman abin da aka yi niyya, ta yadda za a iya watsar da zarra; atom ɗin da aka watsar tare da wani takamaiman kuzarin motsa jiki suna motsawa zuwa ƙasa don samar da fim na bakin ciki a saman ƙasan. Gas da ake amfani da shi don watsawa gabaɗaya iskar gas ce da ba kasafai ba, kamar argon (Ar), don haka fim ɗin da aka yi ta fantsama ba zai gurɓata ba; Bugu da kari, atomic radius na argon ya fi dacewa da sputtering.

Girman ɓangarorin sputtering dole ne ya kasance kusa da girman maƙasudin atom ɗin da za a sputtered. Idan barbashi sun yi girma ko ƙanƙanta, ba za a iya samar da ingantaccen sputtering ba. Baya ga girman ma'aunin zarra, ma'aunin atom ɗin zai kuma shafi ingancin sputtering. Idan tushen barbashi na sputtering ya yi haske da yawa, ba za a tofa atom ɗin da aka yi niyya ba; idan ɓangarorin sputtering sun yi nauyi sosai, za a “lankwashe” abin da aka sa a gaba kuma ba za a tofa ba.

Abubuwan da ake nufi da amfani da su a cikin DCPVD dole ne su zama jagora. Wannan shi ne saboda lokacin da argon ions a cikin tsari gas ya jefar da abin da ake nufi, za su sake haɗuwa da electrons a saman abin da ake nufi. Lokacin da abin da ake nufi da shi shine madugu kamar karfe, electrons da wannan haɗin ke cinyewa ana samun sauƙin cika su ta hanyar samar da wutar lantarki da kuma electrons kyauta a wasu sassa na abin da ake nufi ta hanyar lantarki, ta yadda fuskar kayan da aka yi niyya a matsayin gabaɗayan ragowar caja mara kyau kuma ana kiyaye sputtering.

Sabanin haka, idan abin da aka yi niyya shi ne insulator, bayan da electrons da ke saman abin da aka yi niyya sun sake haɗuwa da su, ba za a iya cika su ta hanyar lantarki ba tare da kyauta na electrons a wasu sassa na abin da ake nufi ba, har ma da caji mai kyau zai taru akan saman abin da aka yi niyya, yana haifar da yuwuwar abin da ake niyya ya tashi, kuma mummunan cajin abin da ake nufi yana raunana har sai ya ɓace, a ƙarshe yana haifar da ƙarshen sputtering.

Sabili da haka, don yin kayan da za a iya amfani da su don yin sputtering, dole ne a sami wata hanyar sputtering. Fitar mitar rediyo hanya ce mai totsawa wacce ta dace da maƙasudin gudanarwa da waɗanda ba su kai ba.

Wani rashin lahani na DCPVD shine ƙarfin wutan wuta yana da girma kuma bama-bamai na lantarki akan ƙasa yana da ƙarfi. Hanya mai mahimmanci don magance wannan matsala ita ce amfani da magnetron sputtering, don haka magnetron sputtering yana da ƙima mai amfani a fagen haɗakarwa.

3.3 RF Kayan Aikin Jiki na Turin Jiki

Mitar rediyo ta jiki (RFPVD) tana amfani da ƙarfin mitar rediyo azaman tushen zumuɗi kuma hanya ce ta PVD wacce ta dace da nau'ikan ƙarfe da kayan da ba na ƙarfe ba.

Mitoci gama gari na wutar lantarki na RF da ake amfani da su a cikin RFPVD sune 13.56MHz, 20MHz, da 60MHz. Zagaye masu inganci da mara kyau na wutar lantarki na RF suna bayyana a madadin. Lokacin da maƙasudin PVD ya kasance a cikin ingantaccen zagayowar rabin zagayowar, saboda yanayin da ake niyya yana da kyakkyawar ma'ana, electrons a cikin yanayin tsari za su gudana zuwa farfajiyar manufa don kawar da ingantaccen cajin da aka tara a saman sa, har ma ya ci gaba da tara electrons. yin fuskarsa mara kyau; lokacin da maƙasudin sputtering ya kasance a cikin raƙuman rabin sake zagayowar, ingantattun ions za su matsa zuwa ga abin da ake nufi kuma za su kasance masu ɓarna a wani yanki a kan abin da ake nufi.

Abu mafi mahimmanci shi ne cewa saurin motsi na electrons a cikin filin lantarki na RF yana da sauri fiye da na ions masu kyau, yayin da lokacin raƙuman raƙuman raƙuman raƙuman raƙuman ruwa da kuma maras kyau sun kasance iri ɗaya, don haka bayan cikakken zagayowar, farfajiyar manufa za ta kasance. "net" mara kyau. Sabili da haka, a cikin ƙananan hawan keke na farko, mummunan cajin da aka yi niyya yana nuna haɓakar haɓaka; bayan haka, maƙasudin da aka yi niyya ya kai ga barga mara kyau; bayan haka, saboda mummunan cajin da aka yi niyya yana da tasiri mai banƙyama a kan electrons, adadin cajin tabbatacce da mara kyau da aka karɓa ta hanyar lantarki da aka yi niyya yana kula da daidaitawa, kuma maƙasudin yana gabatar da caji mara kyau.

Daga tsarin da ke sama, ana iya ganin cewa tsarin samar da wutar lantarki mara kyau ba shi da alaƙa da kaddarorin abin da aka yi niyya da kansa, don haka hanyar RFPVD ba kawai za ta iya magance matsalar sputtering na insulating hari ba, amma kuma yana da jituwa sosai. tare da na al'ada karfe madugu hari.

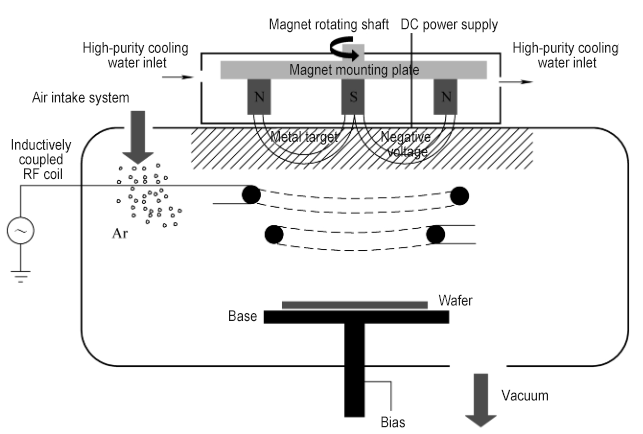

3.4 Magnetron sputtering kayan aiki

Magnetron sputtering hanya ce ta PVD wacce ke ƙara maganadisu zuwa baya na manufa. Abubuwan da aka ƙara maganadisu da tsarin samar da wutar lantarki na DC (ko wutar lantarki ta AC) suna samar da tushen sputtering magnetron. Ana amfani da tushen sputtering don samar da filin lantarki mai hulɗa a cikin ɗakin, kamawa da iyakance yawan motsi na electrons a cikin plasma a cikin ɗakin, fadada hanyar motsi na electrons, don haka yana ƙara yawan haɗuwa da plasma, kuma a ƙarshe samun nasara. ajiya.

Bugu da ƙari, saboda ƙarin electrons suna daure kusa da saman abin da aka yi niyya, bama-bamai na substrate ta hanyar electrons yana raguwa, kuma zafin jiki yana raguwa. Idan aka kwatanta da fasahar DCPVD mai lebur, ɗaya daga cikin fitattun fasalulluka na fasahar tara tururin jiki na magnetron shine cewa ƙarfin fitarwa na ƙonewa yana da ƙasa kuma ya fi karko.

Saboda mafi girman maida hankalin sa na plasma da mafi girman yawan amfanin gona, zai iya cimma ingantacciyar ingantacciyar ajiya, sarrafa kauri a cikin babban kewayon, madaidaicin sarrafa abun da ke ciki da ƙananan ƙarfin wuta. Saboda haka, magnetron sputtering ne a cikin wani rinjaye matsayi a halin yanzu karfe film PVD. Mafi sauƙaƙan ƙirar tushen sputtering magnetron shine sanya ƙungiyar maganadiso a bayan madaidaicin manufa (a wajen tsarin vacuum) don samar da filin maganadisu daidai da farfajiyar manufa a cikin yanki na gida akan farfajiyar manufa.

Idan aka sanya maganadisu na dindindin, filin maganadisu yana da ƙayyadaddun ƙayyadaddun ƙayyadaddun yanayin, wanda ke haifar da ƙayyadaddun filayen maganadisu a kan abin da ake nufi a cikin ɗakin. Abubuwan kawai a cikin takamaiman wuraren da aka yi niyya ana zubar da su, ƙimar amfani da manufa ba ta da yawa, kuma daidaiton fim ɗin da aka shirya ba shi da kyau.

Akwai yuwuwar cewa karfen da aka zube ko wasu ɓangarorin kayan za'a dawo dasu akan farfajiyar da aka nufa, ta haka za'a tattara su cikin ɓangarorin kuma suna haifar da gurɓataccen lahani. Saboda haka, kasuwancin magnetron sputtering kafofin galibi suna amfani da ƙirar maganadisu mai jujjuya don haɓaka daidaiton fim, ƙimar amfani da manufa, da cikakkiyar maƙasudin sputtering.

Yana da mahimmanci a daidaita waɗannan abubuwa guda uku. Idan ba a kula da ma'auni da kyau ba, yana iya haifar da ingantaccen daidaiton fim yayin da yake rage yawan amfani da manufa (gajarta rayuwar manufa), ko kasa cimma cikakkiyar sputtering manufa ko lalata manufa, wanda zai haifar da matsalolin barbashi yayin sputtering. tsari.

A cikin fasahar PVD na magnetron, ya zama dole a yi la'akari da injin motsi na maganadisu, siffar manufa, tsarin sanyaya manufa da tushen sputtering magnetron, kazalika da tsarin aiki na tushe wanda ke ɗaukar wafer, kamar tallan wafer da sarrafa zafin jiki. A cikin tsarin PVD, ana sarrafa yawan zafin jiki na wafer don samun tsarin crystal da ake buƙata, girman hatsi da daidaitawa, da kuma kwanciyar hankali na aiki.

Tun da zafin zafi tsakanin bayan wafer da saman tushe yana buƙatar wani matsa lamba, yawanci a cikin tsari na Torr da yawa, kuma matsi na aiki na ɗakin yana yawanci a cikin tsari na mTorr da yawa, matsa lamba a baya. na wafer ya fi girma fiye da matsa lamba a saman saman wafer, don haka ana buƙatar injin inji ko chuck na lantarki don matsayi da iyakance wafer.

Kayan aikin injiniya yana dogara da nauyin kansa da gefen wafer don cimma wannan aikin. Kodayake yana da fa'idodin tsari mai sauƙi da rashin jin daɗi ga kayan wafer, tasirin gefen wafer a bayyane yake, wanda ba shi da amfani ga tsananin sarrafa ƙwayoyin cuta. Saboda haka, a hankali an maye gurbinsa da chuck electrostatic a cikin tsarin masana'antar IC.

Don matakan da ba su da kula da zafin jiki na musamman, ana iya amfani da mara amfani, hanyar ɓoye lamba mara ƙima (babu bambance-bambancen matsa lamba tsakanin saman da ƙasa na wafer). Yayin aiwatar da PVD, za a ajiye rufin ɗakin da saman sassan da ke hulɗa da plasma kuma a rufe su. Lokacin da kaurin fim ɗin da aka ajiye ya wuce iyaka, fim ɗin zai tsage kuma ya bazu, yana haifar da matsalolin barbashi.

Sabili da haka, jiyya na saman sassa kamar rufi shine mabuɗin ƙaddamar da wannan iyaka. Yashi mai yashi da feshin aluminium hanyoyi ne guda biyu da aka saba amfani da su, manufarsu ita ce ƙara daɗaɗɗun saman don ƙarfafa haɗin gwiwa tsakanin fim ɗin da rufin rufin.

3.5 Ionization Kayan Aikin Turin Jiki

Tare da ci gaba da ci gaban fasahar microelectronics, girman fasalin yana zama ƙarami kuma ƙarami. Tun da fasahar PVD ba za ta iya sarrafa jagorancin juzu'i na barbashi ba, ikon PVD don shiga ta ramuka da kunkuntar tashoshi tare da ma'auni mai girma yana iyakance, yana ƙara ƙalubalanci aikace-aikacen faɗaɗa na fasahar PVD na gargajiya. A cikin tsari na PVD, yayin da yanayin yanayin ramin rami ya karu, ɗaukar hoto a ƙasa yana raguwa, yana samar da tsari mai kama da eaves a saman kusurwar sama, da kuma samar da mafi ƙarancin ɗaukar hoto a kusurwar ƙasa.

An ƙirƙiri fasahar jibgewar tururin jiki mai ionized don magance wannan matsalar. Ya fara yin plasmatizes karfen zarra da aka fantsama daga abin da aka nufa ta hanyoyi daban-daban, sannan kuma yana daidaita wutar lantarki da aka ɗora akan wafer don sarrafa alkibla da kuzarin ions ɗin ƙarfe don samun tsayayyen ƙarfin ƙarfe na ion don shirya fim na bakin ciki, ta haka yana inganta. ɗaukar hoto na kasan matakai na babban al'amari rabo ta ramuka da kunkuntar tashoshi.

Siffar fasalin fasahar plasma ƙarfe mai ionized shine ƙari na mitar mitar rediyo a cikin ɗakin. A lokacin aiwatarwa, ana kiyaye matsin lamba na ɗakin a cikin yanayin da ya dace (sau 5 zuwa 10 na matsa lamba na yau da kullun). A lokacin PVD, ana amfani da na'urar mitar rediyo don samar da yanki na plasma na biyu, a cikin abin da ƙaddamarwar plasma na argon yana ƙaruwa tare da haɓaka ƙarfin mitar rediyo da matsin gas. Lokacin da atom ɗin ƙarfe da ke tofawa daga abin da aka yi niyya suka wuce ta wannan yanki, suna yin hulɗa tare da babban adadin argon plasma don samar da ions ƙarfe.

Aiwatar da tushen RF a mai ɗaukar wafer (kamar chuck electrostatic) na iya ƙara mummunan ra'ayi akan wafer don jawo hankalin ions masu kyau na ƙarfe zuwa kasan ramin pore. Wannan kwatance karfe ion kwarara perpendicular zuwa wafer surface inganta mataki kasa ɗaukar hoto na babban al'amari rabo pores da kunkuntar tashoshi.

Mummunan son zuciya da ake amfani da shi ga wafer kuma yana haifar da ions don jefar da saman wafer (reverse sputtering), wanda ke raunana tsarin overhanging na bakin rami kuma ya watsa fim ɗin da aka ajiye a ƙasa a kan bangon gefe a sasanninta na kasan pore. tsagi, ta haka inganta matakin ɗaukar hoto a sasanninta.

3.6 Na'urorin Jiki na Ruwan Ruwan Halitta

Na'urar matsa lamba ta sinadarai (APCVD) tana nufin na'urar da ke fesa tushen amsawar iskar gaseous a koyaushe a kan saman wani abu mai zafi mai zafi a ƙarƙashin yanayi tare da matsi kusa da matsa lamba na yanayi, yana haifar da amsawar tushen amsa ta hanyar sinadarai a kan. da substrate surface, da dauki samfurin da aka ajiye a kan substrate surface don samar da wani bakin ciki fim.

Kayan aiki na APCVD shine farkon kayan aikin CVD kuma har yanzu ana amfani dashi sosai a cikin samar da masana'antu da binciken kimiyya. Ana iya amfani da kayan aikin APCVD don shirya fina-finai na bakin ciki irin su silicon crystal silicon, polycrystalline silicon, silicon dioxide, zinc oxide, titanium dioxide, gilashin phosphosilicate, da gilashin borophosphosilicate.

3.7 Kayayyakin Tushen Tushen Sinadarai Masu Rage Matsi

Ƙananan matsi na tururi na sinadarai (LPCVD) kayan aiki yana nufin kayan aiki waɗanda ke amfani da albarkatun gas don amsa sinadarai a saman wani abu mai ƙarfi a ƙarƙashin mai zafi (350-1100 ° C) da ƙananan matsa lamba (10-100mTorr), kuma da reactants ana ajiye a kan substrate surface don samar da wani bakin ciki fim. An haɓaka kayan aikin LPCVD akan tushen APCVD don haɓaka ingancin fina-finai na bakin ciki, haɓaka daidaituwar rarraba daidaitattun sigogi kamar kauri na fim da tsayayya, da haɓaka haɓakar samarwa.

Babban fasalinsa shine cewa a cikin yanayin filin zafi mai ƙarancin ƙarfi, iskar gas ɗin yana amsawa ta hanyar sinadarai a saman ma'aunin wafer, kuma ana adana samfuran amsawa a saman ƙasa don samar da fim na bakin ciki. Kayan aikin LPCVD yana da fa'ida a cikin shirye-shiryen fina-finai na bakin ciki masu inganci kuma ana iya amfani da su don shirya fina-finai na bakin ciki kamar silicon oxide, silicon nitride, polysilicon, silicon carbide, gallium nitride da graphene.

Idan aka kwatanta da APCVD, ƙananan yanayin amsawa na kayan aikin LPCVD yana ƙaruwa da ma'anar kyauta da kuma rarrabawar iskar gas a cikin ɗakin amsawa.

The dauki gas da kuma m gas kwayoyin a cikin dauki jam'iyya za a iya ko'ina rarraba a cikin wani gajeren lokaci, don haka ƙwarai inganta uniformity na fim kauri, resistivity uniformity da mataki ɗaukar hoto na fim, da kuma amfani da dauki iskar gas ma kadan. Bugu da ƙari, ƙananan yanayi kuma yana haɓaka saurin watsa abubuwan gas. Najasa da amsa ta-kayayyakin da aka bazu daga substrate za a iya fitar da su da sauri daga yankin amsawa ta hanyar iyaka, kuma iskar gas ɗin da sauri ta wuce ta iyakar Layer don isa saman ƙasa don amsawa, don haka yadda ya kamata ya hana kai-doping, shirya. fina-finai masu inganci tare da yankuna masu tsattsauran ra'ayi, da kuma inganta ingantaccen samarwa.

3.8 Ingantattun Kayan Aikin Tushin Sinadari na Plasma

Plasma enhanced chemical vapor deposition (PECVD) shine thin film deposition fasahar. A yayin aiwatar da aikin plasma, ana yin ionized precursor na gaseous a ƙarƙashin aikin plasma don ƙirƙirar ƙungiyoyi masu ban sha'awa, waɗanda ke yaduwa zuwa saman ƙasa sannan kuma su sami halayen sinadarai don kammala haɓakar fim ɗin.

Dangane da yawan ƙwayoyin plasma da aka yi amfani da su a cikin PECVD za a iya raba su zuwa nau'i biyu: plasma mitar rediyo (RF plasma) da kuma microwave plasma (Plassma Microwave). A halin yanzu, mitar rediyo da ake amfani da ita a masana'antar gabaɗaya 13.56MHz ne.

Gabatarwar plasma mitar rediyo yawanci ana kasu kashi biyu: capacitive coupling (CCP) da inductive coupling (ICP). Hanyar haɗakarwa mai ƙarfi yawanci hanya ce ta amsawar plasma kai tsaye; yayin da hanyar haɗin gwiwar inductive na iya zama hanyar plasma kai tsaye ko kuma hanyar plasma mai nisa.

A cikin ayyukan masana'antu na semiconductor, ana amfani da PECVD sau da yawa don haɓaka fina-finai na bakin ciki akan abubuwan da ke ɗauke da ƙarfe ko wasu sifofi masu zafin jiki. Misali, a fagen haɗin gwiwar ƙarfe na baya-baya na haɗaɗɗun da'irori, tun da tushen tushen, kofa da tsarin magudanar na'urar a cikin tsarin gaba-gaba, haɓakar fina-finai na bakin ciki a fagen haɗin gwiwar ƙarfe yana cikin batun. zuwa matsanancin ƙarancin kasafin kuɗi na thermal, don haka yawanci ana kammala shi tare da taimakon plasma. Ta hanyar daidaita ma'aunin tsarin plasma, ƙima, abun da ke tattare da sinadarai, abun ciki na ƙazanta, ƙaƙƙarfan inji da sigogin danniya na bakin ciki na fim ɗin da PECVD ta girma za'a iya daidaitawa da haɓakawa a cikin takamaiman kewayon.

3.9 Kayan Atomic Layer Deposition

Atomic Layer Deposition (ALD) fasaha ce ta sirarariyar adana fim wacce ke girma lokaci-lokaci a cikin nau'in Layer-monoatomic Layer. Halinsa shine cewa za'a iya daidaita kauri na fim ɗin da aka ajiye daidai ta hanyar sarrafa yawan hawan hawan girma. Ba kamar tsarin shigar da tururin sinadarai (CVD), magabatan biyu (ko sama da haka) a cikin tsarin ALD a madadin su ke wucewa ta saman ƙasa kuma ana keɓe su sosai ta hanyar tsabtace iskar gas.

Abubuwan da ke gaba biyu ba za su haɗu da haɗuwa a cikin lokacin iskar gas don mayar da martani ta hanyar sinadarai ba, amma kawai suna amsawa ta hanyar tallan sinadarai a saman ƙasa. A cikin kowane ALD sake zagayowar, adadin precursor adsorbed a kan substrate surface yana da alaka da yawa na aiki kungiyoyin a kan substrate surface. Lokacin da ƙungiyoyi masu amsawa a saman ƙasa suka ƙare, ko da an gabatar da wuce haddi na precursor, tallan sinadarai ba zai faru a saman ƙasa ba.

Ana kiran wannan tsarin amsawa a saman kai mai iyakancewa. Wannan tsarin tsarin yana sanya kauri daga cikin fim ɗin girma a cikin kowane sake zagayowar na ALD tsari akai, don haka ALD tsari yana da abũbuwan amfãni na daidai kauri iko da kyau fim mataki ɗaukar hoto.

3.10 Kayayyakin Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwaƙwalwa

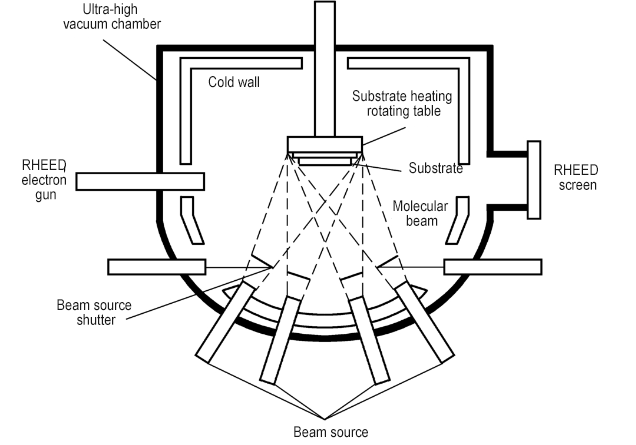

Tsarin Molecular Beam Epitaxy (MBE) yana nufin na'urar epitaxial wanda ke amfani da ɗayan ko fiye da ƙarfin makamashin atomic biam ko katako na ƙwayoyin cuta don fesa saman saman mai zafi a wani ɗan gudun hijira a ƙarƙashin matsananciyar matsananciyar yanayi, da kuma yin ƙaura da ƙaura a saman ƙasan ƙasa. zuwa epitaxially girma guda crystal bakin ciki fina-finai tare da crystal axis shugabanci na substrate abu. Gabaɗaya, a ƙarƙashin yanayin dumama ta tanderun jet tare da garkuwar zafi, tushen katako yana ƙirƙirar katako na atomic ko katako na ƙwayoyin cuta, kuma fim ɗin yana girma Layer by Layer tare da jagorar axis na kristal na kayan aikin.

Siffofinsa sune ƙananan zafin girma na epitaxial, kuma kauri, dubawa, abun da ke tattare da sinadarai da ƙarancin ƙazanta ana iya sarrafa shi daidai a matakin atomic. Ko da yake MBE ya samo asali ne daga shirye-shiryen fina-finai na semiconductor matsananci-bakin ciki guda ɗaya, aikace-aikacen sa yanzu ya fadada zuwa tsarin kayan aiki iri-iri kamar ƙarfe da insulating dielectrics, kuma yana iya shirya III-V, II-VI, silicon, silicon germanium (SiGe). ), graphene, oxides da fina-finai na halitta.

Tsarin ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar cuta (MBE) ya ƙunshi babban tsarin iska mai ƙarfi, tushen katako na ƙwayoyin cuta, tsarin gyara ƙasa da tsarin dumama, tsarin canja wurin samfurin, tsarin kulawa a cikin wurin, tsarin sarrafawa, da gwaji. tsarin.

Tsarin injin ya haɗa da famfunan injina (famfu na injina, famfo na ƙwayoyin ƙwayoyin cuta, famfo ion, da famfunan daɗaɗɗen ruwa, da dai sauransu) da kuma bawuloli daban-daban, waɗanda zasu iya haifar da yanayi mai girma na matsananci. Matsakaicin matakin da za a iya cimma gabaɗaya shine 10-8 zuwa 10-11 Torr. Tsarin injin yana da ɗakuna masu aiki guda uku, wato ɗakin alluran samfurin, ɗakin pretreatment da farfajiyar bincike, da ɗakin girma.

Ana amfani da ɗakin allura na samfurin don canja wurin samfurori zuwa duniyar waje don tabbatar da yanayin rashin tsabta na sauran ɗakunan; da pretreatment da surface analysis dakin ya haɗu da samfurin allura dakin da kuma girma dakin, kuma babban aikinsa shi ne don aiwatar da samfurin (high-zazzabi degassing don tabbatar da cikakken tsabta na substrate surface) da kuma yin na farko surface bincike a kan. samfurin tsaftacewa; ɗakin girma shine ainihin ɓangaren tsarin MBE, wanda ya ƙunshi tanderun tushe da madaidaicin taron rufewa, na'ura mai sarrafa samfurin, tsarin sanyaya, wani tunani mai girma na makamashin lantarki (RHEED), da tsarin kulawa a cikin wurin. . Wasu kayan aikin MBE na samarwa suna da saitunan ɗakunan girma da yawa. An nuna zane-zane na tsarin kayan aikin MBE a ƙasa:

MBE na silicon abu yana amfani da silicon high-tsarki a matsayin albarkatun kasa, girma a karkashin matsananci-high (10-10 ~ 10-11Torr) yanayi, da kuma girma zafin jiki ne 600 ℃ 900 ℃, tare da Ga (P-type) da Sb ( N-type) azaman tushen doping. Abubuwan da aka saba amfani da su kamar P, As da B ba safai ake amfani da su azaman tushen katako saboda suna da wahalar ƙafewa.

The dauki dakin na MBE yana da matsananci-high vacuum yanayi, wanda ƙara ma'ana free hanya na kwayoyin da kuma rage samu da hadawan abu da iskar shaka a saman kayan girma. Kayan epitaxial da aka shirya yana da kyakkyawan yanayin yanayin yanayi da daidaituwa, kuma ana iya yin shi a cikin tsarin multilayer tare da daban-daban doping ko kayan kayan daban-daban.

Fasaha ta MBE tana samun ci gaba mai-maituka na manyan yadudduka na epitaxial masu kauri tare da kauri guda ɗaya na atomic Layer, kuma haɗin tsakanin sassan epitaxial yana da tsayi. Yana haɓaka haɓakar semiconductor na III-V da sauran abubuwa masu yawa iri-iri. A halin yanzu, tsarin MBE ya zama kayan aiki na ci gaba don samar da sabon ƙarni na na'urorin microwave da na'urorin optoelectronic. Rashin hasara na fasahar MBE shine jinkirin girman girman fim, babban buƙatun injin, da manyan kayan aiki da farashin amfani da kayan aiki.

3.11 Tsarin Tashin Hankali na Epitaxy

Tsarin tururi na epitaxy (VPE) yana nufin na'urar haɓakar epitaxial wacce ke jigilar mahaɗan gaseous zuwa ma'auni kuma yana samun nau'in kayan kristal guda ɗaya tare da tsarin lattice iri ɗaya kamar substrate ta hanyar halayen sinadarai. Layin epitaxial na iya zama homoepitaxial Layer (Si/Si) ko heteroepitaxial Layer (SiGe/Si, SiC/Si, GaN/Al2O3, da dai sauransu). A halin yanzu, an yi amfani da fasahar VPE sosai a fagen shirye-shiryen nanomaterial, na'urorin wutar lantarki, na'urorin optoelectronic semiconductor, hasken rana photovoltaics, da kuma haɗakar da da'irori.

Hankula VPE hada da yanayi matsa lamba epitaxy da kuma rage matsa lamba epitaxy, matsananci-high injin injin tururi jibo, karfe Organic sinadaran tururi shaida, da dai sauransu The key maki a VPE fasaha ne dauki jam'iyya zane, gas kwarara yanayin da uniformity, zafin jiki uniformity da daidaici iko. kula da matsa lamba da kwanciyar hankali, sarrafa barbashi da lahani, da sauransu.

A halin yanzu, jagorancin ci gaba na tsarin kasuwanci na yau da kullum na VPE shine babban nauyin wafer, cikakken sarrafawa ta atomatik, da kuma kulawa na ainihi na yanayin zafi da girma. Tsarin VPE yana da sifofi uku: a tsaye, a kwance da silinda. Hanyoyin dumama sun haɗa da dumama juriya, dumama shigar da mitoci mai girma da dumama hasken infrared.

A halin yanzu, tsarin VPE galibi suna amfani da sifofin diski na kwance, waɗanda ke da halaye na daidaitaccen daidaituwa na ci gaban fim ɗin epitaxial da babban nauyin wafer. Tsarin VPE yawanci ya ƙunshi sassa huɗu: reactor, tsarin dumama, tsarin hanyar gas da tsarin sarrafawa. Saboda lokacin girma na GaAs da GaN fina-finan epitaxial yana da ɗan tsayi, dumama shigar da dumama da juriya ana amfani da su. A cikin silicon VPE, girman girman fim ɗin epitaxial mafi yawa yana amfani da dumama shigar; Ci gaban fim ɗin epitaxial na bakin ciki galibi yana amfani da dumama infrared don cimma manufar saurin hawan zafin jiki / faɗuwa.

3.12 Tsarin Epitaxy Tsarin Ruwa

Liquid Phase Epitaxy (LPE) tsarin yana nufin kayan haɓaka epitaxial wanda ke narkar da kayan da za a shuka (kamar Si, Ga, As, Al, da dai sauransu) da dopants (kamar Zn, Te, Sn, da sauransu) a cikin Karfe mai ƙaramin narkewa (kamar Ga, In, da sauransu), ta yadda solute ɗin ya cika ko ya cika a cikin sauran ƙarfi, sannan a tuntuɓi madaidaicin kristal guda ɗaya. tare da bayani, kuma solute yana haɗewa daga sauran ƙarfi ta hanyar kwantar da hankali a hankali, kuma wani nau'i na kayan kristal tare da tsarin kristal da lattice akai-akai mai kama da na substrate yana girma a saman substrate.

Hanyar LPE ta Nelson et al. a 1963. An yi amfani da girma Si bakin ciki fina-finai da guda crystal kayan, kazalika da semiconductor kayan kamar III-IV kungiyoyin da mercury cadmium telluride, kuma za a iya amfani da su yi daban-daban optoelectronic na'urorin, microwave na'urorin, semiconductor na'urorin da hasken rana Kwayoyin. .

——————————————————————————————————————————————————— ———————————-

Semicera na iya bayarwasassa graphite, taushi / m ji, silicon carbide sassa, CVD silicon carbide sassa, kumaSiC/TaC rufaffiyar sassatare da cikin kwanaki 30.

Idan kuna sha'awar samfuran semiconductor na sama,don Allah kar a yi shakka a tuntube mu a farkon lokaci.

Lambar waya: +86-13373889683

WhatsApp: +86-15957878134

Email: sales01@semi-cera.com

Lokacin aikawa: Agusta-31-2024