Wafers sune manyan albarkatun ƙasa don samar da haɗaɗɗun da'irori, na'urori masu hankali da na'urori masu ƙarfi. Fiye da 90% na haɗaɗɗun da'irori ana yin su akan tsafta mai inganci, wafers masu inganci.

Wafer kayan aiki kayan aiki yana nufin aiwatar da yin tsarki polycrystalline silicon kayan a cikin silicon guda crystal sanda kayan na wani diamita da kuma tsawon, sa'an nan kuma gabatar da silicon guda crystal sanda kayan zuwa jerin inji sarrafa, sinadaran magani da sauran matakai.

Kayan aikin da ke ƙera wafern siliki ko wafers na siliki na epitaxial waɗanda suka dace da wasu daidaiton geometric da buƙatun ingancin saman kuma suna ba da madaidaicin siliki da ake buƙata don masana'antar guntu.

Tsarin tsari na yau da kullun don shirya wafers na silicon tare da diamita na ƙasa da 200 mm shine:

Girman kristal guda ɗaya → truncation → mirgina diamita na waje → slicing → chamfering → niƙa → etching → samun → gogewa → tsaftacewa → epitaxy → marufi, da sauransu.

Babban tsarin gudana don shirya wafers na silicon tare da diamita na 300 mm shine kamar haka:

Girman kristal guda ɗaya → truncation → mirgine diamita na waje → slicing → chamfering → saman nika → etching → goge baki → goge fuska biyu → goge mai gefe guda → tsaftacewa ta ƙarshe → epitaxy/annealing → marufi, da sauransu.

1.Silicon abu

Silicon abu ne na semiconductor saboda yana da 4 valence electrons kuma yana cikin rukunin IVA na tebur na lokaci-lokaci tare da wasu abubuwa.

Adadin valence electrons a cikin silicon yana sanya shi daidai tsakanin mai gudanarwa mai kyau (1 valence electron) da insulator (8 valence electrons).

Ba a samun siliki mai tsafta a cikin yanayi kuma dole ne a fitar da shi kuma a tsarkake shi don ya zama mai tsarki isa ga masana'antu. Yawancin lokaci ana samuwa a cikin silica (silicon oxide ko SiO2) da sauran silicates.

Sauran nau'ikan SiO2 sun haɗa da gilashi, crystal mara launi, ma'adini, agate da idon cat.

Abu na farko da aka yi amfani da shi azaman semiconductor shine germanium a cikin 1940s da farkon 1950s, amma an maye gurbinsa da sauri da silicon.

An zaɓi siliki a matsayin babban kayan aikin semiconductor saboda manyan dalilai guda huɗu:

Yawan Abubuwan Silicon: Silicon ita ce sinadari na biyu mafi yawa a duniya, wanda ya kai kashi 25% na ɓawon burodin duniya.

Matsayi mafi girma na narkewa na kayan silicon yana ba da damar jurewar tsari mai faɗi: wurin narkewar silicon a 1412°C ya fi narkewar germanium a 937°C. Matsayi mafi girma yana ba da damar silicon don tsayayya da matakan zafin jiki.

Kayan siliki suna da kewayon zafin aiki mai faɗi;

Girman dabi'a na silicon oxide (SiO2): SiO2 abu ne mai inganci, kwanciyar hankali na lantarki kuma yana aiki azaman kyakkyawan shingen sinadarai don kare silicon daga gurɓataccen waje. Kwanciyar wutar lantarki yana da mahimmanci don guje wa ɗigowa tsakanin masu da'ira da ke kusa a cikin da'irori da aka haɗa. Ikon girma barga na bakin ciki na kayan SiO2 yana da mahimmanci ga kera na'urorin ƙarfe-oxide semiconductor (MOS-FET). SiO2 yana da irin wannan kaddarorin inji zuwa silicon, yana ba da damar sarrafa zafin jiki ba tare da wuce kima na wafer siliki ba.

2.Shirin wafer

Semiconductor wafers an yanke daga babban kayan semiconductor. Ana kiran wannan abu na semiconductor sandar crystal, wanda aka girma daga babban toshe na polycrystalline da kayan da ba a kwance ba.

Canza shingen polycrystalline zuwa babban kristal guda ɗaya da ba shi daidaitaccen yanayin kristal da adadin da ya dace na nau'in N-type ko nau'in P-doping ana kiransa girma crystal.

Mafi yawan fasahohin fasaha don samar da ingots silicon kristal guda ɗaya don shirye-shiryen wafer silicon shine hanyar Czochralski da hanyar narkewar yanki.

2.1 Hanyar Czochralski da Czochralski makera crystal makera

Hanyar Czochralski (CZ), wanda kuma aka sani da hanyar Czochralski (CZ), tana nufin tsarin canza narkakkar ruwan siliki na semiconductor-grade zuwa ingantaccen silicon-crystal silicon ingots tare da daidaitaccen daidaitawar lu'ulu'u kuma a sanya shi cikin nau'in N-type ko P- nau'in.

A halin yanzu, fiye da 85% na silicon crystal guda ɗaya ana girma ta hanyar amfani da hanyar Czochralski.

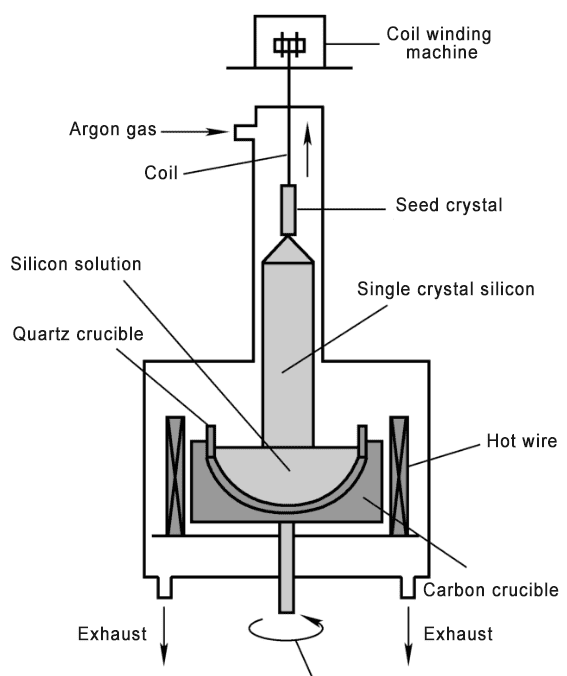

A Czochralski guda crystal makera yana nufin wani tsari kayan aiki da cewa narke high-tsarki polysilicon kayan cikin ruwa ta dumama a cikin wani rufaffiyar vacuum ko rare gas (ko inert gas) kariya muhalli, sa'an nan kuma recrystallizes su samar da guda crystal silicon kayan tare da wasu waje. girma.

Ka'idar aiki ta makera kristal guda ɗaya ita ce tsarin jiki na polycrystalline silicon abu recrystallizing zuwa guda crystal silicon abu a cikin ruwa jihar.

Za a iya raba tanderun crystal guda ɗaya na CZ zuwa sassa huɗu: jikin tanderun, tsarin watsawa na inji, tsarin dumama da tsarin kula da zafin jiki, da tsarin watsa gas.

Jikin tanderun ya haɗa da rami na tanderu, axis crystal axis, quartz crucible, cokali mai doping, murfin kristal iri, da taga kallo.

Ramin tanderun shine tabbatar da cewa zafin jiki a cikin tanderun yana rarraba daidai kuma yana iya watsar da zafi sosai; ana amfani da shaft crystal iri don fitar da kristal iri don motsawa sama da ƙasa da juyawa; ana sanya ƙazantattun abubuwan da ake buƙatar yin amfani da su a cikin cokali na doping;

Murfin kristal iri shine don kare kristal iri daga gurɓata. Ana amfani da tsarin watsawa na inji musamman don sarrafa motsin kristal iri da crucible.

Don tabbatar da cewa maganin silicon ba a oxidized ba, ana buƙatar digiri a cikin tanderu ya zama mai girma sosai, gabaɗaya ƙasa da 5 Torr, kuma tsarkakakken iskar gas ɗin da aka ƙara dole ne ya kasance sama da 99.9999%.

Ana amfani da wani yanki na silicon crystal guda ɗaya tare da daidaitawar kristal da ake so azaman kristal iri don haɓaka ingot silicon, kuma ingot ɗin siliki mai girma kamar kwafin kristal iri ne.

Yanayin mu'amala tsakanin narkakkar siliki da kristal iri kristal guda ɗaya yana buƙatar sarrafa daidai gwargwado. Waɗannan sharuɗɗan suna tabbatar da cewa ƙaramin siliki na siliki na iya yin daidai daidai da tsarin kristal iri kuma a ƙarshe ya girma zuwa babban ingot silicon kristal guda ɗaya.

2.2 Hanyar Narkewar Yanki da Yanki Narkewar Furnace Guda Daya

Hanyar yankin iyo (FZ) tana samar da ingots silicon crystal guda ɗaya tare da ƙarancin abun ciki na oxygen. Hanyar yankin iyo an haɓaka shi a cikin 1950s kuma yana iya samar da mafi kyawun siliki kristal guda ɗaya zuwa yau.

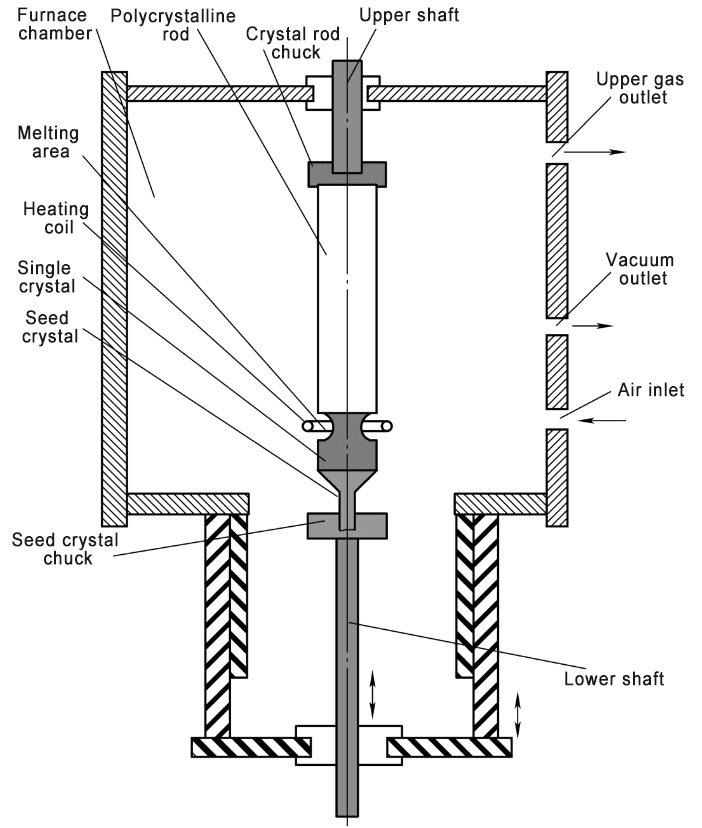

Wurin narkewa guda kristal tanderu yana nufin tanderun da ke amfani da ka'idar narkewar yanki don samar da yanki mai narkewa a cikin sandar polycrystalline ta wurin rufaffiyar yanayin zafi mai zafi na sandar tanderun polycrystalline a cikin babban injin injin ruwa ko ƙarancin ma'adini tube gas. yanayin kariya.

Kayan aiki wanda ke motsa sandar polycrystalline ko jikin dumama tanderun don matsar da yankin narkewa kuma a hankali ya sanya shi cikin sandar crystal guda ɗaya.

Halayen shirya sandunan kristal guda ɗaya ta hanyar narkewar yanki shine cewa ana iya inganta tsaftar sandunan polycrystalline a cikin aiwatar da crystallization cikin sandunan kristal guda ɗaya, kuma haɓakar doping na kayan sanda ya fi daidaituwa.

Nau'in narke nau'ikan murhun wuta guda ɗaya na kristal za a iya kasu kashi biyu: yankin iyo mai narke murhun wuta guda ɗaya wanda ya dogara da tashin hankali na ƙasa da yankin kwance na narkewa guda kristal tanderu. A aikace aikace, yankin narkewa guda kristal tanderun gabaɗaya yana ɗaukar yankin narkewa.

Wurin narkewar makera kristal guda ɗaya na iya shirya silikon kristal mai ƙarancin iskar oxygen mai ƙarfi mai ƙarfi ba tare da buƙatar crucible ba. An yafi amfani da shi don shirya high-resistivity (> 20kΩ · cm) guda crystal silicon da tsarkake yankin narkewa silicon. Ana amfani da waɗannan samfuran musamman wajen kera na'urorin wuta masu hankali.

The zone narkewa guda crystal makera kunshi wani makera dakin, wani babba shaft da ƙananan shaft (mechanical watsa part), wani crystal sanda Chuck, a iri crystal Chuck, wani dumama nada (high mita janareta), gas tashar jiragen ruwa (vacuum tashar jiragen ruwa,). mashigin iskar gas, babban kanti na gas), da sauransu.

A cikin tsarin ɗakin murhu, ana shirya wurare dabam dabam na ruwa. Ƙarshen ƙarshen ɓangaren sama na tanderun crystal guda ɗaya shine sandar lu'u-lu'u, wanda ake amfani da shi don manne sandar polycrystalline; Ƙarshen saman ƙwanƙarar ƙanƙara shine nau'in lu'u-lu'u na iri, wanda ake amfani dashi don manne kristal iri.

Ana ba da wutar lantarki mai girma zuwa ga dumama, kuma an kafa wani yanki mai narkewa a cikin sandar polycrystalline wanda ya fara daga ƙananan ƙarshen. A lokaci guda, gatari na sama da na ƙasa suna jujjuya su saukowa, ta yadda yankin narkewa ya zama crystallized zuwa kristal guda ɗaya.

Abubuwan da ake amfani da shi na yankin narkewa guda kristal tanderun shine cewa ba kawai zai iya inganta tsabtar kristal da aka shirya ba, har ma ya sa sandar doping girma ya zama mafi uniform, kuma sandar crystal guda ɗaya za a iya tsarkake ta hanyar matakai masu yawa.

Rashin hasara na yankin narkewar makera kristal ɗaya shine tsadar tsari da ƙananan diamita na kristal da aka shirya. A halin yanzu, matsakaicin diamita na kristal guda ɗaya wanda za'a iya shirya shine 200mm.

Gabaɗayan tsayin yanki na narkewa guda ɗaya kayan aikin murhu na kristal yana da tsayi, kuma bugun saman gatari da na ƙasa yana da tsayi, don haka ana iya girma sandunan kristal guda ɗaya.

3. Wafer aiki da kayan aiki

Sanda kristal yana buƙatar tafiya ta jerin matakai don samar da siliki wanda ya dace da bukatun masana'antar semiconductor, wato wafer. Tushen tsarin sarrafawa shine:

Tumbling, yankan, slicing, wafer annealing, chamfering, nika, polishing, tsaftacewa da marufi, da dai sauransu.

3.1 Wafer Annealing

A cikin aiwatar da masana'anta polycrystalline silicon da silicon Czochralski, silicon crystal guda ɗaya ya ƙunshi oxygen. A wani yanayin zafi, iskar oxygen da ke cikin silicon crystal ɗin guda ɗaya zai ba da gudummawar electrons, kuma oxygen ɗin zai canza zuwa masu ba da iskar oxygen. Waɗannan na'urorin lantarki za su haɗu da ƙazanta a cikin wafer siliki kuma suna shafar juriya na wafer silicon.

Murnar murɗawa: tana nufin tanderun da ke ɗaga zafin wuta a cikin tanderun zuwa 1000-1200 ° C a cikin yanayin hydrogen ko argon. Ta hanyar yin dumi da sanyaya, iskar oxygen da ke kusa da farfajiyar wafer siliki mai gogewa yana canzawa kuma an cire shi daga samansa, yana haifar da iskar oxygen zuwa hazo da Layer.

Kayan aiki na tsari wanda ke narkar da ƙananan lahani akan saman siliki wafers, yana rage yawan ƙazanta kusa da saman wafern siliki, yana rage lahani, da kuma samar da wani yanki mai tsabta a saman siliki wafers.

Ana kuma kiran murhun murhun wuta mai zafi saboda yawan zafinta. Har ila yau, masana'antar ta kira tsarin hana wafer siliki.

Silicon wafer annealing makera ya kasu zuwa:

- Annealing tanderu;

-Tanderun murɗawa a tsaye;

-Tanderu mai saurin kashe wuta.

Babban bambanci tsakanin murhun murɗawa a kwance da tanderun murɗawa a tsaye shine jagorar shimfiɗar ɗakin amsawa.

Wurin amsawa na murhun murɗawa a kwance an tsara shi a kwance, kuma ana iya loda wani nau'i na wafern siliki a cikin ɗakin amsawar tanderun da ke murƙushe wutar lantarki a lokaci guda. Lokacin daɗaɗawa yawanci shine mintuna 20 zuwa 30, amma ɗakin amsawa yana buƙatar tsawon lokacin dumama don isa yanayin zafin da ake buƙata ta hanyar cirewa.

Tsarin tanderun murɗawa a tsaye kuma yana ɗaukar hanyar ɗaukar nau'ikan wafers na siliki a lokaci guda a cikin ɗakin amsawar tanderun da ke ɓoye don ba da magani. Gidan amsawa yana da shimfidar tsari na tsaye, wanda ke ba da damar sanya wafers na silicon a cikin jirgin ruwa na quartz a cikin yanayin kwance.

A lokaci guda kuma, tun da kwale-kwalen ma'adini na iya jujjuya gabaɗaya a cikin ɗakin amsawa, yanayin zafi na ɗabi'ar amsawa daidai ne, rarraba zafin jiki akan wafer siliki daidai ne, kuma yana da kyawawan halaye na bacin rai. Duk da haka, farashin tsari na tanderun murɗawa a tsaye ya fi na tanderun da ke kwance a kwance.

Tanderu mai saurin ruɗewa yana amfani da fitilar halogen tungsten don ɗora wafer siliki kai tsaye, wanda zai iya samun saurin dumama ko sanyaya a cikin kewayon 1 zuwa 250°C/s. Adadin dumama ko sanyaya yana da sauri fiye da na tanderun murɗawa na gargajiya. Yana ɗaukar ƴan daƙiƙa kaɗan kawai don dumama zafin ɗakin amsawa zuwa sama da 1100°C.

——————————————————————————————————————————————————— --

Semicera na iya bayarwasassa graphite,taushi / m ji,silicon carbide sassa, CVD silicon carbide sassa, kumaSiC/TaC rufaffiyar sassatare da cikakken tsari na semiconductor a cikin kwanaki 30.

Idan kuna sha'awar samfuran semiconductor na sama, don Allah kar a yi shakka a tuntube mu a farkon lokaci.

Lambar waya: +86-13373889683

WhatsApp: +86-15957878134

Email: sales01@semi-cera.com

Lokacin aikawa: Agusta-26-2024