Epitaxial Layer shine takamaiman fim ɗin kristal guda ɗaya wanda aka girma akan wafer ta hanyar tsarin epitaxial, kuma wafer ɗin substrate da fim ɗin epitaxial ana kiransa wafer epitaxial. Ta hanyar haɓaka Layer na silicon carbide epitaxial a kan madaidaicin silin carbide substrate, ana iya ƙara shirya wafer ɗin siliki mai kama da epitaxial wafer zuwa cikin Schottky diodes, MOSFETs, IGBTs da sauran na'urorin wuta, waɗanda 4H-SiC mafi yawan amfani da su.

Saboda nau'ikan masana'anta daban-daban na na'urar wutar lantarki ta silicon carbide da na'urar wutar lantarki ta gargajiya, ba za a iya ƙirƙira ta kai tsaye akan siliki carbide guda crystal abu. Ƙarin ingantattun kayan epitaxial dole ne a girma a kan madaidaicin kristal guda ɗaya, kuma dole ne a kera na'urori daban-daban akan Layer epitaxial. Sabili da haka, ingancin launi na epitaxial yana da babban tasiri akan aikin na'urar. Inganta aikin na'urorin wutar lantarki daban-daban kuma yana gabatar da buƙatu masu girma don kauri na Layer epitaxial, maida hankali kan doping da lahani.

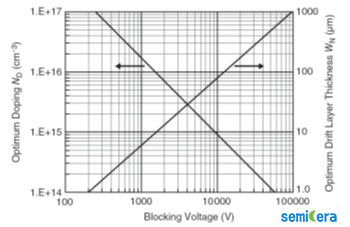

FIG. 1. Dangantaka tsakanin maida hankali na doping da kauri na epitaxial Layer na na'urar unipolar da kuma toshe ƙarfin lantarki

Hanyoyin shirye-shiryen na SIC epitaxial Layer sun haɗa da hanyar haɓakar evaporation, haɓakar ruwa lokaci epitaxial girma (LPE), kwayoyin katako epitaxial girma (MBE) da kuma sinadaran tururi (CVD). A halin yanzu, sinadari mai tururi (CVD) ita ce babbar hanyar da ake amfani da ita don yawan samarwa a masana'antu.

| Hanyar shiri | Abvantbuwan amfãni daga cikin tsari | Rashin hasara na tsari |

|

Girman Matsayin Liquid Epitaxial

(LPE)

|

Abubuwan buƙatun kayan aiki masu sauƙi da hanyoyin haɓaka ƙananan farashi. |

Yana da wuya a sarrafa yanayin yanayin yanayin Layer na epitaxial. Kayan aiki ba zai iya ɗaukar wafers da yawa a lokaci guda ba, yana iyakance yawan samarwa. |

|

Girman Girman Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararrun Ƙwararru (MBE)

|

SiC crystal epitaxial yadudduka daban-daban za a iya girma a ƙananan yanayin zafi |

Bukatun buƙatun kayan aiki suna da tsada kuma suna da tsada. Jinkirin girma na Layer epitaxial |

|

Zuba Ruwan Kemikal (CVD) |

Hanya mafi mahimmanci don samar da taro a masana'antu. Ana iya sarrafa ƙimar girma daidai lokacin da girma yadudduka na epitaxial mai kauri. |

SiC epitaxial layers har yanzu suna da lahani iri-iri waɗanda ke shafar halayen na'ura, don haka tsarin haɓakar epitaxial na SiC yana buƙatar ci gaba da inganta shi.TaCda ake bukata, duba SemiceraTaC samfurin) |

|

Hanyar girma ta evaporation

|

Yin amfani da kayan aiki iri ɗaya kamar SiC crystal ja, tsarin ya ɗan bambanta da ja na crystal. Balagagge kayan aiki, low cost |

Rashin rashin daidaituwa na SiC yana sa ya zama da wahala a yi amfani da evaporation don girma ingantattun yadudduka na epitaxial. |

FIG. 2. Kwatanta manyan hanyoyin shirye-shirye na Layer epitaxial

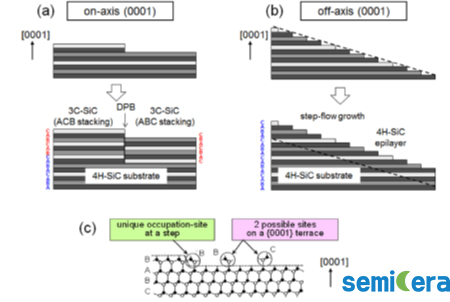

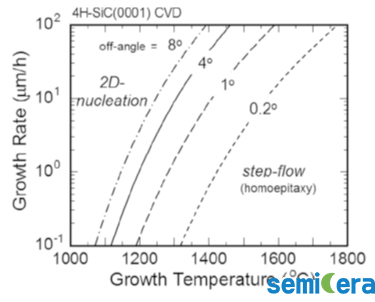

A kan kashe-axis {0001} tare da wani madaidaicin kusurwa, kamar yadda aka nuna a cikin hoto 2(b), girman matakin matakin ya fi girma, kuma girman saman matakin ya yi ƙarami, kuma ƙirar ƙira ba ta da sauƙi. faruwa a saman mataki, amma sau da yawa yana faruwa a wurin haɗuwa na mataki. A wannan yanayin, akwai maɓallin nucleating guda ɗaya kawai. Sabili da haka, Layer epitaxial na iya yin daidaitaccen tsari na stacking na substrate, don haka kawar da matsalar zaman tare masu yawa.

FIG. 3. Tsarin tsari na jiki na 4H-SiC mataki iko epitaxy hanya

FIG. 4. Mahimman yanayi don ci gaban CVD ta hanyar 4H-SiC mataki-sarrafa tsarin epitaxy

FIG. 5. Kwatanta ƙimar girma a ƙarƙashin tushen silicon daban-daban a cikin 4H-SiC epitaxy

A halin yanzu, fasahar epitaxy ta silicon carbide tana da ɗan girma a cikin ƙananan aikace-aikacen lantarki da matsakaici (kamar na'urorin 1200 volt). A kauri uniformity, doping maida hankali uniformity da lahani rarraba epitaxial Layer iya isa in mun gwada da kyau matakin, wanda zai iya m saduwa da bukatun tsakiyar da low irin ƙarfin lantarki SBD (Schottky diode), MOS (karfe oxide semiconductor filin sakamako transistor), JBS ( junction diode) da sauran na'urori.

Duk da haka, a fagen matsanancin matsin lamba, wafers na epitaxial har yanzu suna buƙatar shawo kan kalubale da yawa. Misali, ga na'urorin da suke buƙatar jure wa 10,000 volts, kauri na epitaxial Layer yana buƙatar kusan 100μm. Idan aka kwatanta da ƙananan na'urori masu ƙarfin lantarki, kauri na epitaxial Layer da daidaitattun abubuwan da ake amfani da su na doping sun bambanta da yawa, musamman ma daidaitattun matakan doping. A lokaci guda, lahani na triangle a cikin epitaxial Layer zai kuma lalata gaba ɗaya aikin na'urar. A cikin aikace-aikace masu ƙarfin ƙarfin lantarki, nau'ikan na'urori suna yin amfani da na'urorin bipolar, waɗanda ke buƙatar ƴan tsiraru tsawon rayuwa a cikin epitaxial Layer, don haka ana buƙatar inganta tsarin don inganta rayuwar tsirarun.

A halin yanzu, filaye na cikin gida ya fi inci 4 da inci 6, kuma adadin manyan silin carbide epitaxy na girma yana ƙaruwa kowace shekara. Girman takardar siliki carbide epitaxial an fi iyakance shi da girman silin carbide substrate. A halin yanzu, 6-inch silicon carbide substrate an sayar da shi, don haka silicon carbide epitaxial a hankali yana canzawa daga inci 4 zuwa inci 6. Tare da ci gaba da haɓaka fasahar shirye-shiryen siliki carbide da haɓaka iya aiki, farashin siliki carbide substrate yana raguwa a hankali. A cikin abun da ke ciki na farashin takardar epitaxial, ƙirar tana da fiye da 50% na farashi, don haka tare da raguwar farashin ma'auni, ana kuma sa ran farashin siliki na siliki na epitaxial ya ragu.

Lokacin aikawa: Juni-03-2024