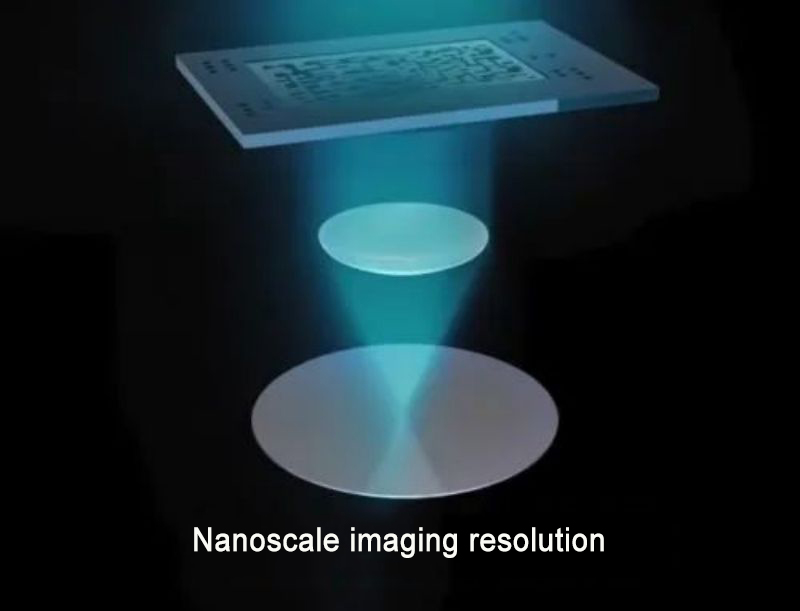

Daga cikin dukkan matakai da ke tattare da ƙirƙirar guntu, ƙaddarar ƙarshe nawaferza a yanke shi cikin mutun ɗaya kuma a haɗa shi a cikin ƙananan kwalaye da aka rufe tare da ƴan filaye kaɗan kawai fallasa. Za a kimanta guntu bisa ga bakin kofa, juriya, halin yanzu, da ƙimar ƙarfin lantarki, amma ba wanda zai yi la'akari da bayyanarsa. A lokacin aikin masana'antu, muna maimaita wafer don cimma daidaitaccen tsari, musamman ga kowane mataki na hoto. ThewaferDole ne saman ya kasance mai lebur sosai saboda, yayin da aikin kera guntu ke raguwa, ruwan tabarau na injin photolithography yana buƙatar cimma ƙuduri na sikelin nanometer ta hanyar haɓaka buɗewar lamba (NA) na ruwan tabarau. Koyaya, wannan lokaci guda yana rage zurfin mayar da hankali (DoF). Zurfin hankali yana nufin zurfin cikin abin da tsarin gani zai iya kula da hankali. Don tabbatar da cewa hoton photolithography ya kasance a bayyane kuma a cikin mayar da hankali, bambancin saman nawaferdole ne ya fada cikin zurfin hankali.

A cikin sauƙi, na'urar daukar hoto tana sadaukar da ikon mayar da hankali don inganta daidaiton hoto. Misali, injunan hoto na sabon ƙarni na EUV suna da buɗaɗɗen lamba na 0.55, amma zurfin mayar da hankali shine kawai 45 nanometers, tare da mafi ƙarancin kewayon hoto mafi kyau yayin daukar hoto. Idan dawaferba lebur, yana da m kauri, ko surface undulations, shi zai haifar da al'amurran da suka shafi a lokacin photolithography a high da ƙananan maki.

Photolithography ba shine kawai tsari da ke buƙatar santsi bawaferfarfajiya. Yawancin sauran hanyoyin sarrafa guntu kuma suna buƙatar walƙiya wafer. Misali, bayan rigar etching, ana buƙatar polishing don santsin daɗaɗɗen saman don rufewa da sakawa na gaba. Bayan keɓewar maɓalli mai zurfi (STI), ana buƙatar gogewa don daidaita silikon dioxide da ya wuce gona da iri da kammala cika mahara. Bayan sanya ƙarfe, ana buƙatar goge goge don cire ɗimbin yadudduka na ƙarfe da kuma hana gajerun da'irori na na'ura.

Don haka, haifuwar guntu ta ƙunshi matakai masu gogewa da yawa don rage ƙaƙƙarfan wafer da bambance-bambancen saman da cire wuce haddi daga saman. Bugu da ƙari, lahani na saman da ya haifar da al'amurran tsari daban-daban akan wafer sau da yawa kawai suna bayyana bayan kowane mataki na gogewa. Don haka, injiniyoyin da ke da alhakin goge goge suna ɗaukar nauyi mai mahimmanci. Su ne alkaluma na tsakiya a cikin tsarin kera guntu kuma galibi suna ɗaukar laifi a tarurrukan samarwa. Dole ne su kasance ƙware a cikin rigar etching da fitarwa ta zahiri, a matsayin manyan dabarun goge goge a masana'antar guntu.

Menene hanyoyin goge gogen wafer?

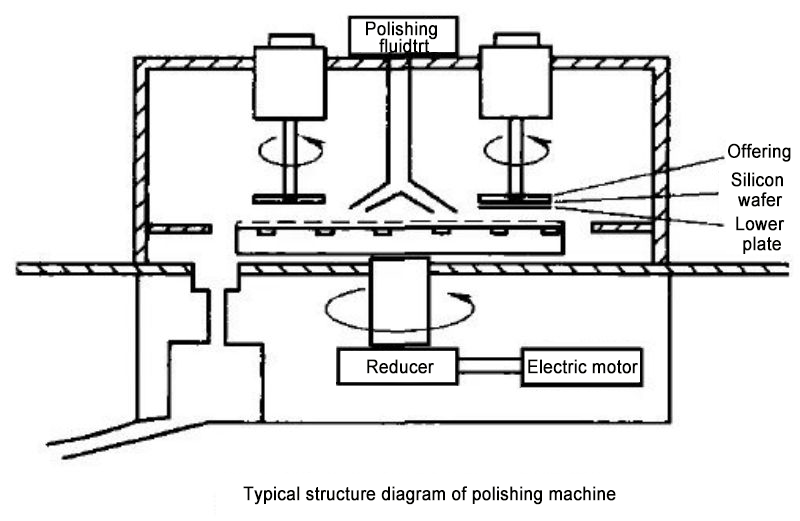

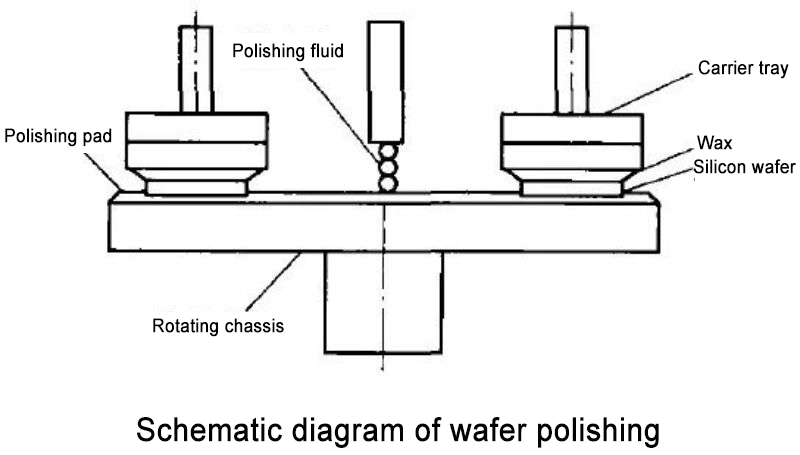

Ana iya rarraba hanyoyin goge goge zuwa manyan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'in tsiro)) na aiwatar da aikin shimfidar shimfidar shimfidar shimfidar shimfidar shimfidar shimfidar wurare guda uku bisa ka`idojin ma`amala tsakanin ruwan goge baki da saman wafer silicon:

1. Hanyar Gyaran Injini:

Gyaran injina yana kawar da fitattun saman da aka goge ta hanyar yankan da nakasar filastik don cimma ruwa mai santsi. Kayan aikin gama gari sun haɗa da duwatsun mai, ƙafafun ulu, da takarda mai yashi, waɗanda aka fara sarrafa su da hannu. Sashe na musamman, kamar saman jikin jujjuyawa, na iya amfani da kayan aikin juyawa da sauran kayan aikin taimako. Don saman da ke da ingantattun buƙatu, ana iya amfani da hanyoyin goge goge masu kyau. Super-lafiya polishing yana amfani da kayan aikin abrasive na musamman, waɗanda, a cikin wani ruwa mai gogewa mai ɗauke da abrasive, ana matse shi sosai akan saman kayan aikin kuma ana jujjuya shi cikin babban sauri. Wannan dabarar za ta iya cimma ƙarancin ƙasa na Ra0.008μm, mafi girma tsakanin duk hanyoyin gogewa. Ana yawan amfani da wannan hanyar don ƙirar ruwan tabarau na gani.

2. Hanyar Polishing Chemical:

gyare-gyaren sinadarai ya ƙunshi fifikon narkar da ƙananan abubuwan haɓakawa akan saman kayan a cikin matsakaicin sinadari, yana haifar da ƙasa mai santsi. Babban abũbuwan amfãni daga wannan hanya ne rashin bukatar hadaddun kayan aiki, da ikon goge hadaddun workpieces, da damar goge da yawa workpieces a lokaci guda tare da high dace. Babban batu na gogewar sinadarai shine samar da ruwa mai gogewa. Ƙunƙarar saman da aka samu ta hanyar gogewa sinadarai yawanci dubun micrometers ne.

3. Hanyar Gyaran Kankanin Sinadari (CMP):

Kowane ɗayan hanyoyin gogewa guda biyu na farko yana da fa'idodi na musamman. Haɗa waɗannan hanyoyin guda biyu na iya samun ƙarin sakamako a cikin tsari. Chemical inji polishing hada inji gogayya da sinadaran lalata tafiyar matakai. A lokacin CMP, sinadaran reagents a cikin polishing ruwa oxidize da goge substrate abu, forming wani taushi oxide Layer. Ana cire wannan Layer oxide ta hanyar jujjuyawar inji. Maimaita wannan hadawan abu da iskar shaka da na inji kau tsari cimma tasiri polishing.

Kalubale na Yanzu da Batutuwa a cikin Gyaran Injin Kayan Kemikal (CMP):

CMP yana fuskantar ƙalubale da batutuwa da yawa a fagagen fasaha, tattalin arziki, da dorewar muhalli:

1) Tsari Tsari: Samun babban daidaito a cikin tsarin CMP ya kasance mai wahala. Ko da a cikin layin samarwa iri ɗaya, ƙananan bambance-bambance a cikin sigogin tsari tsakanin batches ko kayan aiki daban-daban na iya shafar daidaiton samfurin ƙarshe.

2) Daidaitawa zuwa Sabbin Kayayyaki: Kamar yadda sabbin kayan ke ci gaba da fitowa, dole ne fasahar CMP ta dace da halayen su. Wasu ci-gaba kayan ƙila ba za su dace da tsarin CMP na gargajiya ba, suna buƙatar haɓaka ƙarin ruwan goge goge da goge goge.

3) Tasirin Girman: Kamar yadda ma'aunin na'ura na semiconductor ke ci gaba da raguwa, al'amurran da suka haifar da girman girman sun zama mafi mahimmanci. Ƙananan girma suna buƙatar mafi girman shimfidar ƙasa, yana buƙatar ƙarin ingantattun hanyoyin CMP.

4) Sarrafa ƙimar Cire Kayan Abu: A wasu aikace-aikace, daidaitaccen sarrafa adadin cire kayan don kayan daban-daban yana da mahimmanci. Tabbatar da daidaiton farashin cirewa a cikin yadudduka daban-daban yayin CMP yana da mahimmanci don kera na'urori masu inganci.

5) Abokan Muhalli: Ruwan goge-goge da abrasives da aka yi amfani da su a cikin CMP na iya ƙunsar abubuwan da ke cutar da muhalli. Bincike da haɓaka ƙarin hanyoyin da ke da alaƙa da muhalli da dorewar hanyoyin CMP da kayan ƙalubale ne masu mahimmanci.

6) Hankali da Aiki da kai: Yayin da hankali da matakin sarrafa kansa na tsarin CMP ke haɓaka sannu a hankali, dole ne su ci gaba da jure wa hadaddun yanayin samarwa masu rikitarwa. Samun manyan matakan sarrafa kansa da kuma sa ido na hankali don inganta ingantaccen samarwa ƙalubale ne da ke buƙatar magancewa.

7) Gudanar da Kuɗi: CMP ya ƙunshi manyan kayan aiki da farashin kayan aiki. Masu masana'anta suna buƙatar haɓaka aikin tsari yayin ƙoƙarin rage farashin samarwa don kula da gasa kasuwa.

Lokacin aikawa: Juni-05-2024