Silicon nitride (Si₃N₄) tukwane, a matsayin ci-gaba tukwane na tsarin, suna da kyawawan kaddarorin irin su juriya mai ƙarfi, ƙarfi mai ƙarfi, ƙarfin ƙarfi, ƙarfi mai ƙarfi, juriya mai rarrafe, juriya na iskar shaka, da juriya. Bugu da ƙari, suna ba da ingantaccen juriya na zafin zafi, kaddarorin dielectric, haɓakar yanayin zafi mai ƙarfi, da ingantaccen aikin watsa igiyoyin lantarki mai saurin mitoci. Waɗannan ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun abubuwa ke sa su yi amfani da su sosai a cikin hadaddun kayan gini, musamman a sararin samaniya da sauran manyan fasahohin fasaha.

Koyaya, Si₃N₄, kasancewa fili mai ƙarfi tare da haɗin gwiwa mai ƙarfi, yana da tsayayyen tsari wanda ke sa sintering zuwa babban yawa mai wahala ta hanyar yaduwar ƙasa mai ƙarfi kaɗai. Don inganta sintering, sintering taimakon, kamar karfe oxides (MgO, CaO, Al₂O₃) da rare earth oxides (Yb₂O₃, Y₂O₃, Lu₂O₃, CeO₂), ana kara don sauƙaƙe densification ta hanyar ruwa-lokaci sintering inji.

A halin yanzu, fasahar na'urar semiconductor na duniya tana ci gaba zuwa mafi girman ƙarfin lantarki, manyan igiyoyin ruwa, da mafi girman ƙarfin ƙarfi. Bincike kan hanyoyin ƙirƙirar yumbu na Si₃N₄ yana da yawa. Wannan labarin yana gabatar da matakai na sintering waɗanda ke inganta haɓakar ƙima da ƙayyadaddun kayan aikin injin silicon nitride yumbura.

Hanyoyin Sintering gama gari don Si₃N₄ Ceramics

Kwatanta Ayyuka don Si₃N₄ Ceramics da aka Shirya ta Hanyoyi daban-daban na Sintering

1. Reactive Sintering (RS):Reactive sintering ita ce hanya ta farko da aka yi amfani da ita don shirya Si₃N₄ yumbura a masana'antu. Yana da sauƙi, mai tsada, kuma yana iya ƙirƙirar sifofi masu rikitarwa. Duk da haka, yana da tsayin daka na samar da kayayyaki, wanda ba shi da amfani ga samar da sikelin masana'antu.

2. Rashin Matsi (PLS):Wannan shine mafi mahimmanci kuma mafi sauƙi tsarin sintering. Koyaya, yana buƙatar si₃N₄ albarkatun ƙasa masu inganci kuma galibi yana haifar da yumbu tare da ƙarancin ƙima, raguwa mai mahimmanci, da yanayin fashe ko nakasa.

3. Zafafan Mabambantan Sintering (HP):Aikace-aikacen matsa lamba na injin uniaxial yana ƙara ƙarfin tuƙi don sintiri, yana ba da damar samar da yumbu masu yawa a yanayin zafi 100-200 ° C ƙasa da waɗanda aka yi amfani da su a cikin sintering mara ƙarfi. Ana amfani da wannan hanyar yawanci don ƙirƙira yumbu mai siffa mai sauƙi mai sauƙi amma yana da wahala a cika kauri da buƙatun siffa don kayan ƙasa.

4. Spark Plasma Sintering (SPS):SPS ana siffanta shi da saurin rarrabuwa, tace hatsi, da rage yawan zafin jiki. Koyaya, SPS na buƙatar saka hannun jari mai mahimmanci a cikin kayan aiki, kuma shirye-shiryen babban ƙarfin wutar lantarki Si₃N₄ ceramics ta hanyar SPS har yanzu yana cikin matakin gwaji kuma har yanzu ba a haɓaka masana'antu ba.

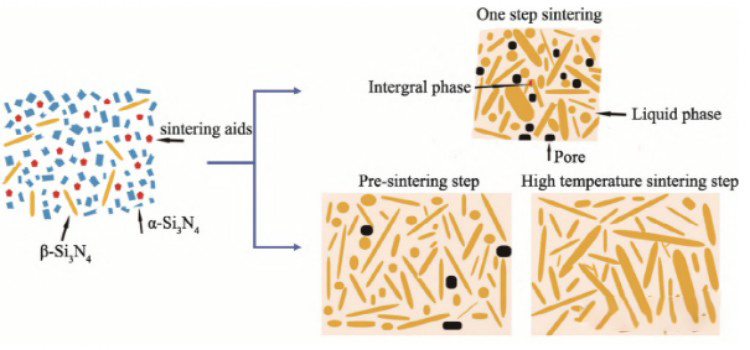

5. Haɓakar Gas-Matsi (GPS):Ta hanyar yin amfani da iskar gas, wannan hanya ta hana lalata yumbura da asarar nauyi a babban yanayin zafi. Yana da sauƙi don samar da yumbu masu yawa kuma yana ba da damar samar da tsari. Duk da haka, tsarin sintirin iskar gas-mataki-mataki ɗaya yana gwagwarmaya don samar da kayan aikin tsari tare da launi na ciki da waje iri ɗaya da tsari. Yin amfani da matakai biyu ko matakai masu yawa na sintering na iya rage yawan abubuwan oxygen na intergranular, inganta haɓakar zafi, da haɓaka kaddarorin gaba ɗaya.

Duk da haka, yawan zafin jiki na matakan matsi na iskar gas mai hawa biyu ya sa binciken da aka yi a baya ya mayar da hankali kan shirya Si₃N₄ yumbura mai ƙarfi tare da ƙarfin zafin jiki mai ƙarfi da ƙarfin lankwasa yanayin ɗaki. Bincike akan Si₃N₄ yumbura tare da cikakkun kaddarorin inji da kaddarorin inji mai zafi yana da iyaka.

Hanyar Sintering Mataki Biyu-Matsi-Gas don Si₃N₄

Yang Zhou da takwarorinsa na jami'ar fasaha ta Chongqing sun yi amfani da tsarin ba da agajin da ya kai 5 wt.% Yb₂O₃ + 5 wt.% Al₂O₃ don shirya yumbu na Si₃N₄ ta amfani da matakai guda daya da mataki biyu na sarrafa iskar gas a zazzabi na 1800C. Si₃N₄ tukwane da aka samar ta hanyar sintering mataki-mataki biyu yana da mafi girma yawa da ingantattun kaddarorin inji. Abubuwan da ke biyowa suna taƙaita tasirin matakai guda ɗaya da matakan iskar gas-mataki-mataki akan microstructure da kaddarorin injin Si₃N₄ abubuwan yumbu.

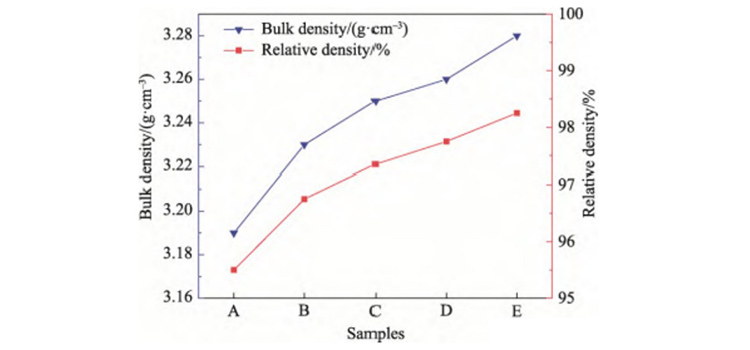

Dnsity Tsarin ɗimbin yawa na Si₃N₄ yawanci ya ƙunshi matakai uku, tare da zoba tsakanin matakan. Mataki na farko, sake tsara ɓangarorin, da mataki na biyu, narkar da hazo, sune mafi mahimmancin matakan ƙima. Isashen lokacin amsawa a cikin waɗannan matakan yana inganta haɓaka samfurin sosai. Lokacin da pre-sintering zafin jiki na biyu-mataki sintering tsari aka saita zuwa 1600 ° C, β-Si₃N₄ hatsi samar da wani tsari da kuma haifar da rufaffiyar pores. Bayan pre-sintering, ƙarin dumama a karkashin high zafin jiki da nitrogen matsa lamba inganta ruwa-lokaci kwarara da kuma cika, wanda taimaka kawar da rufaffiyar pores, kara inganta yawa na Si₃N₄ tukwane. Sabili da haka, samfurorin da aka samar ta hanyar matakai guda biyu suna nuna girman girma da ƙananan dangi fiye da waɗanda aka samar ta hanyar ƙwanƙwasa mataki ɗaya.

Mataki da Microstructure Lokacin sintering mataki ɗaya, lokacin da ake akwai don sake tsara ɓangarorin da rarraba iyakokin hatsi yana iyakance. A cikin matakai biyu na sintering tsari, mataki na farko ana gudanar da shi a cikin ƙananan zafin jiki da ƙananan iskar gas, wanda ke ƙara lokacin sake tsara kwayoyin halitta kuma yana haifar da mafi girma hatsi. Ana ƙara yawan zafin jiki zuwa matakin zafi mai zafi, inda hatsi ke ci gaba da girma ta hanyar ripening na Ostwald, yana samar da babban adadin Si₃N₄ yumbura.

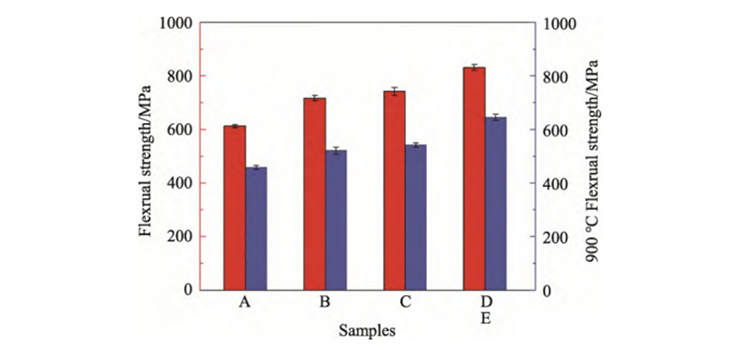

Kayayyakin injina Tausasawa na tsaka-tsakin lokaci a yanayin zafi shine babban dalilin rage ƙarfi. A cikin ƙwanƙwasa mataki ɗaya, haɓakar ƙwayar hatsi mara kyau yana haifar da ƙananan pores tsakanin hatsi, wanda ya hana gagarumin ci gaba a cikin ƙarfin zafin jiki. Duk da haka, a cikin matakai biyu na sintering tsari, gilashin lokaci, wanda aka rarraba daidai a cikin iyakokin hatsi, da kuma nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i) yana haɓaka ƙarfin intergranular,wanda ya haifar da ƙarfin jujjuya yanayin zafi mai girma.

A ƙarshe, ɗaukar tsayin daka yayin sintering na mataki ɗaya na iya yadda ya kamata ya rage porosity na ciki da cimma daidaitaccen launi da tsari na ciki amma yana iya haifar da ci gaban hatsi mara kyau, wanda ke lalata wasu kaddarorin injina. Ta hanyar amfani da tsarin sintering mataki biyu-ta yin amfani da pre-sintering low-zazzabi don tsawaita lokacin sake tsarawa da zafin jiki don haɓaka haɓakar hatsi iri ɗaya-Si₃N₄ yumbu tare da ƙarancin dangi na 98.25%, microstructure uniform, da ingantaccen kaddarorin inji. za a iya samun nasarar shiryawa.

| Suna | Substrate | Epitaxial Layer abun da ke ciki | Tsarin Epitaxial | Epitaxial matsakaici |

| Silicon homoepitaxial | Si | Si | Ramin Fashe Epitaxy (VPE) | SiCl4+H2 |

| Silicon heteroepitaxial | Sapphire ko kashin baya | Si | Ramin Fashe Epitaxy (VPE) | SiH₄+H₂ |

| GaAs Homoepitaxial | Ga | Ga Ga | Ramin Fashe Epitaxy (VPE) | AsCl₃+Ga+H₂ (Ar) |

| Ga | Ga Ga | Molecular Beam Epitaxy (MBE) | Ga+A | |

| GaAs heteroepitaxial | Ga Ga | GaAlAs/GaAs/GaAlAs | Halin Ruwa na Epitaxy (LPE) Yanayin tururi (VPE) | Ga+Al+Cas+ H2 Ga+AsH3+ PH3CHl+H2 |

| GaP Homoepitaxial | GaP | GaP (GaP; N) | Halin Ruwa na Epitaxy (LPE) Halin Ruwa na Epitaxy (LPE) | Ga+GaP+H2+ (NH3) Ga+GaAs+GaP+NH3 |

| Superlatice | Ga | GaAlAs/GaAs (cycle) | Molecular Beam Epitaxy (MBE) MOCVD | Ka, As, Al GaR₃+AlR3+AsH3+H2 |

| InP Homoepitaxial | InP | InP | Ramin Fashe Epitaxy (VPE) Halin Ruwa na Epitaxy (LPE) | PCl3+In+H2 In+InAs+GaAs+InP+H₂ |

| Si/GaAs Epitoxy | Si | Ga | Molecular Beam Epitaxy (MBE) MOGVD | Ga, as GaR₃+AsH₃+H₂ |

Lokacin aikawa: Dec-24-2024