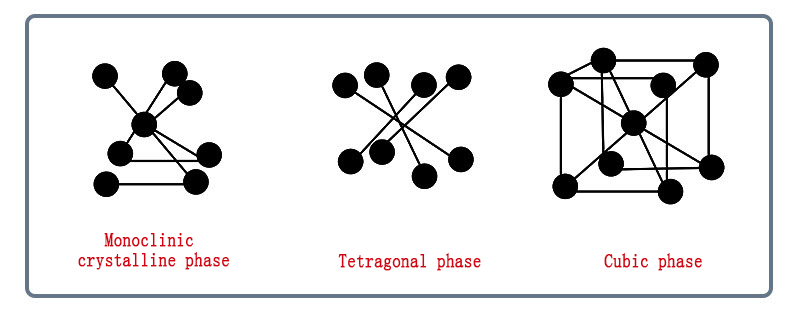

Zirconia yumburafari ne, rawaya ko launin toka lokacin da suke ɗauke da ƙazanta, kuma gabaɗaya sun ƙunshi HfO2, wanda ba shi da sauƙin rabuwa. Akwai jahohin crystal guda uku na tsarkakakken ZrO2 ƙarƙashin matsi na al'ada.

■Ƙananan zafin jiki na monoclinic (m-ZrO2)■Matsakaicin zafin jiki tetragonal (t-ZrO2)■Babban zafin jiki mai siffar sukari (c-ZrO2)

Waɗannan nau'ikan kristal guda uku da ke sama sun kasance a cikin kewayon zafin jiki daban-daban, kuma akwai alaƙar canjin juna masu zuwa:

Halayen yumbura na zirconia

High-narke-point

Zirconia narkewa batu ne: 2715 ℃, za a iya amfani da matsayin high zafin jiki refractory abu.

Babban taurin, juriya mai kyau

A cewar Mohs hardness: sapphire>Zirconia yumburaGilashin Corning> Aluminum magnesium alloy> Gilashin zafin jiki> polycarbonate

Babban ƙarfi da tauri

Ƙarfin zirconia zai iya kaiwa: 1500MPa

Low thermal conductivity da coefficient na fadada

Daga cikin kayan yumbu na yau da kullun, ƙarancin zafinsa shine mafi ƙanƙanta (1.6-2.03W/(mk)), kuma ƙimar haɓakar haɓakar thermal yana kusa da na ƙarfe.

Kyakkyawan aikin lantarki

Dielectric akai-akai na zirconia shine sau 3 na sapphire, kuma siginar ya fi dacewa.

Aikace-aikacen yumbura zirconia

Zirconia yumburaana amfani da su sosai a cikin kayan lantarki na 3C, sadarwa ta gani, sawa mai wayo, likitan ilimin halitta, kayan ado, rayuwar yau da kullun, kayan haɓakawa da sauran fannoni.

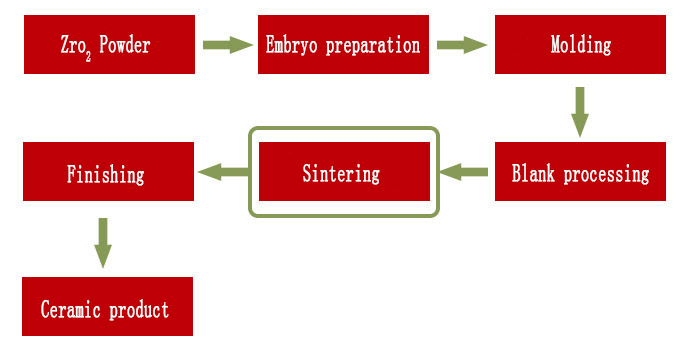

Fasahar shirye-shiryen yumbura na Zirconia

Sintering wani tsari ne mai mahimmanci a cikin shirye-shiryenzirconia yumbu, ingancin sintering zai shafi aikin yumbura kai tsaye, kawai yanayin zafin jiki ya daidaita daidai, jikin tayin zai zama cikakke. Sintering mara matsi shine mafi yawan amfani da hanyar sintering.

Saboda tsarki yumbu kayan wani lokacin wuya sintering, a karkashin yanayi na yi, wasu sintering Additives yawanci gabatar da su samar da wani m low narkewa batu na m bayani, gilashi lokaci ko wani ruwa lokaci, don inganta da sake shirya barbashi da danko ya kwarara. , don samun samfur mai yawa, amma kuma rage yawan zafin jiki.

Rage girman foda kamar yadda zai yiwu kuma yana ɗaya daga cikin mahimman matakan inganta sintering. Domin mafi kyawun foda, mafi girma da makamashi na saman, mafi sauƙi na sintering. Don kayan yumbura da samfuran tare da buƙatun aikin gama gari, ɓangarorin da ba matsi ba shine mafi dacewa da hanyar ɓata tattalin arziƙi.

Lokacin aikawa: Yuli-24-2023