Tundacrucibleana amfani da shi azaman akwati kuma akwai juzu'i a ciki, yayin da girman kristal da aka ƙirƙira yana ƙaruwa, yanayin zafi da daidaituwar yanayin zafin jiki ya zama mafi wahalar sarrafawa. Ta ƙara filin maganadisu don yin aikin narkar da keɓaɓɓiyar aiki akan ƙarfin Lorentz, za'a iya rage jinkirin convection ko ma kawar da shi don samar da siliki kristal guda ɗaya mai inganci.

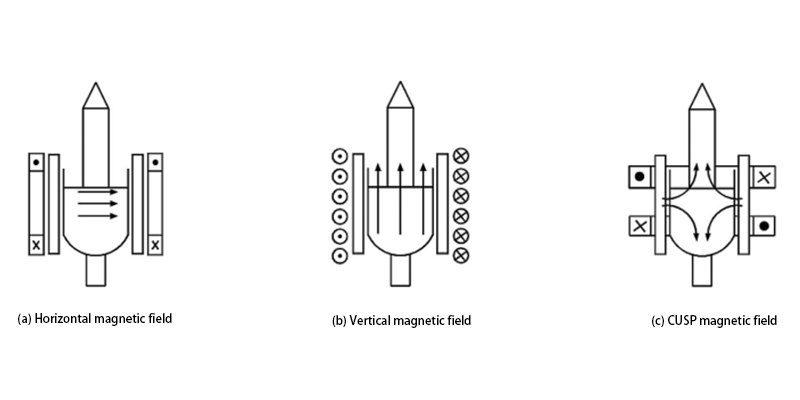

Dangane da nau'in filin maganadisu, ana iya raba shi zuwa filin maganadisu a kwance, filin maganadisu na tsaye da filin maganadisu na CUSP:

Filin maganadisu a tsaye ba zai iya kawar da babban haɗin gwiwa ba saboda dalilai na tsari kuma ba kasafai ake amfani da shi ba.

Jagorancin ɓangaren filin maganadisu na filin maganadisu na kwance yana tsaye zuwa babban yanayin zafi da kuma juzu'in tilastawa na bangon crucible, wanda zai iya hana motsi yadda yakamata, kula da fa'ida na ƙirar haɓaka, da rage ratsi girma.

Filin maganadisu na CUSP yana da ƙarin kwararar ɗabi'a da canjin zafi na narkewa saboda yanayin yanayinsa, don haka bincike kan filayen maganadisu na tsaye da CUSP yana tafiya hannu da hannu.

A kasar Sin, jami'ar fasaha ta Xi'an ta fahimci samarwa da gwaje-gwajen ja na siliki guda na lu'ulu'u ta amfani da filayen maganadisu a baya. Babban samfuransa sune nau'ikan shahararrun nau'ikan 6-8in, waɗanda ke da niyyar kasuwar wafer silicon don sel photovoltaic na hasken rana. A cikin ƙasashen waje, irin su KAYEX a Amurka da CGS a Jamus, manyan samfuran su sune 8-16in, waɗanda suka dace da sandunan siliki na crystal guda ɗaya a matakin manyan manyan sikelin haɗaɗɗun da'irori da semiconductor. Suna da keɓantacce a fagen filayen maganadisu don haɓaka manyan lu'ulu'u masu inganci masu girman girman diamita kuma sune mafi wakilci.

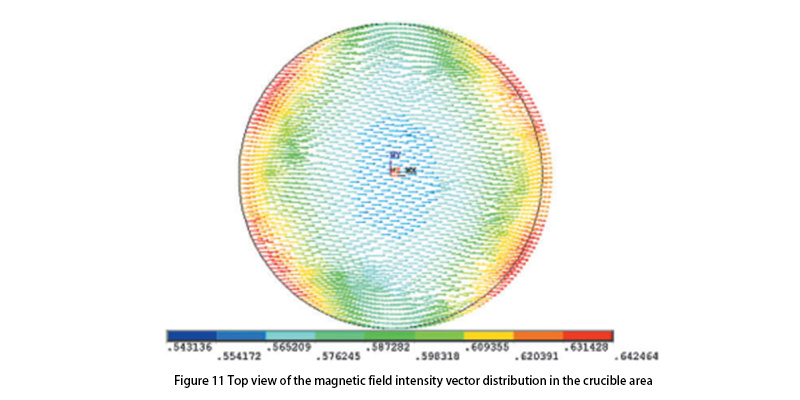

Rarraba filin maganadisu a cikin yanki mai ɓarna na tsarin haɓaka kristal guda ɗaya shine mafi mahimmancin ɓangaren maganadisu, gami da ƙarfi da daidaiton filin maganadisu a gefen crucible, tsakiyar crucible, da kuma dacewa. nisa a kasa da ruwa surface. Gabaɗayan filin maganadisu mai jujjuyawar kwance da uniform, layukan maganadisu na ƙarfi suna karkata zuwa ga axis girma na crystal. Dangane da tasirin maganadisu da ka'idar Ampere, coil ɗin yana kusa da gefen crucible kuma ƙarfin filin shine mafi girma. Yayin da nisa ya karu, juriya na iska yana ƙaruwa, ƙarfin filin yana raguwa a hankali, kuma shine mafi ƙanƙanta a tsakiya.

Matsayin babban filin maganadisu

Hana convection na thermal: Idan babu filin maganadisu na waje, narkar da siliki zai haifar da juzu'i na yanayi yayin dumama, wanda zai iya haifar da rarraba mara kyau na ƙazanta da samuwar lahani. Filin maganadisu na waje na iya murkushe wannan convection, yana sa rarrabawar zafin jiki a cikin narke ya zama iri ɗaya kuma yana rage rashin daidaituwar rarraba najasa.

Sarrafa ƙimar haɓakar kristal: Filin maganadisu na iya shafar ƙima da jagorar ci gaban crystal. Ta daidai sarrafa ƙarfi da rarraba filin maganadisu, ana iya inganta tsarin ci gaban kristal kuma ana iya inganta mutunci da daidaiton kristal. A lokacin haɓakar silikon kristal guda ɗaya, iskar oxygen yana shiga cikin siliki narke galibi ta hanyar motsin dangi na narkewa da crucible. Filin maganadisu yana rage damar iskar oxygen tuntuɓar siliki narke ta hanyar rage jujjuyawar narkewar, don haka rage rushewar iskar oxygen. A wasu lokuta, filin maganadisu na waje na iya canza yanayin yanayin zafi na narke, kamar ta hanyar canza yanayin tashin hankali na narke, wanda zai iya taimakawa haɓakar iskar oxygen, ta haka ne rage iskar oxygen a cikin narkewa.

Rage narkar da iskar oxygen da sauran ƙazanta: Oxygen ɗaya ne daga cikin ƙazanta na yau da kullun a cikin haɓakar lu'ulu'u na silicon, wanda zai haifar da ƙarancin kristal. Filin maganadisu na iya rage abubuwan da ke cikin iskar oxygen a cikin narkewar, ta yadda za a rage narkar da iskar oxygen a cikin kristal da inganta tsabtar kristal.

Inganta tsarin ciki na crystal: Filin maganadisu na iya shafar tsarin lahani a cikin kristal, kamar rarrabuwa da iyakokin hatsi. Ta hanyar rage adadin waɗannan lahani da kuma tasiri akan rarraba su, za'a iya inganta ingancin kristal gaba ɗaya.

Haɓaka kaddarorin lantarki na lu'ulu'u: Tun da filayen maganadisu suna da tasiri mai mahimmanci akan microstructure yayin haɓakar kristal, suna iya haɓaka kaddarorin lantarki na lu'ulu'u, kamar juriya da rayuwa mai ɗaukar nauyi, waɗanda ke da mahimmanci don kera manyan na'urorin semiconductor.

Maraba da kowane abokin ciniki daga ko'ina cikin duniya don ziyartar mu don ƙarin tattaunawa!

https://www.semi-cera.com/

https://www.semi-cera.com/tac-coating-monocrystal-growth-parts/

https://www.semi-cera.com/cvd-coating/

Lokacin aikawa: Yuli-24-2024