Quartz: Muhimmiyar Bangare a Kayan Lantarki na Zamani

Gabatarwa zuwa Material Quartz

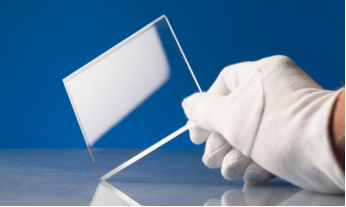

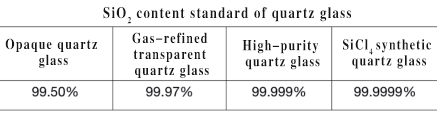

Quartz (SiO₂) na iya kama da gilashin a kallo na farko, amma keɓaɓɓen kaddarorin sa sun ware shi. Ba kamar daidaitaccen gilashin ba, wanda ya ƙunshi abubuwa da yawa (kamar yashi quartz, borax, barium carbonate, limestone, feldspar, da soda), quartz ya ƙunshi SiO₂ kaɗai. Wannan yana ba shi tsarin hanyar sadarwa mai sauƙi da aka kafa ta rukunin tetrahedral na silicon dioxide.

Muhimmancin Quartz Mai Tsabta

Ma'adini mai tsafta, wanda galibi ana kiransa "kambin kambi" na kayan gilashi, yana ba da kaddarori na musamman saboda ƙarancin ƙarancin ƙarfensa. Wannan abu mai ban mamaki yana da mahimmanci a cikin matakai daban-daban na semiconductor, yana alfahari da fa'idodi kamar:

1. Babban Juriya na Zazzabi: Tare da madaidaicin laushi na kusan 1730 ° C, ma'adini na iya jure wa amfani na dogon lokaci a 1150 ° C kuma yana ɗaukar gajeren fashe har zuwa 1450 ° C.

2. Chemical Resistance Resistance: High-tsarki ma'adini nuna kadan reactivity da mafi acid (sai hydrofluoric acid) da kuma nuna m kwanciyar hankali a kan sinadaran harin, kasancewa 30 sau fiye da acid-resistant fiye da yumbu da 150 sau fiye da resistant fiye da bakin karfe.

3. Ƙarfafawar thermal: Ma'adini mai tsafta yana da ƙarancin haɓaka haɓakar haɓakar thermal, yana ba shi damar jure saurin canjin zafin jiki ba tare da karyewa ba.

4. Tsabtace Na gani: Wannan abu yana kula da watsawa mai girma a fadin bakan, tare da watsawar haske mai gani wanda ya wuce 93% da watsawar ultraviolet ya kai sama da 80%.

5. Lantarki Insulation: High-tsarki ma'adini yayi na kwarai lantarki juriya, sa shi mai kyau insulator ko da a dagagge yanayin zafi.

Aikace-aikace a cikin Semiconductor Industry

Saboda waɗannan fitattun kaddarorin jiki da sinadarai, ana amfani da ma'adini mai tsafta sosai a cikin kayan lantarki na zamani, sadarwa, da masana'antar semiconductor. Haɓaka buƙatun wafers na silicon ya haɓaka buƙatun abubuwan ma'adini, musamman a masana'antar guntu.

Maɓallin Aikace-aikacen Quartz a Masana'antar Semiconductor:

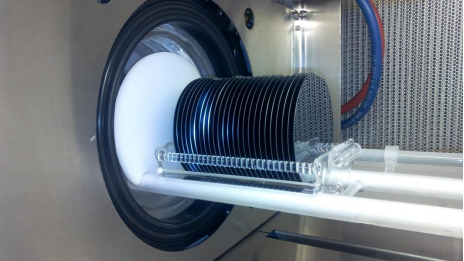

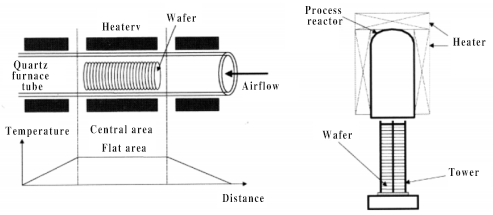

1. Na'urorin Zazzabi:

Tubes Furnace na Quartz:Mahimmanci don matakai kamar yadawa, oxidation, da annealing, waɗannan bututu suna tabbatar da kwanciyar hankali mai zafi da inganci yayin ƙirƙira semiconductor.

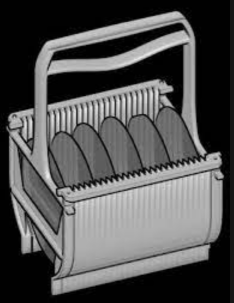

· Kwale-kwalen Quartz:An yi amfani da shi don jigilar kayayyaki da sarrafa wafern siliki, kwale-kwale na quartz suna sauƙaƙe masana'antar batch a cikin hanyoyin watsawa.

2. Na'urori masu ƙarancin zafin jiki:

Zoben Quartz:Haɗe-haɗe zuwa tsarin etching, zoben ma'adini suna hana gurɓatawa da tabbatar da ingantacciyar masana'anta yayin lithography da ƙirar ƙira.

Kwanduna Tsabtace Quartz da Tankuna:Waɗannan abubuwan haɗin gwiwa suna da mahimmanci don tsabtace wafern silicon. Dole ne su yi tsayayya da acid da alkali yayin da suke rage girman lamba don haɓaka aikin tsaftacewa.

Kammalawa

Yayin da abubuwan quartz na iya bayyana a matsayin ƙananan abubuwan da ake amfani da su a cikin tsarin masana'antar semiconductor, suna taka muhimmiyar rawa wajen tabbatar da inganci da amincin na'urorin semiconductor. A cewar Techcet, kayan gilashin ma'adini masu tsabta suna da kusan kashi 90% na abin da ake samarwa a duniya na shekara-shekara a masana'antar bayanai ta lantarki.

A Semicera, an sadaukar da mu don haɓaka masana'antar semiconductor ta hanyar samar da kayan ma'adini mai girma. Kamar yadda ƙusoshi ke da mahimmanci don amincin tsari, haka ma quartz don masana'antar semiconductor.

2. Na'urori masu ƙarancin zafin jiki:

·Ma'adini Rings: Haɗe-haɗe zuwa tsarin etching, zoben ma'adini suna hana gurɓatawa kuma tabbatar da ingantaccen masana'anta yayin lithography da ƙirar ƙira.

·Kwanduna Tsabtace Quartz da Tankuna: Waɗannan abubuwan haɗin suna da mahimmanci don tsabtace wafern siliki. Dole ne su yi tsayayya da acid da alkali yayin da suke rage girman lamba don haɓaka aikin tsaftacewa.

Kammalawa

Yayin da abubuwan quartz na iya bayyana a matsayin ƙananan abubuwan da ake amfani da su a cikin tsarin masana'antar semiconductor, suna taka muhimmiyar rawa wajen tabbatar da inganci da amincin na'urorin semiconductor. A cewar Techcet, kayan gilashin ma'adini masu tsabta suna da kusan kashi 90% na abin da ake samarwa a duniya na shekara-shekara a masana'antar bayanai ta lantarki.

A Semicera, an sadaukar da mu don haɓaka masana'antar semiconductor ta hanyar samar da kayan ma'adini mai girma. Kamar yadda ƙusoshi ke da mahimmanci don amincin tsari, haka ma quartz don masana'antar semiconductor.