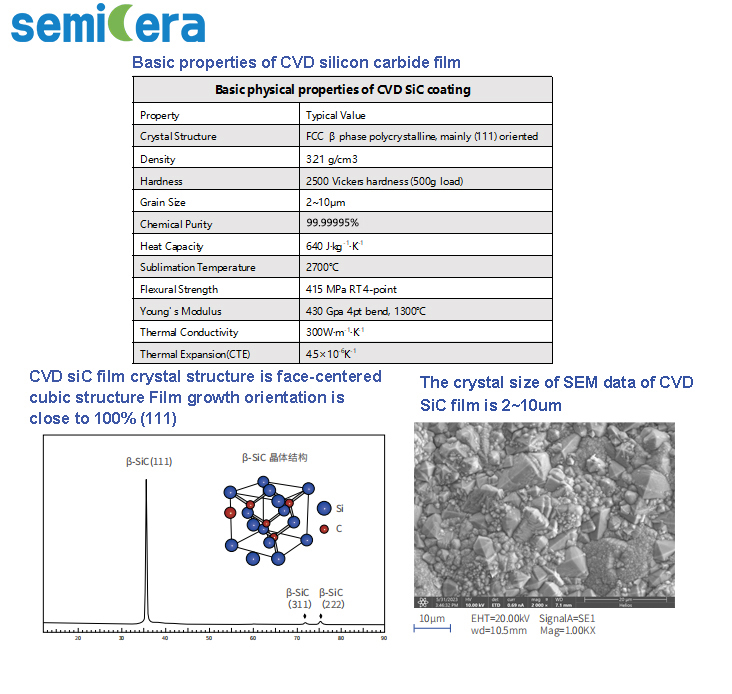

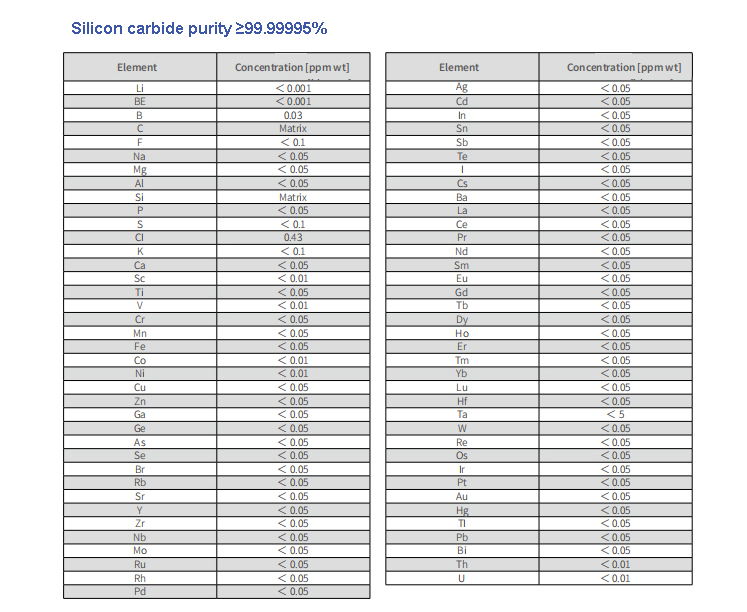

A cikin filin semiconductor, kwanciyar hankali na kowane bangare yana da mahimmanci ga dukan tsari. Duk da haka, a cikin yanayin zafi mai zafi, graphite yana da sauƙi oxidized kuma ya ɓace, kuma SiC shafi na iya ba da kariya ga barga don sassan graphite. A cikinSemiceratawagar, muna da namu graphite tsarkakewa kayan aiki, wanda zai iya sarrafa da tsarki na graphite kasa 5ppm. Tsaftar murfin siliki carbide yana ƙasa da 0.5 ppm.

✓Mafi inganci a kasuwar kasar Sin

✓ Kyakkyawan sabis koyaushe a gare ku, 7*24 hours

✓ Gajeren kwanan watan bayarwa

✓ Ƙananan MOQ maraba da karɓa

✓ Sabis na musamman

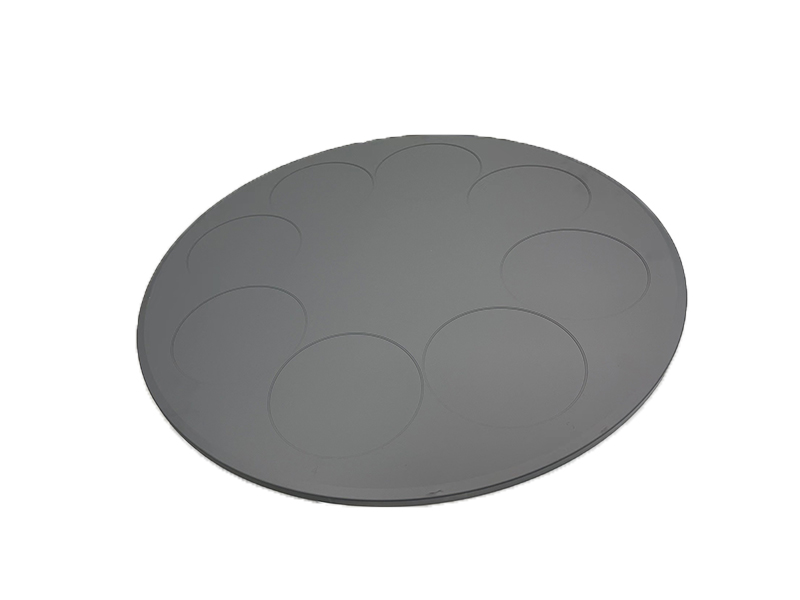

Epitaxy Growth Susceptor

Silicon/silicon carbide wafers suna buƙatar tafiya ta matakai da yawa don amfani da na'urorin lantarki. Wani muhimmin tsari shine silicon/sic epitaxy, wanda ake ɗaukar siliki / sic wafers akan tushe mai hoto. Fa'idodi na musamman na tushe mai rufaffen siliki na Silicon carbide na Semicera sun haɗa da tsafta mai girman gaske, sutura iri ɗaya, da tsawon rayuwar sabis. Hakanan suna da juriya na sinadarai da kwanciyar hankali.

LED Chip Production

A lokacin faffadan lulluɓe na reactor na MOCVD, tushen duniya ko mai ɗaukar kaya yana motsa wafern. Ayyukan kayan aiki na tushe yana da tasiri mai girma akan ingancin sutura, wanda hakan yana rinjayar ƙimar guntu. Tushen mai rufaffiyar siliki na Semicera yana ƙara ingantaccen masana'anta na wafers masu inganci na LED kuma yana rage karkatar da tsayin raƙuman ruwa. Hakanan muna ba da ƙarin abubuwan haɗin graphite don duk injinan MOCVD da ake amfani da su a halin yanzu. Za mu iya yin sutura kusan kowane abu tare da murfin siliki na carbide, ko da diamita na bangaren ya kai 1.5M, har yanzu muna iya sutura da siliki carbide.

Filin Semiconductor, Tsarin Yadawa Oxidation, Da dai sauransu.

A cikin semiconductor tsari, da hadawan abu da iskar shaka tsarin fadadawa bukatar high samfurin tsarki, kuma a Semicera muna bayar da al'ada da CVD shafi sabis ga mafi yawan silicon carbide sassa.

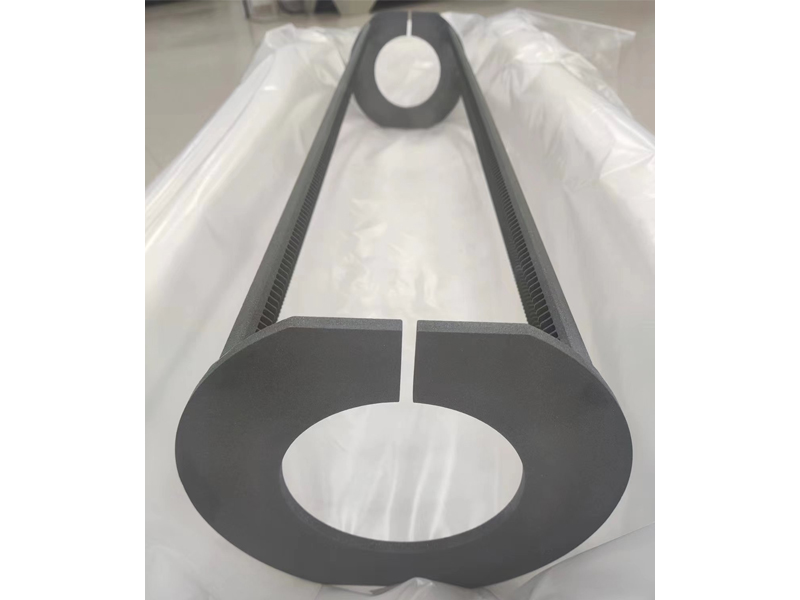

Hoton da ke gaba yana nuna slurry silicon carbide slurry na Semicea da kuma bututun murhun wuta na silicon carbide wanda aka tsaftace a cikin 1000-matakimara ƙuradakin. Ma'aikatanmu suna aiki kafin rufewa. Tsaftar siliki carbide ɗin mu na iya kaiwa 99.99%, kuma tsabtar sic ɗin ta fi 99.99995%.

Raw Silicon Carbide Paddle da SiC Process Tube a cikin Tsabtace

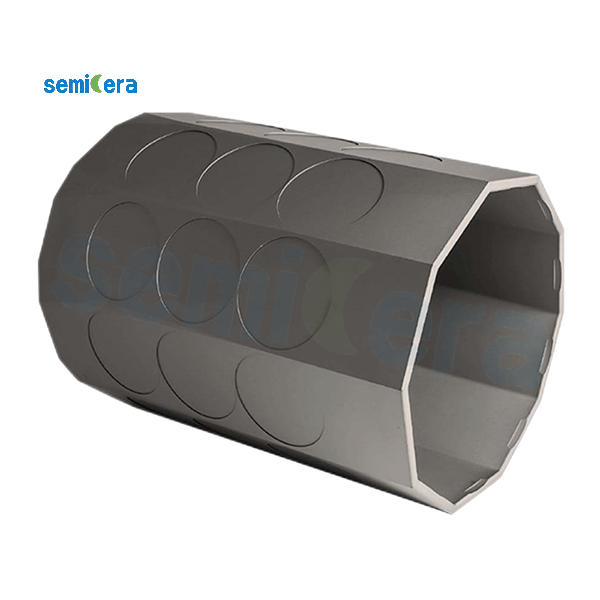

Silicon Carbide Wafer Boat CVD SiC mai rufi