A halin yanzu, ƙarni na uku na semiconductors ya mamayesiliki carbide. A cikin tsarin farashi na na'urorin sa, ƙirar tana da 47%, kuma epitaxy tana da 23%. Dukansu biyu tare suna lissafin kusan 70%, wanda shine mafi mahimmancin ɓangarensiliki carbidesarkar masana'antar kera na'ura.

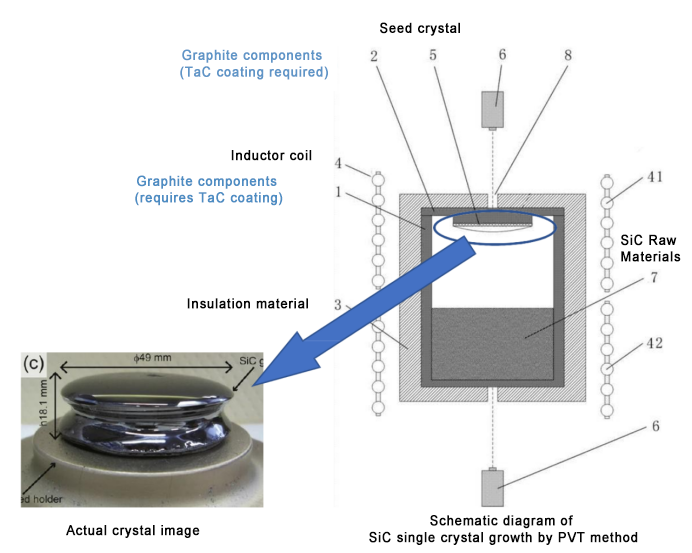

Hanyar da aka saba amfani da ita don shiryawasiliki carbidelu'ulu'u guda ɗaya shine hanyar PVT (hanyar tururi ta jiki). Ka'idar ita ce yin albarkatun ƙasa a cikin babban yankin zafin jiki da kuma kristal iri a cikin wani yanki mai ƙarancin zafi. Kayan albarkatun kasa a cikin zafin jiki mafi girma suna bazuwa kuma suna samar da abubuwan lokaci na gas kai tsaye ba tare da lokacin ruwa ba. Wadannan abubuwan lokaci na iskar gas ana jigilar su zuwa kristal iri a ƙarƙashin tuƙi na gradient zafin jiki na axial, kuma suna haɓaka kuma suna girma a kristal iri don samar da crystal carbide guda ɗaya. A halin yanzu, kamfanonin kasashen waje irin su Cree, II-VI, SiCrystal, Dow da na cikin gida irin su Tianyue Advanced, Tianke Heda, da Century Golden Core duk suna amfani da wannan hanya.

Akwai fiye da nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'in kristal 4H). A cewar Tianyue Advanced's prospectus, samar da crystal na kamfanin a cikin 2018-2020 da H1 2021 sun kasance 41%, 38.57%, 50.73% da 49.90% bi da bi, da substrate da ake samu sun kasance 72.61%, 75.15% bi da bi, 75.15%. Babban yawan amfanin ƙasa a halin yanzu shine kawai 37.7%. Ɗaukar babbar hanyar PVT a matsayin misali, ƙarancin yawan amfanin ƙasa ya samo asali ne saboda matsaloli masu zuwa a cikin shirye-shiryen substrate na SiC:

1. Wahala a zazzabi filin kula da: SiC crystal sanduna bukatar da za a samar a wani babban zafin jiki na 2500 ℃, yayin da silicon lu'ulu'u ne kawai bukatar 1500 ℃, don haka musamman guda crystal tanderu ake bukata, da kuma girma zafin jiki bukatar da za a daidai sarrafawa a lokacin samar. , wanda ke da matukar wuyar sarrafawa.

2. Slow samar gudun: The girma kudi na gargajiya silicon kayan ne 300 mm a kowace awa, amma silicon carbide guda lu'ulu'u iya kawai girma 400 microns a kowace awa, wanda shi ne kusan 800 sau bambanci.

3. Babban buƙatun don sigogin samfur mai kyau, da yawan amfanin ƙasa na akwatin baƙar fata yana da wahala a sarrafa lokaci: Mahimman sigogi na wafers na SiC sun haɗa da ƙarancin microtube, ƙarancin dislocation, tsayayya, warpage, rashin ƙarfi na ƙasa, da dai sauransu A lokacin tsarin girma na crystal, shine ya zama dole don sarrafa daidaitattun sigogi kamar rabon silicon-carbon, gradient zafin girma, ƙimar girma na crystal, da matsa lamba na iska. In ba haka ba, yuwuwar shigar da polymorphic zai iya faruwa, yana haifar da lu'ulu'u marasa cancanta. A cikin akwatin baƙar fata na graphite crucible, ba shi yiwuwa a lura da matsayin ci gaban kristal a ainihin lokacin, kuma ana buƙatar madaidaicin kula da filin zafi, daidaita kayan, da tara gwaninta.

4. Wahala a cikin haɓakar kristal: A ƙarƙashin tsarin jigilar iskar gas, fasahar haɓakar ci gaban kristal SiC yana da matukar wahala. Yayin da girman lu'ulu'u ya karu, wahalar haɓakarsa yana ƙaruwa sosai.

5. Gabaɗaya ƙananan yawan amfanin ƙasa: Ƙananan yawan amfanin ƙasa yana kunshe da hanyoyi guda biyu: (1) Ƙimar sandar Crystal = semiconductor-grade crystal sanda fitarwa / (semiconductor-grade crystal sanda fitarwa + non-semiconductor-sa crystal sanda fitarwa) × 100%; (2) Yawan amfanin ƙasa = ƙwararrun kayan aiki / (ƙwararrun kayan aikin da ba a iya amfani da su ba) × 100%.

A cikin shirye-shiryen babban inganci da yawan amfanin ƙasasilicon carbide substrates, ainihin yana buƙatar mafi kyawun kayan filin thermal don sarrafa daidaitattun zafin jiki na samarwa. Kayan aikin filin thermal crucible a halin yanzu ana amfani da su galibi manyan sassa na tsari ne na graphite, waɗanda ake amfani da su don zafi da narke foda na carbon da foda na silicon da dumi. Kayan graphite suna da halaye na ƙayyadaddun ƙarfi da ƙayyadaddun modules, kyakkyawan juriya na girgiza zafin zafi da juriya na lalata, amma suna da rashin lahani na kasancewa cikin sauƙi oxidized a cikin yanayin yanayin iskar oxygen mai zafi, ba juriya ga ammonia, da juriya mara kyau. A kan aiwatar da silicon carbide guda crystal girma da kumasiliki carbide epitaxial wafersamarwa, yana da wahala a cika buƙatun mutane masu ƙarfi don amfani da kayan aikin graphite, wanda ke hana haɓakawa da aikace-aikacen aikace-aikace sosai. Sabili da haka, suturar zafi mai zafi irin su tantalum carbide sun fara fitowa.

2. HalayenTantalum Carbide Coating

TaC yumbu yana da wurin narkewa na har zuwa 3880 ℃, babban taurin (Mohs hardness 9-10), babban haɓakar thermal (22W · m-1 · K-1), babban ƙarfin lanƙwasa (340-400MPa), da ƙaramin haɓakar thermal coefficient (6.6 × 10-6K-1), kuma yana nuna kyakkyawan kwanciyar hankali na thermochemical da kyawawan kaddarorin jiki. Yana da kyakyawan daidaituwar sinadarai da daidaiton injina tare da graphite da kayan haɗin C/C. Sabili da haka, ana amfani da suturar TaC sosai a cikin kariya ta thermal na sararin samaniya, haɓaka kristal guda ɗaya, na'urorin lantarki, da kayan aikin likita.

TaC mai rufigraphite yana da mafi kyawun juriya na lalata sinadarai fiye da graphite mara kyau ko graphite mai rufin SiC, ana iya amfani da shi a tsaye a yanayin zafi na 2600°, kuma baya amsa da abubuwa da yawa na ƙarfe. Shine mafi kyawun shafi a cikin ƙarni na uku na semiconductor ci gaban kristal guda ɗaya da yanayin etching na wafer. Zai iya inganta mahimmancin kula da zafin jiki da ƙazanta a cikin tsari da shiryahigh quality silicon carbide wafersda alakaepitaxial wafers. Ya dace musamman don girma GaN ko AlN lu'ulu'u guda ɗaya tare da kayan aikin MOCVD da haɓaka lu'ulu'u na SiC guda ɗaya tare da kayan aikin PVT, kuma ingancin lu'ulu'u masu girma da yawa sun inganta sosai.

III. Fa'idodin Tantalum Carbide Rufaffen Na'urorin

Yin amfani da murfin Tantalum Carbide TaC zai iya magance matsalar lahani na kristal da inganta ingancin ci gaban crystal. Yana ɗaya daga cikin mahimman kwatance fasaha na "girma da sauri, girma mai kauri, da girma mai tsawo". Har ila yau, binciken masana'antu ya nuna cewa Tantalum Carbide mai rufi Graphite Crucible zai iya samun ƙarin dumama iri ɗaya, ta haka yana samar da kyakkyawan tsarin sarrafawa don ci gaban SiC guda ɗaya, don haka rage yiwuwar samuwar polycrystalline a gefen SiC lu'ulu'u. Bugu da ƙari, Tantalum Carbide Graphite Coating yana da manyan fa'idodi guda biyu:

(I) Rage Lalacewar SiC

Dangane da sarrafa lahani na SiC guda ɗaya, yawanci akwai hanyoyi masu mahimmanci guda uku. Bugu da ƙari, inganta sigogi na girma da kayan aiki masu inganci (irin su SiC tushen foda), ta yin amfani da Tantalum Carbide Coated Graphite Crucible kuma zai iya cimma kyakkyawan ingancin crystal.

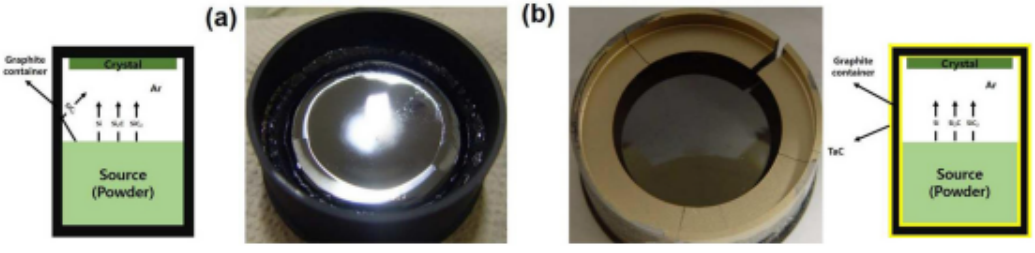

Zane-zane na al'ada graphite crucible (a) da TAC mai rufi crucible (b)

Dangane da binciken da Jami'ar Gabashin Turai a Koriya ta yi, babban ƙazanta a cikin ci gaban kristal na SiC shine nitrogen, kuma tantalum carbide mai rufin graphite crucibles na iya iyakance haɗakar nitrogen da lu'ulu'u na SiC yadda ya kamata, don haka rage haɓakar lahani kamar micropipes da haɓaka crystal. inganci. Nazarin ya nuna cewa a ƙarƙashin yanayi iri ɗaya, ƙididdigar masu ɗaukar nauyin SiC wafers da aka girma a cikin ginshiƙan ginshiƙan graphite na al'ada da TAC mai rufin crucibles kusan 4.5 × 1017 / cm da 7.6 × 1015 / cm, bi da bi.

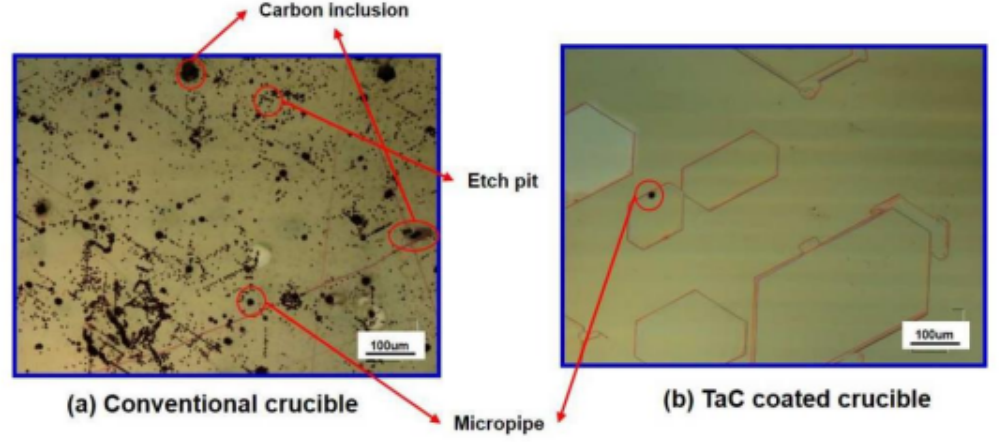

Kwatanta lahani a cikin SiC lu'ulu'u guda ɗaya waɗanda aka girma a cikin ginshiƙan graphite na al'ada (a) da TAC masu rufi (b)

(II) Inganta rayuwar graphite crucibles

A halin yanzu, farashin lu'ulu'u na SiC ya kasance mai girma, wanda farashin kayan masarufi na graphite ya kai kusan 30%. Makullin rage farashin kayan masarufi na graphite shine haɓaka rayuwar sabis. Dangane da bayanai daga ƙungiyar bincike ta Burtaniya, suturar tantalum carbide na iya tsawaita rayuwar sabis na abubuwan graphite da kashi 30-50%. Bisa ga wannan lissafin, kawai maye gurbin tantalum carbide mai rufi graphite zai iya rage farashin SiC crystals da 9% -15%.

4. Tantalum carbide shafi shiri tsari

TaC shafi shirye-shirye hanyoyin za a iya raba uku Categories: m lokaci hanya, ruwa lokaci hanya da gas lokaci hanya. Tsarin lokaci mai ƙarfi ya ƙunshi hanyar ragewa da hanyar sinadarai; Hanyar lokaci na ruwa ya haɗa da hanyar gishiri narke, hanyar sol-gel (Sol-Gel), hanyar slurry-sintering, hanyar fesa plasma; Hanyar lokaci na iskar gas ya haɗa da ƙaddamar da tururi na sinadarai (CVD), shigar da tururi na sinadarai (CVI) da kuma shigar da tururi ta jiki (PVD). Hanyoyi daban-daban suna da nasu amfani da rashin amfani. Daga cikin su, CVD wata hanya ce ta balagagge kuma ana amfani da ita sosai don shirya suturar TaC. Tare da ci gaba da inganta tsarin, an haɓaka sabbin matakai kamar surar sinadari mai zafi na waya mai zafi da ion katako da ke taimaka wa jijiya sinadarai.

Abubuwan da aka gyara na TaC sun haɗa da graphite, fiber carbon, da kayan haɗin carbon/carbon. Hanyoyin shirya suturar TaC akan graphite sun haɗa da fesa plasma, CVD, slurry sintering, da sauransu.

Amfanin hanyar CVD: Hanyar CVD don shirya suturar TaC ta dogara ne akan tantalum halide (TaX5) azaman tushen tantalum da hydrocarbon (CnHm) azaman tushen carbon. A ƙarƙashin wasu sharuɗɗa, ana lalata su cikin Ta da C, sannan su amsa tare da juna don samun suturar TaC. Ana iya aiwatar da hanyar CVD a ƙananan zafin jiki, wanda zai iya guje wa lahani da rage yawan kayan aikin injiniya wanda ya haifar da shirye-shiryen zafin jiki mai zafi ko kuma kula da sutura zuwa wani matsayi. Abun da ke ciki da tsarin rufin ana iya sarrafawa, kuma yana da fa'idodi na babban tsabta, babban yawa, da kauri iri ɗaya. Mafi mahimmanci, abun da ke ciki da tsarin suturar TaC da aka shirya ta CVD za a iya tsarawa da sauƙin sarrafawa. Hanya ce ta balagagge kuma ana amfani da ita sosai don shirya kayan kwalliyar TaC masu inganci.

Babban abubuwan da ke da tasiri na tsarin sun haɗa da:

A. Gas kwarara kudi (tantalum tushen, hydrocarbon gas a matsayin carbon source, m gas, dilution gas Ar2, rage gas H2): Canjin gas kwarara kudi yana da babban tasiri a kan yanayin zafi filin, matsa lamba filin, da kuma iskar gas filin a ɗakin amsawa, yana haifar da canje-canje a cikin abun da ke ciki, tsari, da aikin sutura. Ƙara yawan ƙimar Ar zai rage saurin haɓakar haɓakar shafi kuma ya rage girman hatsi, yayin da ma'auni na molar taro na TaCl5, H2, da C3H6 yana rinjayar abun da ke ciki. Matsakaicin molar H2 zuwa TaCl5 shine (15-20): 1, wanda ya fi dacewa. Matsakaicin molar na TaCl5 zuwa C3H6 yana kusa da 3:1. Yawan TaCl5 ko C3H6 zai haifar da samuwar Ta2C ko carbon kyauta, yana shafar ingancin wafer.

B. Yawan zafin jiki: Mafi girma yawan zafin jiki, da sauri yawan adadin kuɗi, mafi girma girman hatsi, kuma mafi girman murfin. Bugu da kari, yanayin zafi da saurin rubewar hydrocarbon zuwa C da TaCl5 rugujewar TaCl5 zuwa Ta sun bambanta, kuma Ta da C sun fi zama Ta2C. Zazzabi yana da babban tasiri akan kayan aikin carbon da aka gyara na TaC. Yayin da yawan zafin jiki ya ƙaru, ƙimar ajiya yana ƙaruwa, girman barbashi yana ƙaruwa, kuma sifar barbashi yana canzawa daga mai siffar zobe zuwa polyhedral. Bugu da ƙari, mafi girma yawan zafin jiki na ajiya, da sauri da rushewar TaCl5, ƙananan C zai zama, mafi girma da damuwa a cikin sutura, kuma za a iya haifar da raguwa cikin sauƙi. Duk da haka, ƙananan zafin jiki na ajiya zai haifar da raguwar tasirin ajiya, daɗaɗɗen lokacin ajiya, da ƙarin farashin albarkatun ƙasa.

C. Deposition matsa lamba: Deposition matsa lamba ne a kusa da alaka da free makamashi na kayan surface da zai shafi gas mazaunin lokaci a cikin dauki dakin, game da shi rinjayar da nucleation gudun da barbashi size na shafi. Yayin da matsin lamba ya karu, lokacin zama na gas ya zama tsayi, masu amsawa suna da ƙarin lokaci don shawo kan halayen nucleation, ƙimar amsawa yana ƙaruwa, barbashi ya zama ya fi girma, kuma murfin ya zama mai kauri; Sabanin haka, yayin da matsin lamba ya ragu, lokacin zama na iskar gas yana ɗan gajeren lokaci, ƙimar amsawa ta ragu, ɓarna ta zama ƙarami, kuma murfin ya fi ƙanƙanta, amma matsin lamba yana da ɗan tasiri akan tsarin crystal da abun da ke ciki na shafi.

V. Ci gaban yanayin tantalum carbide shafi

Matsakaicin haɓakar haɓakar thermal na TaC (6.6 × 10-6K-1) ya ɗan bambanta da na kayan da ake amfani da su na carbon kamar graphite, fiber carbon, da kayan haɗin gwiwar C / C, wanda ke sanya suturar TaC guda ɗaya mai saurin fashewa fadowa. Domin ya kara inganta ablation da hadawan abu da iskar shaka juriya, high-zazzabi inji kwanciyar hankali, da kuma high-zazzabi sinadaran lalata juriya na TaC coatings, masu bincike sun gudanar da bincike a kan shafi tsarin kamar hadawa shafi tsarin, m bayani-inganta shafi tsarin, da kuma gradient. tsarin sutura.

Tsarin suturar haɗakarwa shine don rufe ɓarna na sutura ɗaya. Yawancin lokaci, ana gabatar da wasu sutura a cikin farfajiya ko ciki na TaC don samar da tsarin suturar kayan aiki; da m bayani ƙarfafa shafi tsarin HfC, ZrC, da dai sauransu da wannan fuska-tsakiyar cubic tsarin kamar yadda TaC, da biyu carbides iya zama mara iyaka mai narkewa a cikin juna don samar da wani m bayani tsarin. Rufin Hf (Ta) C ba shi da fasa kuma yana da kyau adhesion zuwa kayan haɗin C/C. Rufin yana da kyakkyawan aikin anti-ablation; da gradient shafi tsarin gradient shafi yana nufin shafi bangaren maida hankali tare da kauri shugabanci. Tsarin zai iya rage damuwa na ciki, inganta rashin daidaituwa na haɓakar haɓakawar thermal, da kuma guje wa fasa.

(II) Tantalum carbide kayan shafa na'urar

Dangane da kididdigar da kididdiga na QYR (Hengzhou Bozhi), tallace-tallacen kasuwar tantalum carbide na duniya a cikin 2021 ya kai dalar Amurka miliyan 1.5986 (ban da samfuran na'urar tantalum carbide ta Cree da ta samar da kanta), kuma har yanzu tana cikin farkon farawa. matakan ci gaban masana'antu.

1. Crystal fadada zobba da crucibles da ake bukata domin crystal girma: Dangane da 200 crystal girma tanderu da sha'anin, da kasuwar rabo na TaC rufi na'urorin da ake bukata da 30 crystal girma kamfanoni ne game da 4.7 biliyan yuan.

2. TaC: Kowanne tire na iya daukar waina 3, kowacce tire za a iya amfani da ita tsawon wata 1, sannan a rika shan tire 1 a kowace wafer 100. Wafers miliyan 3 na buƙatar tireshin TaC 30,000, kowane tire kusan guda 20,000 ne, kuma ana buƙatar kusan miliyan 600 kowace shekara.

3. Sauran yanayin rage yawan carbon. Irin su rufin tanderu mai zafi mai zafi, bututun CVD, bututun tanderu, da sauransu, kusan miliyan 100.

Lokacin aikawa: Jul-02-2024