2. Tsarin Gwaji

2.1 Maganin Fim ɗin Adhesive

An lura cewa kai tsaye ƙirƙirar fim ɗin carbon ko haɗin kai tare da takarda graphite akanSiC wafersRufe tare da m ya haifar da batutuwa da yawa:

1. A ƙarƙashin yanayin yanayi, fim ɗin mSiC wafersɓullo da sikelin sikelin saboda gagarumin sakin iska, wanda ya haifar da porosity na saman. Wannan ya hana manne yadudduka daga yadda ya kamata bond bayan carbonization.

2. A lokacin bonding, dawaferdole ne a sanya shi a kan takardar graphite a tafi ɗaya. Idan sakewa ya faru, matsa lamba mara daidaituwa na iya rage daidaituwar mannewa, yana haifar da mummunan tasirin haɗin gwiwa.

3. A cikin ayyukan motsa jiki, sakin iska daga maɗauran mannewa ya haifar da peeling da samuwar ɓoyayyen ɓoyayyiya a cikin fim ɗin m, yana haifar da lahani na haɗin gwiwa. Don magance waɗannan batutuwa, riga-kafin busar da manne akanwafer taAna ba da shawarar haɗin kai ta amfani da farantin zafi bayan an yi amfani da sutura.

2.2 Tsarin Carbonization

Tsarin ƙirƙirar fim ɗin carbon akanSiC iri waferkuma haɗa shi da takarda mai graphite yana buƙatar carbonization na manne Layer a takamaiman zafin jiki don tabbatar da haɗin gwiwa mai ƙarfi. Rashin cikar carbonization na manne Layer na iya haifar da rugujewar sa yayin girma, sakin ƙazanta waɗanda ke shafar ingancin ci gaban crystal. Saboda haka, tabbatar da cikakken carbonization na manne Layer yana da mahimmanci don haɗuwa mai yawa. Wannan binciken yana nazarin tasirin zafin jiki akan carbonization m. An yi amfani da wani nau'in nau'in hoto na hotowafersaman kuma sanya shi a cikin tanderun bututu a ƙarƙashin injin (<10 Pa). An ɗaga zafin jiki zuwa matakan da aka saita (400 ℃, 500 ℃, da 600 ℃) kuma ana kiyaye shi don 3-5 hours don cimma carbonization.

Gwaje-gwajen sun nuna:

A 400 ℃, bayan 3 hours, m film bai carbonize da kuma bayyana duhu ja; ba a sami wani gagarumin canji ba bayan sa'o'i 4.

A 500 ℃, bayan 3 hours, fim din ya zama baki amma har yanzu yana watsa haske; babu wani gagarumin canji bayan 4 hours.

A 600 ℃, bayan sa'o'i 3, fim din ya juya baki ba tare da watsa haske ba, yana nuna cikakken carbonization.

Saboda haka, da dace bonding zafin jiki bukatar ya zama ≥600 ℃.

2.3 Tsarin aikace-aikacen m

Daidaitawar fim ɗin mannewa alama ce mai mahimmanci don kimanta tsarin aikace-aikacen manne da tabbatar da haɗin haɗin kai. Wannan sashe yana bincika mafi kyawun saurin juzu'i da lokacin rufewa don nau'ikan kaurin fim daban-daban. Daidaituwa

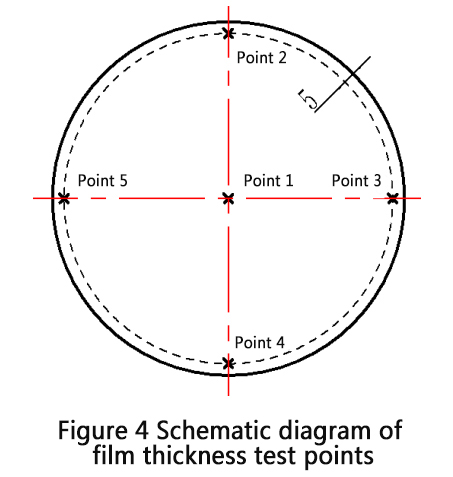

An ayyana kaurin fim ɗin azaman ƙimar mafi ƙarancin kauri na fim Lmin zuwa matsakaicin kauri na fim Lmax akan yanki mai amfani. An zaɓi maki biyar akan wafer don auna girman fim ɗin, kuma an ƙididdige daidaito. Hoto na 4 yana kwatanta ma'aunin ma'auni.

Don haɗin kai mai girma tsakanin wafern SiC da abubuwan graphite, kaurin fim ɗin manne da aka fi so shine 1-5 µm. An zaɓi kauri na fim na 2 µm, wanda ya dace da shirye-shiryen fim ɗin carbon da tsarin haɗin takarda na wafer/graphite. Mafi kyawun ma'aunin suturar sutura don mannen carbonizing shine 15 s a 2500 r/min, kuma don haɗin haɗin gwiwa, 15 s a 2000 r/min.

2.4 Tsari Tsari

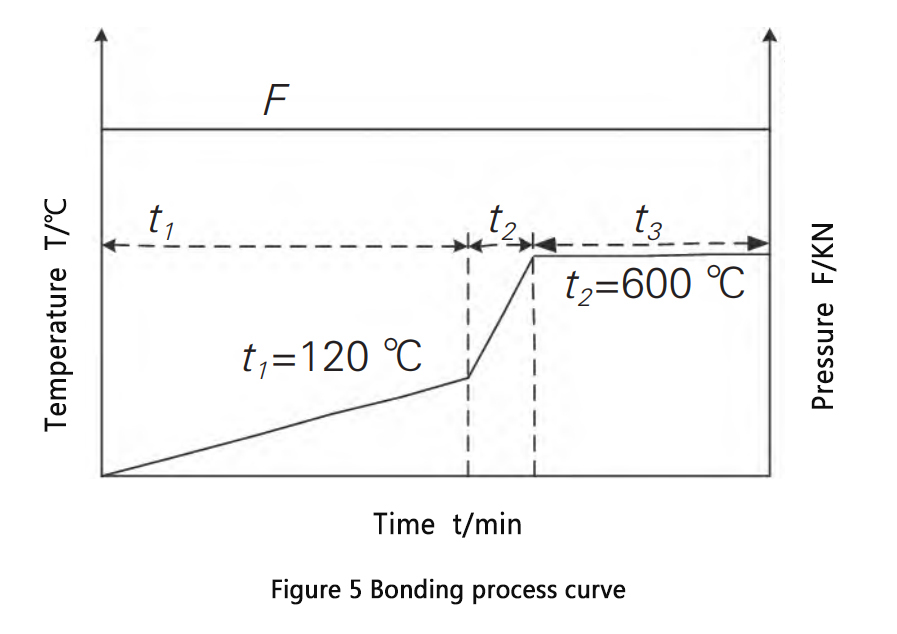

A lokacin haɗin SiC wafer zuwa takarda mai hoto / graphite, yana da mahimmanci don kawar da iska gaba ɗaya da iskar gas da aka haifar yayin carbonization daga Layer bonding. Rashin cikar kawar da iskar gas yana haifar da ɓoyayyiya, wanda ke haifar da ɓangarorin haɗin gwiwa mara ƙarfi. Ana iya fitar da iska da iskar gas ta amfani da famfon mai na inji. Da farko, ci gaba da aiki na famfo na inji yana tabbatar da ɗakin ɗakin ya kai iyakarsa, yana ba da damar cire cikakkiyar iska daga layin haɗin gwiwa. Hawan zafin jiki mai sauri zai iya hana kawar da iskar gas akan lokaci yayin babban zafin jiki na carbonization, haifar da ɓoyayyiya a cikin layin haɗin gwiwa. Abubuwan mannewa suna nuna iskar gas mai mahimmanci a ≤120 ℃, yana daidaita sama da wannan zafin jiki.

Ana amfani da matsa lamba na waje yayin haɗin gwiwa don haɓaka girman fim ɗin mannewa, yana sauƙaƙe fitar da iska da iskar gas, yana haifar da babban haɗin haɗin gwiwa.

A taƙaice, an ɓullo da tsarin tsarin haɗin kai da aka nuna a hoto na 5. Ƙarƙashin ƙayyadaddun matsa lamba, ana ɗaga zafin jiki zuwa zafin jiki mai fita (~ 120 ℃) kuma ana riƙe har sai an gama fitar da gas. Sa'an nan, ana ƙara yawan zafin jiki zuwa zafin jiki na carbonization, ana kiyaye shi don tsawon lokacin da ake buƙata, sa'an nan kuma sanyaya yanayi zuwa zafin jiki, sakin matsa lamba, da kuma cire wafer da aka haɗa.

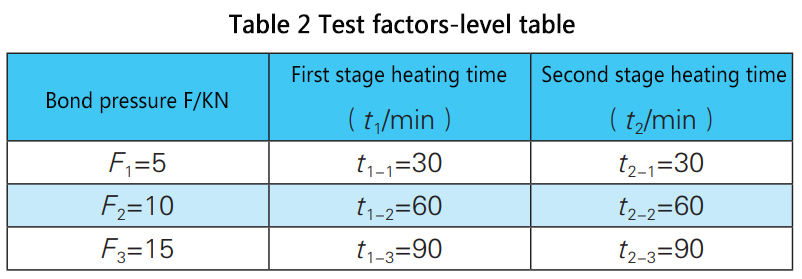

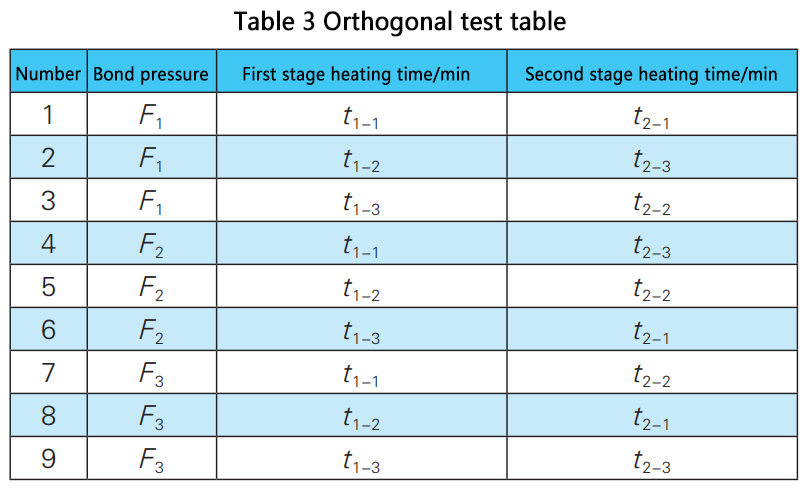

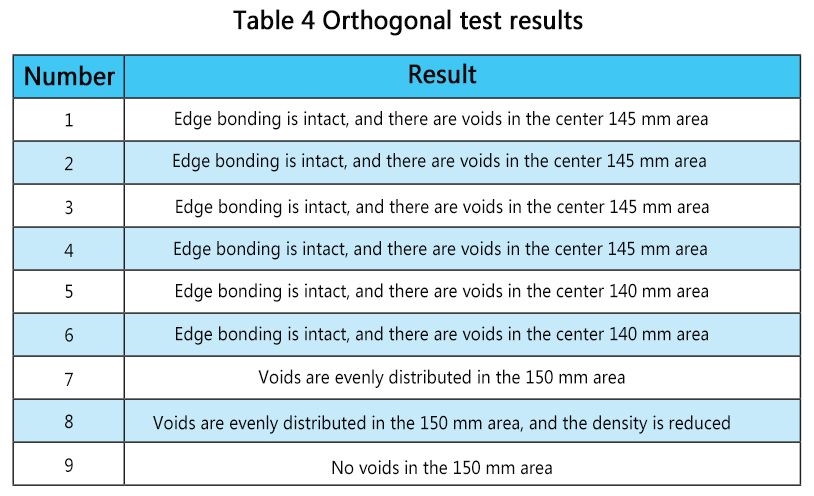

Dangane da sashe na 2.2, fim ɗin m yana buƙatar zama carbonized a 600 ℃ sama da 3 hours. Saboda haka, a cikin bonding tsari kwana, T2 an saita zuwa 600 ℃ da t2 zuwa 3 hours. Mafi kyawun dabi'u don tsarin tsarin haɗin gwiwa, ƙaddara ta hanyar gwaje-gwajen orthogonal da ke nazarin tasirin matsa lamba, lokacin zafi na farko t1, da lokacin zafi na biyu t2 akan sakamakon haɗin gwiwa, an nuna su a cikin Tables 2-4.

Sakamakon ya nuna:

A matsin lamba na 5 kN, lokacin dumama yana da ɗan tasiri akan haɗin gwiwa.

A 10 kN, wurin mara komai a cikin layin haɗin gwiwa ya ragu tare da dogon dumama matakin farko.

A 15 kN, ƙaddamar da dumama mataki na farko ya rage raguwa sosai, a ƙarshe ya kawar da su.

Tasirin lokacin dumama mataki na biyu akan haɗin kai bai bayyana ba a cikin gwaje-gwajen orthogonal. Daidaita matsin lamba a 15 kN da lokacin dumama mataki na farko a 90 min, lokacin dumama mataki na biyu na 30, 60, da 90 min duk sun haifar da yadudduka masu yawa mara amfani, yana nuna lokacin dumama mataki na biyu yana da. kadan tasiri a kan bonding.

Mafi kyawun dabi'u don tsarin tsarin haɗin gwiwa sune: matsa lamba 15 kN, lokacin dumama mataki na farko 90 min, matakin farko na zafin jiki 120 ℃, lokacin dumama mataki na biyu 30 min, zazzabi na mataki na biyu 600 ℃, da lokacin riƙewa mataki na biyu. 3 hours.

Lokacin aikawa: Juni-11-2024